There are hundreds of surface treatment options for metal parts. Which one is most suitable for your product? Many factors affect surface treatment, such as material, usage environment, function, appearance, etc.

In the following text, we will teach you how to choose the appropriate surface treatment according to different application scenarios.

What is surface treatment?

Surface finishing refers to creating a protective or functional layer on the surface of metal parts. Common processes include anodizing, electroplating, powder coating, passivation, and sandblasting. These methods improve corrosion resistance, hardness, wear resistance, and visual appearance.

Surface treatment plays a crucial role in enhancing durability and upgrading the appearance of CNC-machined parts. Learn more about our CNC machining services .

Why Surface Finishing Matters?

Take faucets we use daily as an example. A faucet fresh out of the die-casting machine often has a rough surface and dull color, which is quite poor—hardly anyone would want to buy such a product. However, faucets on the market in various specifications and exquisite designs all undergo surface treatment. Surface treatment not only enhances corrosion resistance and extends the product’s lifespan, but also increases its value and, in an intangible way, elevates the brand image. Surface treatment is a reflection of product quality and the foundation of its value.

Common Surface Finishing Methods

Take faucets we use daily as an example. A faucet fresh out of the die-casting machine often has a rough surface and dull color, which is quite poor—hardly anyone would want to buy such a product. However, faucets on the market in various specifications and exquisite designs all undergo surface treatment. Surface treatment not only enhances corrosion resistance and extends the product’s lifespan, but also increases its value and, in an intangible way, elevates the brand image. Surface treatment is a reflection of product quality and the foundation of its value.

Anodizing

Anodizing is a surface treatment process that uses electrochemical principles to form a dense, hard, and corrosion-resistant oxide layer on the surface of aluminum and aluminum alloys. Anodizing is mainly suitable for aluminum and aluminum alloy materials.

Ordinary anodizing (Type II) is typically used for decorative coloring of products. It not only enhances corrosion resistance but also offers a wide range of color options, meeting both aesthetic and functional needs. In contrast, hard anodizing (Type III) is more suitable for mechanical parts, outdoor equipment, and other products with high wear resistance requirements. It can significantly increase surface hardness and durability, providing reliable protection in high-intensity usage environments.

Electroplating

Electroplating is a surface treatment process that uses electrochemical principles to deposit a uniform, dense, and well-adhered metal coating on the surface of metals or other conductive materials. Electroplating is mainly suitable for materials such as steel, copper, and brass, and it is one of the most commonly used surface treatment methods.

There are many types of electroplating processes. For example, chrome plating can enhance surface luster and decorative effect, while nickel plating and zinc plating can significantly improve the material’s corrosion resistance. The chemical coating formed by electroplating is not only uniform and stable but also provides excellent protection and functionality for the substrate. Therefore, electroplating is widely used in automotive parts, daily necessities, electronic components, and many other fields, making it a key process for enhancing both product performance and appearance.

Powder Coating

Powder coating is a surface treatment process in which solid powder is used as the coating material. The powder is applied to the surface through electrostatic attraction and then cured by high-temperature baking, forming a strong, uniform, and corrosion-resistant coating. It is mainly suitable for metals such as aluminum and aluminum alloys, as well as steel.

Powder coatings not only offer excellent wear resistance and UV protection but are also solvent-free, making them more environmentally friendly. In addition, powder coatings provide a wide range of color and texture options, allowing for matte, glossy, textured, and other finishes. As a result, they are widely used in outdoor equipment, consumer electronics housings, home furnishings, and more.

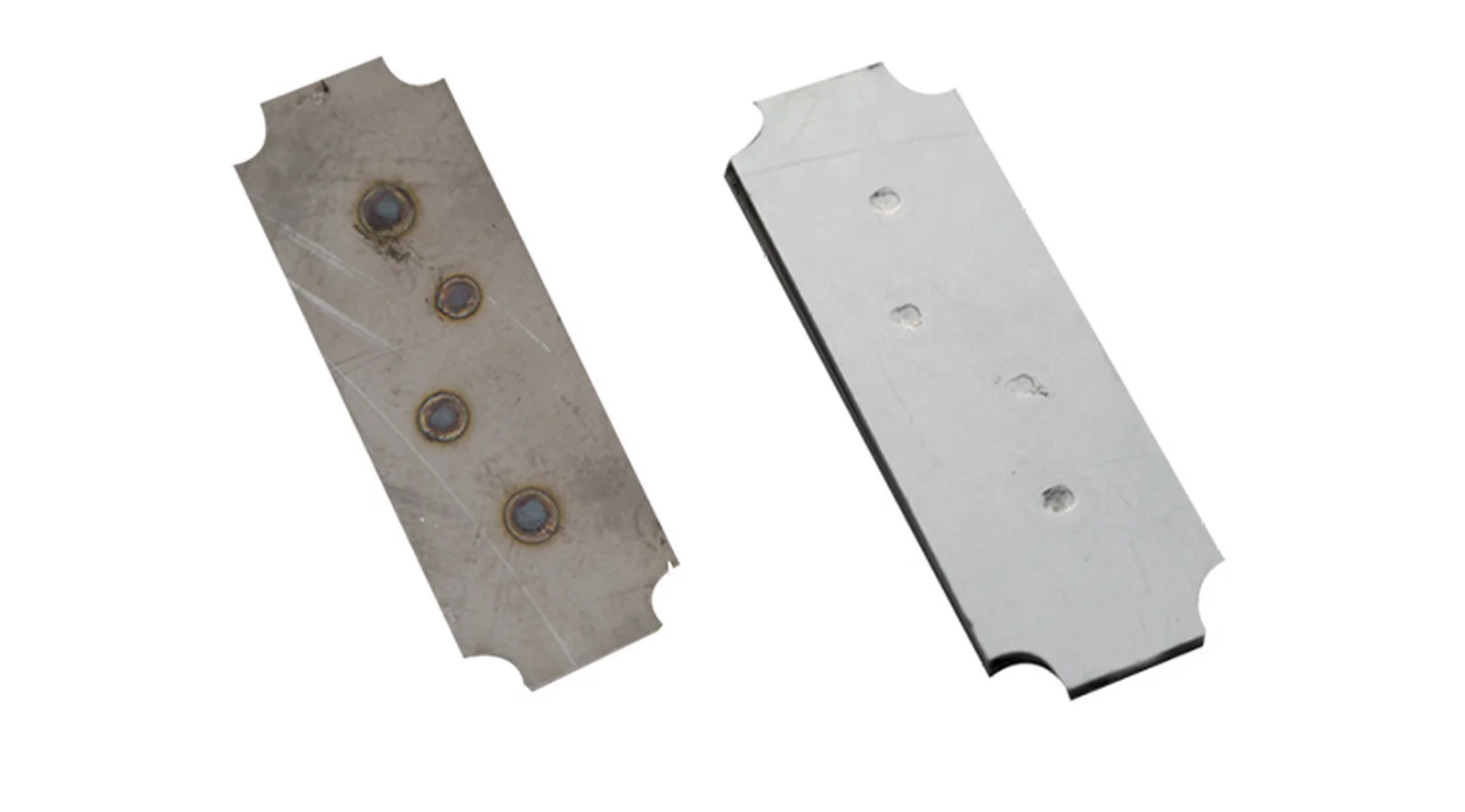

Passivation

Passivation is a surface treatment process that forms a stable, dense, and protective passive layer on the metal surface through chemical treatment, significantly enhancing the material’s corrosion resistance. It is mainly suitable for metals such as stainless steel, aluminum and aluminum alloys, and copper.

Passivation not only improves the product’s corrosion resistance but also enhances the surface condition, making the appearance cleaner and more uniform. Because it does not alter the dimensions and provides strong corrosion protection, passivation is widely used in medical devices, precision components, food equipment, and other high-demand applications.

Sandblasting

Sandblasting is a surface treatment process that uses compressed air to propel abrasive particles (such as glass beads or steel grit) onto the surface of a workpiece to clean, polish, or create a specific surface texture. It is applicable to various metal materials.

Sandblasting can not only remove surface oxides and burrs but also create an appropriate surface roughness on the workpiece, providing good adhesion for subsequent coatings, anodizing, and other treatments.

How to Choose the Right Surface Treatment Method?

With so many surface treatment options available, how do you choose? The following steps can help you quickly make the right decision.

Define the Function

It is essential to fully understand the actual functional requirements of the product. This not only involves clarifying specific needs for wear resistance, corrosion resistance, or insulation, but also considering the product’s usage environment—for example, whether it will be exposed long-term to chemicals, humidity, or high temperatures. At the same time, whether the product’s appearance is critical is also an important factor in choosing a surface treatment method. A comprehensive understanding of these requirements helps effectively narrow down the range of available processes and identify the most suitable surface treatment solution.

Common Surface Treatments for Materials

Different materials require different surface treatment methods. Some processes can be applied to various materials, but choosing an unsuitable treatment not only fails to achieve the desired effect but also increases costs.

Common surface treatments for aluminum and aluminum alloys include anodizing, passivation, powder coating, and painting.

If the treatment method is incompatible with the material, it may cause the coating to peel or crack, affecting product performance and service life. Therefore, when selecting a surface treatment process, it is essential to fully consider the material characteristics and actual usage requirements.

Consider the Usage Environment

In actual production, we often encounter cases where customers overlook the product’s usage environment, leading to issues such as protective layer peeling. For example, in marine environments, aluminum alloy products treated with ordinary anodizing (Type II) may experience surface oxide layer peeling after a period of use. The film thickness of Type II anodizing is usually between 5–25 μm, and the high concentration of chloride ions in seawater can easily penetrate the thin film, potentially causing substrate corrosion over time.

Therefore, when selecting a surface treatment process, it is essential to fully understand the product’s usage environment: is it a normal outdoor environment, a marine environment, a high-wear environment, a high-temperature environment, or a special environment involving exposure to chemicals? Choosing the appropriate surface treatment based on the actual environment can not only effectively extend product life and ensure performance stability but also reduce maintenance costs.

Horizon offers advanced surface finishing capabilities and deep knowledge of complex processes, including:

- Professional anodizing

- Dual-layer electroplating (nickel + chrome)

- Powder coating

- Precision passivation

We evaluate your material and usage requirements during the quotation stage, ensuring optimal quality and cost efficiency.

Contact us today via WhatsApp or Email for expert finishing recommendations.