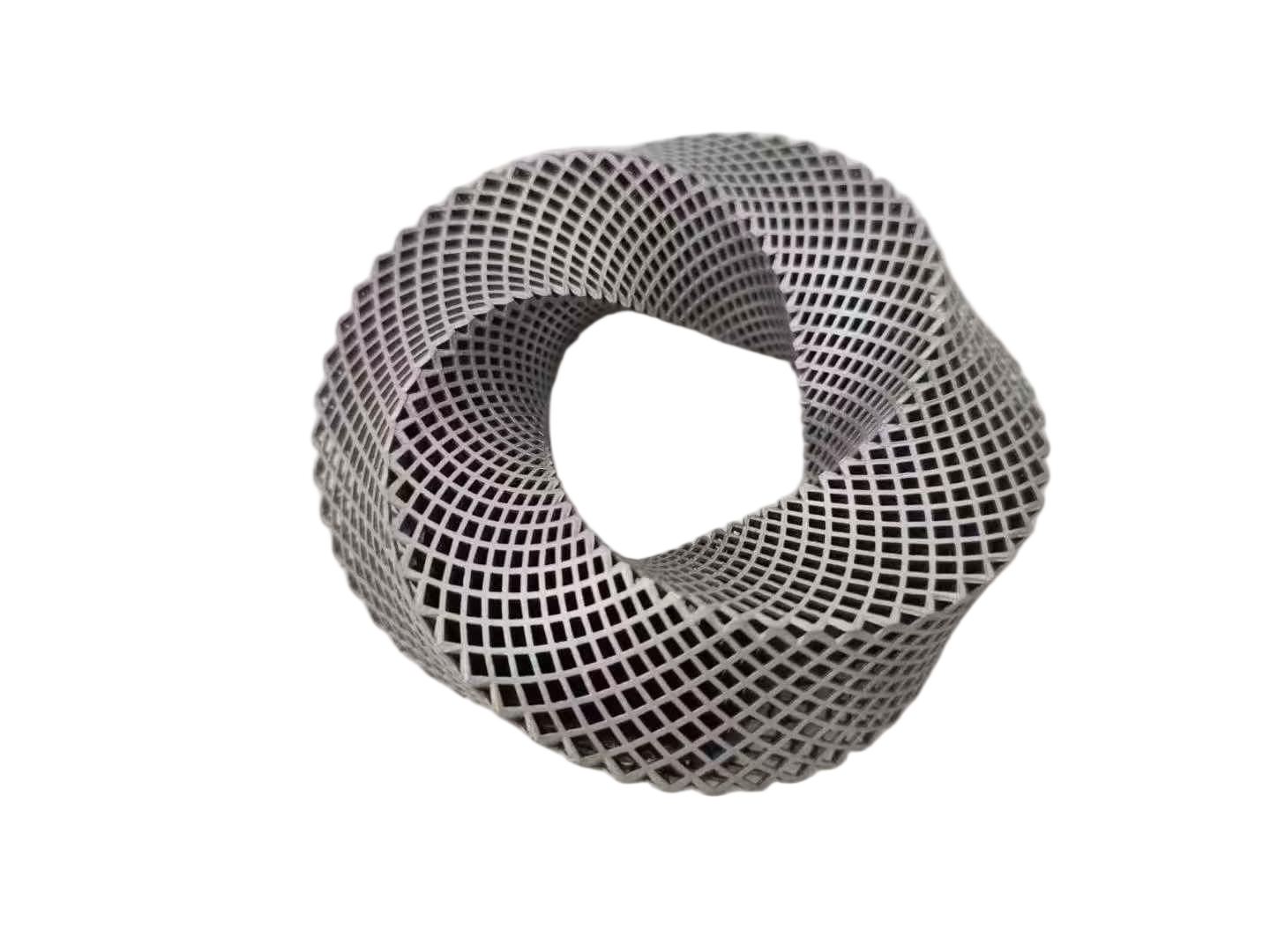

What are Horizon’s custom CNC Machining Services?

Horizon is an ISO 9001:2015 certified manufacturer offering high-precision, high-quality CNC machining services for both metal and plastic parts.

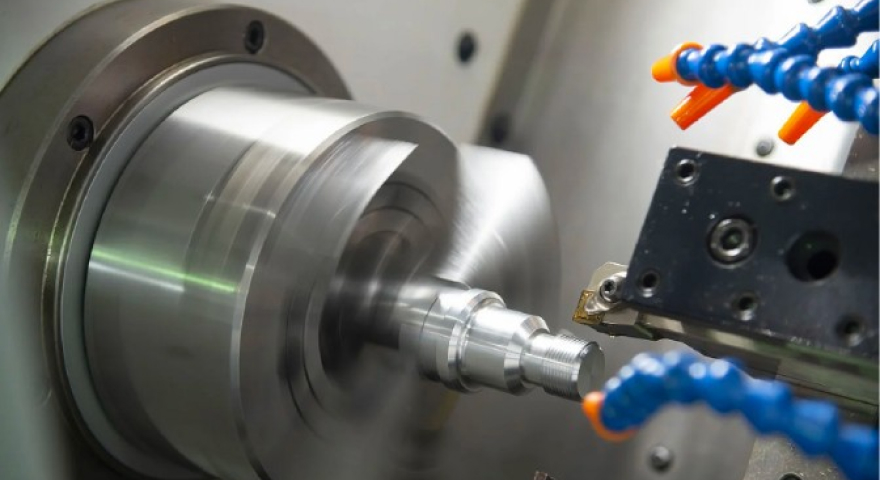

Our capabilities include milling and turning services:

Milling equipment: 3-axis, 4-axis, and 5-axis precision CNC machining.

Turning equipment: automated lathes and turn-mill centers.

Auxiliary processes: EDM (Electrical Discharge Machining).

All processes can achieve strict tolerances of ±0.01 mm.

In addition, we specialize in custom CNC machining, from rapid prototyping and small-batch trial production to full-scale mass production.

We also offer a wide range of surface finishing options — including plating, anodizing, and passivation — with neutral salt spray resistance of over 720 hours, ensuring your parts are not only dimensionally precise but also visually flawless.

Whether you are an individual, a startup, or a global enterprise, Horizon is your trusted partner for on-demand custom CNC machining.

Get your instant quote today!

Our Manufacturing Services

How to Work With Us

Upload a CAD File

To start, simply select a manufacturingprocess and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we’ll send you designfor manufacturability(DFM) analysis andreal-time pricing.

Manufacturing Begins

Once you review your quote and placeyour order, we’ll start the manufacturingprocess. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allowsus to produce parts in as fast as 1 day.

Our CNC Machining Capabilities

Why Choose Horizon?

Not only do we have advanced CNC equipment and years of professional experience in CNC machining, but we also maintain cooperation with over 50 partners. This enables us to seamlessly support every stage, from rapid prototyping and small-batch trial production to large-scale mass production.

Horizon

- Timely response: Get your quotation within as fast as 12 hours.

- Dedicated one-on-one professional customer service.

- Experienced engineering team: Multiple engineers with over 10 years of experience provide one-stop custom machining solutions (DFM), recommending optimized processes and materials tailored to your needs.

- Free 2D drawing redrawing services.

- Capability to handle complex multi-process projects, such as combining CNC machining, turning, sheet metal, silicone molding, and conductive silicone die-cutting within a single project.

- A comprehensive after-sales team dedicated to promptly resolving customer inquiries.

- We customize suitable packaging methods based on the product, such as blister packs, bubble bags, etc., allowing easy visibility upon opening.

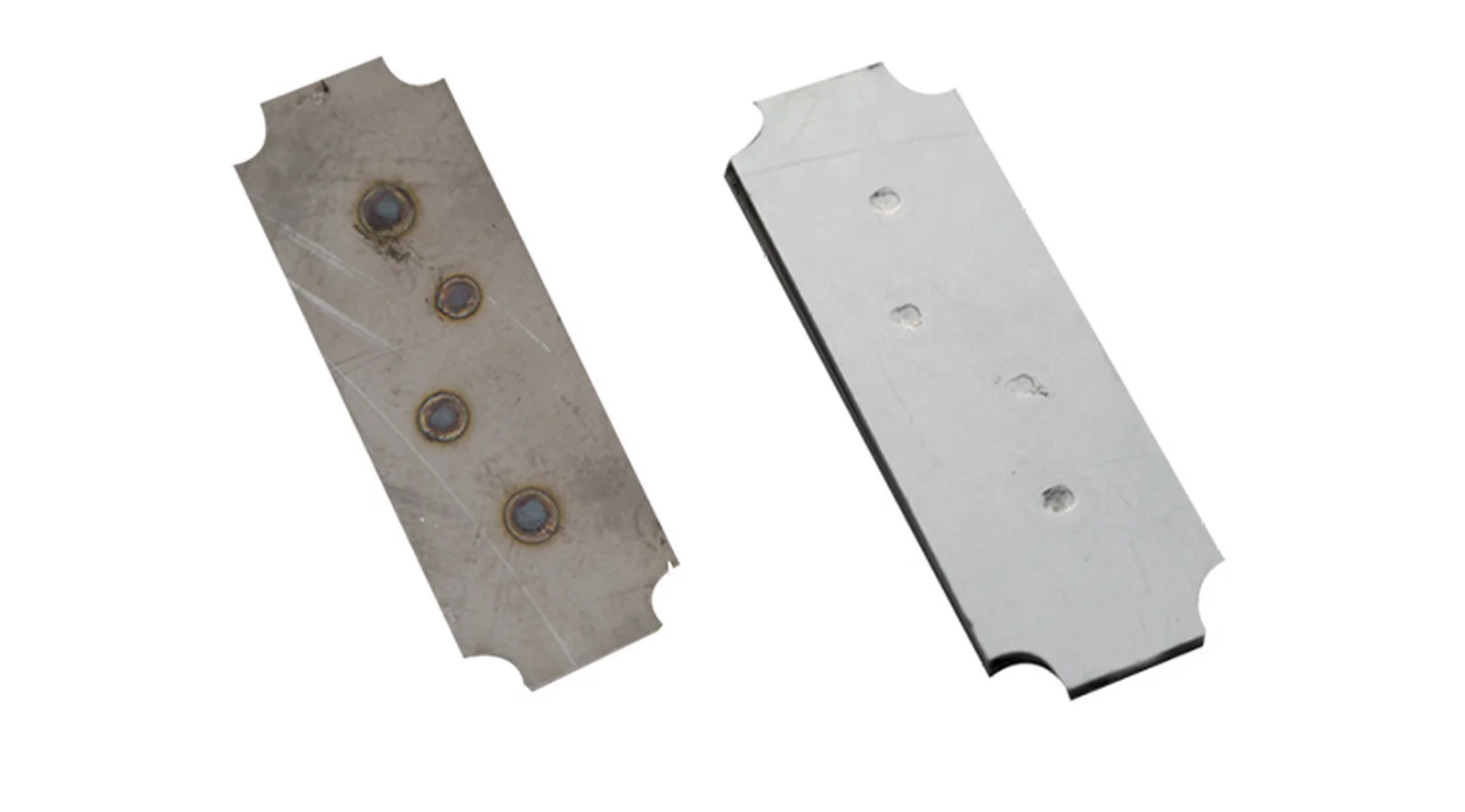

- For high-quality products, our quality inspection process remains consistent throughout: IQC, IPQC, PQC, FQC, and OQC.

Other CNC Machining Companies

- Slow response time: Quotations may take 24 hours or longer.

- Customer service lacks sufficient expertise, making communication difficult.

- Engineering team capabilities are limited, with narrow material knowledge and single-process focus, unable to quickly recommend optimized processes and materials tailored to your needs.

- 2D drawing redrawing services are charged, starting at $100 USD.

- Limited supply chain: Unable to handle multiple processes in-house, requiring projects to be split across several companies, which increases both communication overhead and overall order costs.

- Lack of an after-sales team results in delayed responses to customer concerns.

- Suitable for stretch film wrapping, but removal is difficult, time-consuming, and labor-intensive.

- Only IQC and OQC inspections are performed.

CNC Machining Materials

Metals

Inconel

Inconel Superalloy Materials Inconel alloys are a family of high-performance nickel-chromium superalloys known for their exceptional strength, oxidation resistance, and high-temperature stability. These alloys are widely used in extreme environments where components are subjected to high temperatures, pressure, or mechanical loads.

Magnesium

Magnesium & Magnesium Alloy Materials Magnesium (Mg) and its alloys are among the lightest structural metals available, offering exceptional strength-to-weight ratio, good thermal conductivity, and beneficial vibration-damping properties. These materials are increasingly attractive for advanced engineering uses such as aerospace, automotive, and electronics applications where weight reduction is critical.

Titanium

Titanium Titanium is a lightweight yet high-strength metal known for its exceptional strength-to-weight ratio, excellent corrosion resistance, and outstanding biocompatibility. It maintains stable mechanical properties across high and low temperatures and features a low thermal expansion coefficient, making it ideal for demanding applications. Thanks to these superior properties, titanium and titanium alloys are widely used

Steel Mild Low Carbon

Low-Carbon (Mild) Steel Material Low-carbon steel is a type of carbon steel with low carbon content, typically referring to steel materials with a carbon content ranging from 0.02% to 0.30%. Due to its low carbon content, it is also known as “mild steel.” Its performance characteristics are particularly notable: compared to medium-carbon steel and high-carbon

Stainless Steel

Stainless Steel Material & Alloys Stainless steel is a family of corrosion-resistant iron alloys developed to withstand oxidation, corrosion, and wear. Thanks to its excellent durability, mechanical strength, and versatile formability, stainless steel is widely used across industries requiring long-term performance—even in harsh or aggressive environments. Its favorable operational and welding properties can fully meet

Copper

Copper Material & Copper Alloys Copper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile. Its glossy orange-red appearance is instantly recognizable, and the metal remains aesthetically appealing even during its natural oxidation process—where environmental reactions form a bluish-green coating known as patina. However, it should be noted that copper’s weldability is

Brass

Brass Material & Brass Alloys Explore HorizonRP’s brass materials—offering excellent machinability, corrosion resistance, and attractive appearance. Ideal for hardware, plumbing, decorative, electrical, and industrial applications. Brass is an alloy composed of copper and zinc, with a golden color and excellent weather and corrosion resistance. Its tensile strength is comparable to that of mild steel. In

Aluminum

Aluminum Material & Aluminum Alloys Aluminum is highly favored in CNC machining due to its low density, excellent mechanical properties, superior thermal and electrical conductivity, and outstanding corrosion resistance. Among aluminum alloys, 6061-T651, 7075-T651, and 2024-T351 are widely used for their ideal balance of strength, machinability, and cost.

Plastics

ABS

ABS (Acrylonitrile Butadiene Styrene) Material ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent balance of strength, toughness, and processability. Because it combines rigidity from acrylonitrile and styrene with impact resistance from butadiene, ABS is commonly used in consumer products, enclosures, housings, and structural components.

HDPE

HDPE (High-Density Polyethylene) Material High-Density Polyethylene (HDPE) is a thermoplastic polymer with high strength-to-density ratio, known for durability, chemical resistance, and ease of processing. As a semi-crystalline plastic, it offers excellent impact performance, low moisture uptake, and good machinability — making it a popular choice in industrial, chemical, packaging, and structural applications. It is great

HIPS

HIPS (High Impact Polystyrene) Material HIPS, or High Impact Polystyrene, is a modified polystyrene polymer enhanced with rubber modifiers (usually polybutadiene) to improve toughness and durability. The result is a rigid yet impact-resistant thermoplastic that retains good processability, making it popular in prototyping, manufacturing, and consumer products. HIPS combines the stiffness of polystyrene with improved

POM

POM (Polyoxymethylene / Acetal) Engineering Material POM (polyoxymethylene), also known as acetal, is a high‑performance engineering thermoplastic valued for its rigidity, low friction, excellent wear resistance, and good dimensional stability. It is often used in precision mechanical parts that require durable, low‑maintenance performance.

Nylon

Nylon (Polyamide) Engineering Material Nylon (polyamide) is a versatile engineering thermoplastic known for its high strength, excellent wear resistance, good chemical stability, and toughness. It is widely used across industries for gears, bearings, bushings, automotive components, industrial parts, and more. Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications

PEEK

PEEK (Polyetheretherketone) Engineering Material PEEK (polyetheretherketone) is a premium thermoplastic widely recognized for its exceptional thermal stability, mechanical strength, chemical resistance, dimensional stability, and in many cases biocompatibility and electrical insulation. It is used in extreme environments like aerospace, medical implants, electronics, and semiconductor industries.

PMMA (Acrylic)

PMMA (Acrylic) Engineering Material Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical

PC

PC (Polycarbonate) Engineering Material PC (polycarbonate) is a versatile engineering plastic known for its high impact resistance, optical transparency, and good thermal stability. It combines toughness, heat resistance, and aesthetic clarity, making it suitable for a wide array of applications.

PVC

PVC (Polyvinyl Chloride) Plastic Material Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as

PET

PET PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PP

PP Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

LDPE

LDPE Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PTFE

PTFE Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer. It is frequently used in mechanical components requiring reduced friction and wear—such as bearings, gears, and piston rings—due to its non-stick properties, low friction characteristics, and self-lubricating capabilities. PTFE also exhibits excellent electrical insulation properties, making it highly suitable for applications like high-frequency cables,

PEI

PEI (Polyetherimide) Engineering Material PEI (polyetherimide) is a high-performance thermoplastic known for excellent heat resistance, mechanical strength, and chemical stability. It is widely used in demanding applications across aerospace, electronics, medical, and industrial fields.

PC+GF

PC+GF(Glass‑Fiber Reinforced Polycarbonate) Material PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making

CPVC

CPVC (Chlorinated Polyvinyl Chloride) Plastic Material CPVC (Chlorinated Polyvinyl Chloride) is a modified form of PVC, with enhanced thermal stability, mechanical properties, and chemical resistance. These upgraded characteristics make CPVC an excellent choice for applications in high-temperature and corrosive environments where ordinary PVC would fail.

PC+ABS

PC/ABS (Polycarbonate‑ABS Blend) Plastic Material PC+ABS is a blend-modified material that combines the advantages of both materials. It not only inherits the high impact resistance of PC but also the material strength of ABS, while improving its heat resistance. It is often used in electronic product casings, automotive interiors, consumer products, and more.

TPU

Thermoplastic Polyurethane (TPU) for CNC Machining HorizonRP offers high-quality Thermoplastic Polyurethane (TPU) material, known for its flexibility, durability, and resistance to abrasion and chemicals. Ideal for CNC machining applications, TPU is widely used across various industries, including automotive, medical, and consumer electronics.

Tolerances without individual tolerance indications according to ISO 2768-1:1989. Values in millimeters.

| Basic size range | f (fine) | m (medium) | c (coarse) | v (very coarse) |

|---|---|---|---|---|

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | — |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over 2000 up to 4000 | – | ±2.0 | ±4.0 | ±8.0 |

Tolerances for CNC Machining

Horizon applies the ISO 2768-m (medium) standard for machined plastics and the ISO 2768-f (fine) standard for machined metals. Under normal circumstances, CNC machining tolerances can be controlled within the range of ±0.125 mm (±0.005″) to ±0.05 mm (±0.002″). For tighter tolerances, please provide fully detailed 2D drawings. Our engineering team will confirm the critical dimensional requirements with you and strive to achieve the highest precision possible. If 2D drawings are not available, we will apply the ISO 2768-m (medium) standard for machined parts.

Surface Finish and Post-Processing Options

As machined

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

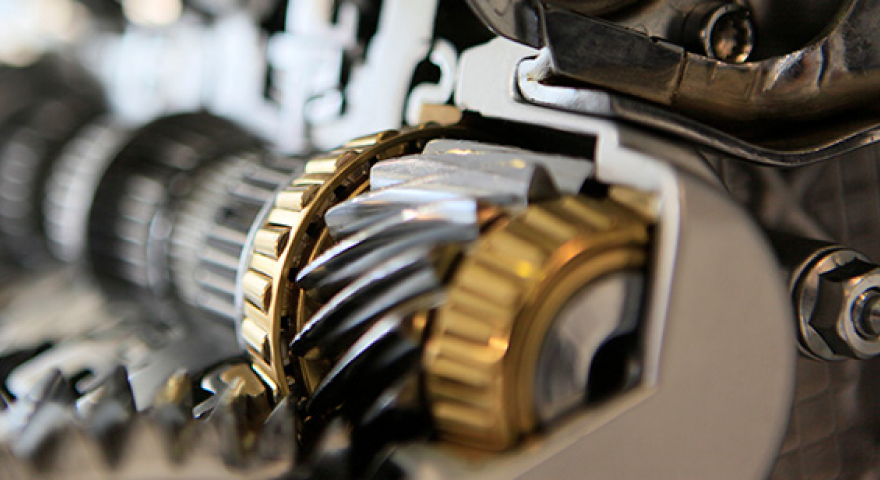

CNC Machining for Various Industrial Applications

Consumer Electronics

Prototyping and on-demand production of consumer electronics products

Customer Success Stories

Crafted with precision and intelligence for beautiful, durable products

Smart Home Industry

A Bespoke Pendant Light: Crafting Perfection Through Innovation and Dedication

Home & Décor Industry

Customer Reviews

Your questions, answered

CNC machining offers key advantages over 3D printing, injection molding, and laser cutting:

It’s fast and cost-effective for simple parts, like base plates with holes or grooves. CNC machines achieve tight tolerances of ±0.01 mm and deliver smooth surface finishes down to Ra 0.8—ideal for painting or anodizing. They also handle a wide range of part sizes, from large components up to 6 m x 30 m to tiny features cut with 0.05 mm tools on precision 5-axis mills.

CNC (Computer Numerical Control) machining is a precise and efficient manufacturing process that uses automated cutting tools to shape metal or plastic parts. Depending on part complexity, we use 3-axis, 4-axis, or 5-axis milling machines, lathes, or routers. Once we receive your 3D CAD model, our skilled machinists program optimized tool paths to reduce costs and ensure tight tolerances. Learn more about the CNC machining process.