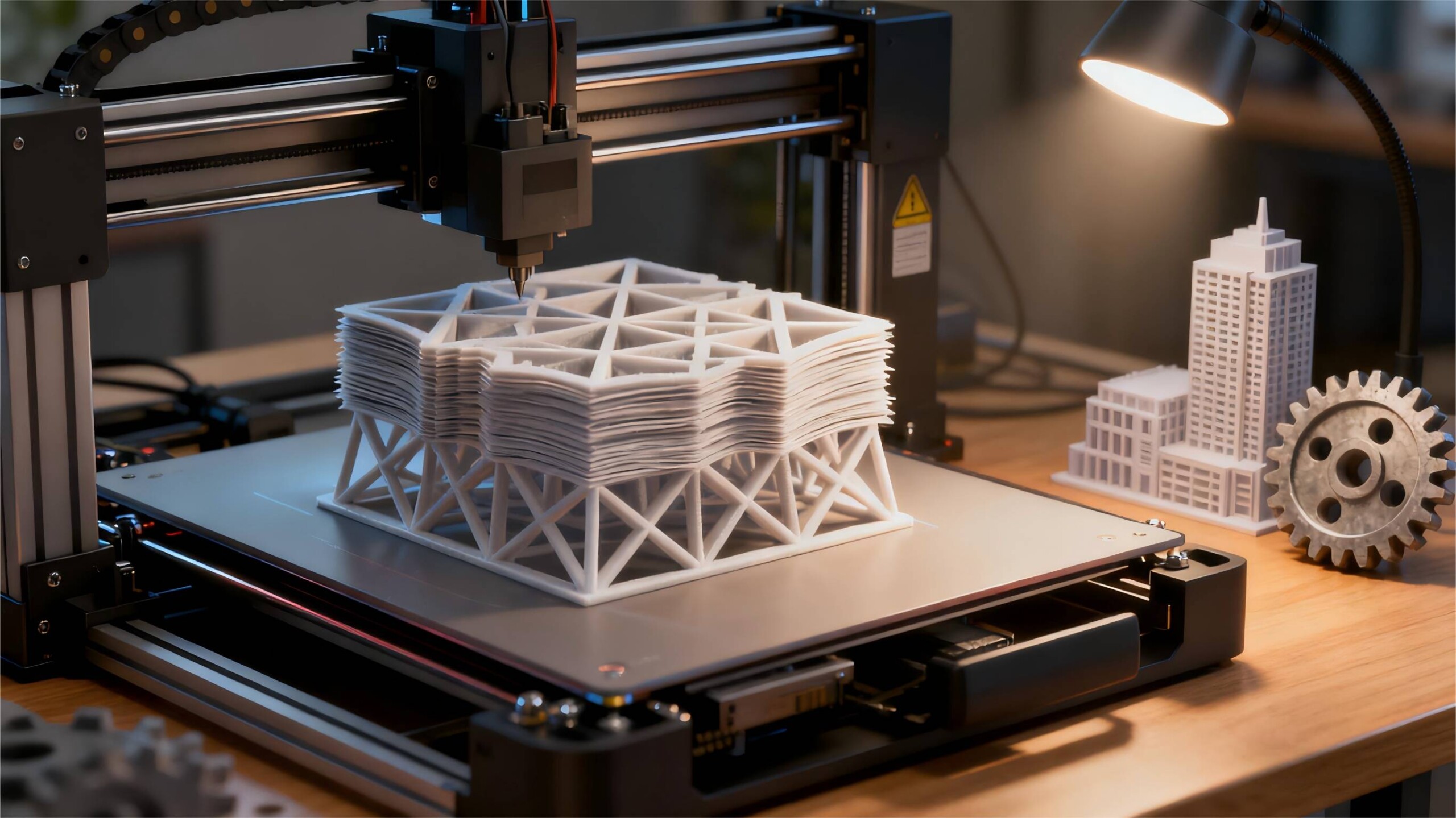

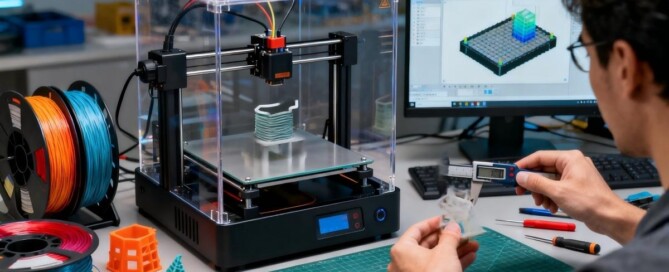

why choose 3D printing?

In recent years, 3D printing (Additive Manufacturing) has gradually moved from a niche maker community into the public eye: from product design and medical technology to classroom education and even home DIY, its presence can be seen everywhere. Not only are there multiple additive technologies, but a wide range of materials is