Flexible Custom 5-Axis CNC Machining Services

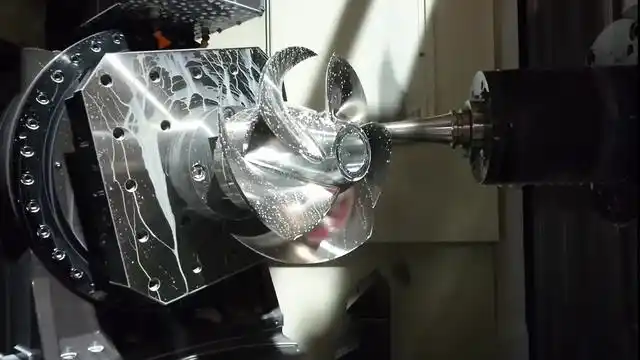

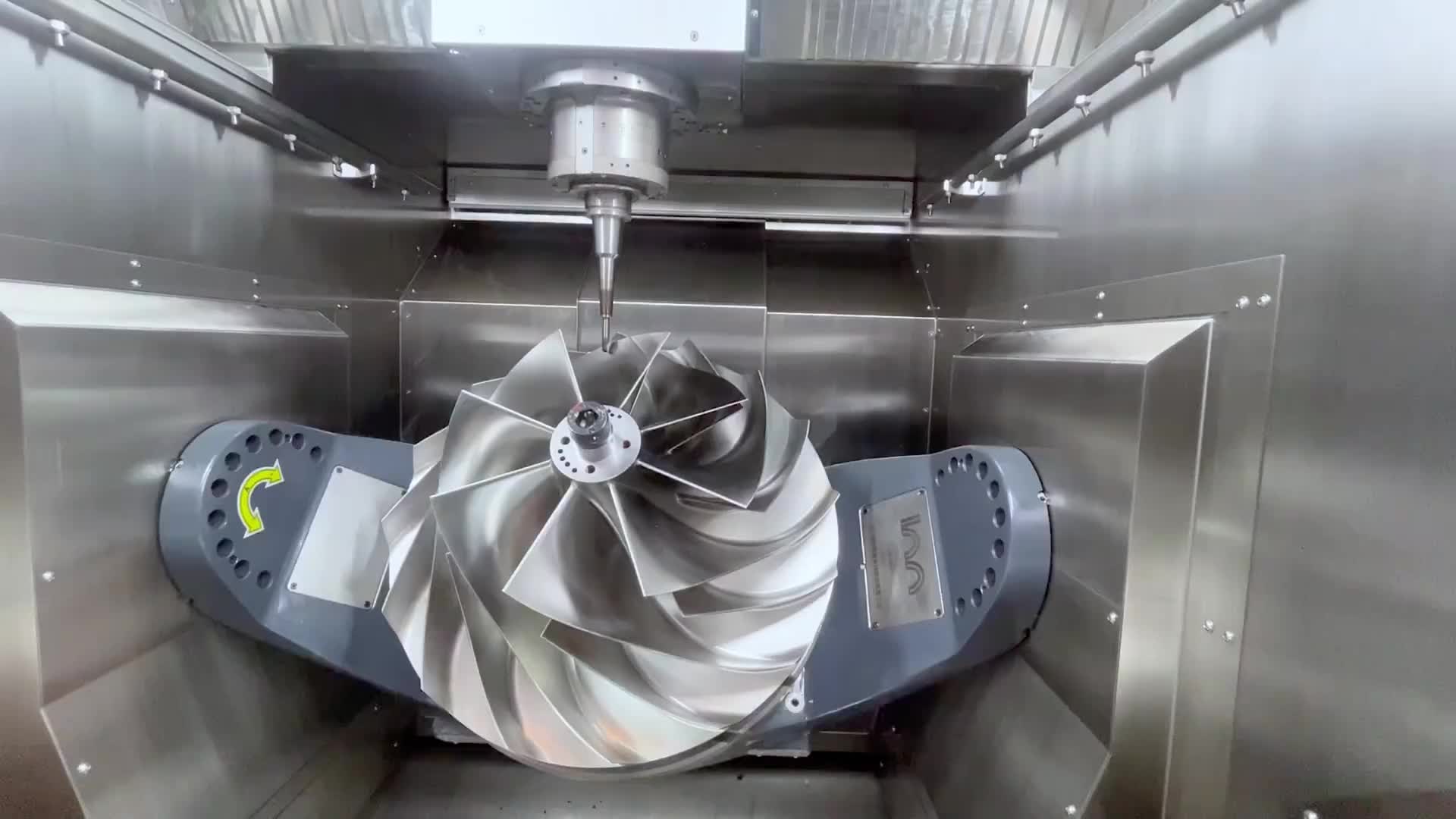

Horizon offers advanced 5-axis CNC machining services capable of producing complex, high-precision components with exceptional surface finishes. This technology enables the accurate machining of intricate geometries and tight-tolerance features, fully meeting demanding design requirements.

What is 5-axis Machining?

5-Axis CNC machining is an advanced manufacturing process that allows cutting tools to move simultaneously along five different axes. This capability is essential for efficiently producing complex, high-precision parts while minimizing setups and ensuring consistent accuracy. Industries such as aerospace, automotive, and medical device manufacturing rely heavily on 5-axis machining to create intricate components that demand exceptional precision and surface quality.

Key Advantages of Five-Axis CNC:

- Efficient machining of complex parts

- Fewer setups and reduced errors

- Greater accuracy and superior surface finish

- Improved overall productivity

We offer the most comprehensive custom machining service, from prototypes delivered in a single day to complex parts at production volumes. In addition to our vast machining capabilities, our global network offers solutions for larger, more complex parts and tighter tolerances, with most orders quoted instantly.

How to Work With Us

How to Work With Us

Our ordering process

Why Choose 5-Axis Machining with Horizon

With numerous precision machining providers to choose from, why should you partner with Horizon? Here are four key reasons that set us apart:

3+2 Axis Machining Vs Simultaneous

Strictly speaking, 3+2 axis machining also uses five axes, but it differs from true simultaneous 5-axis machining. In 3+2 machining, the cutting tool is positioned using two rotary axes before the three linear axes perform the cutting. In contrast, simultaneous 5-axis machining moves all five axes at once, allowing for faster production and superior surface quality on complex, contoured parts.

Feature

Simultaneous 5-Axis Machining

3+2 Axis Machining

Movement

Simultaneous 5-axis machining continuously moves all axes, allowing the cutting tool to glide smoothly between passes for faster, more efficient production.

In 3+2 axis machining, the cutting tool moves along the X, Y, and Z axes while the fourth and fifth axes adjust to a fixed angle. Although this method can be slower than simultaneous five-axis CNC, it improves part rigidity and extends tool life.

Suitable Parts

Highly complex parts with continuous surfaces and high precision

Complex parts with limited continuous surfaces

Efficiency

Multiple setups often required

Most operations completed in a single setup, faster production

Surface Quality

Produces smoother finishes with fewer tool marks

May require additional finishing due to repositioning

Tool Load & Life

Optimized cutting angles reduce vibration, extend tool life

Cutting force concentrated due to fixed angles

Cost

Higher initial cost, ideal for high-precision and complex parts

Relatively lower, suitable for moderately complex parts

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

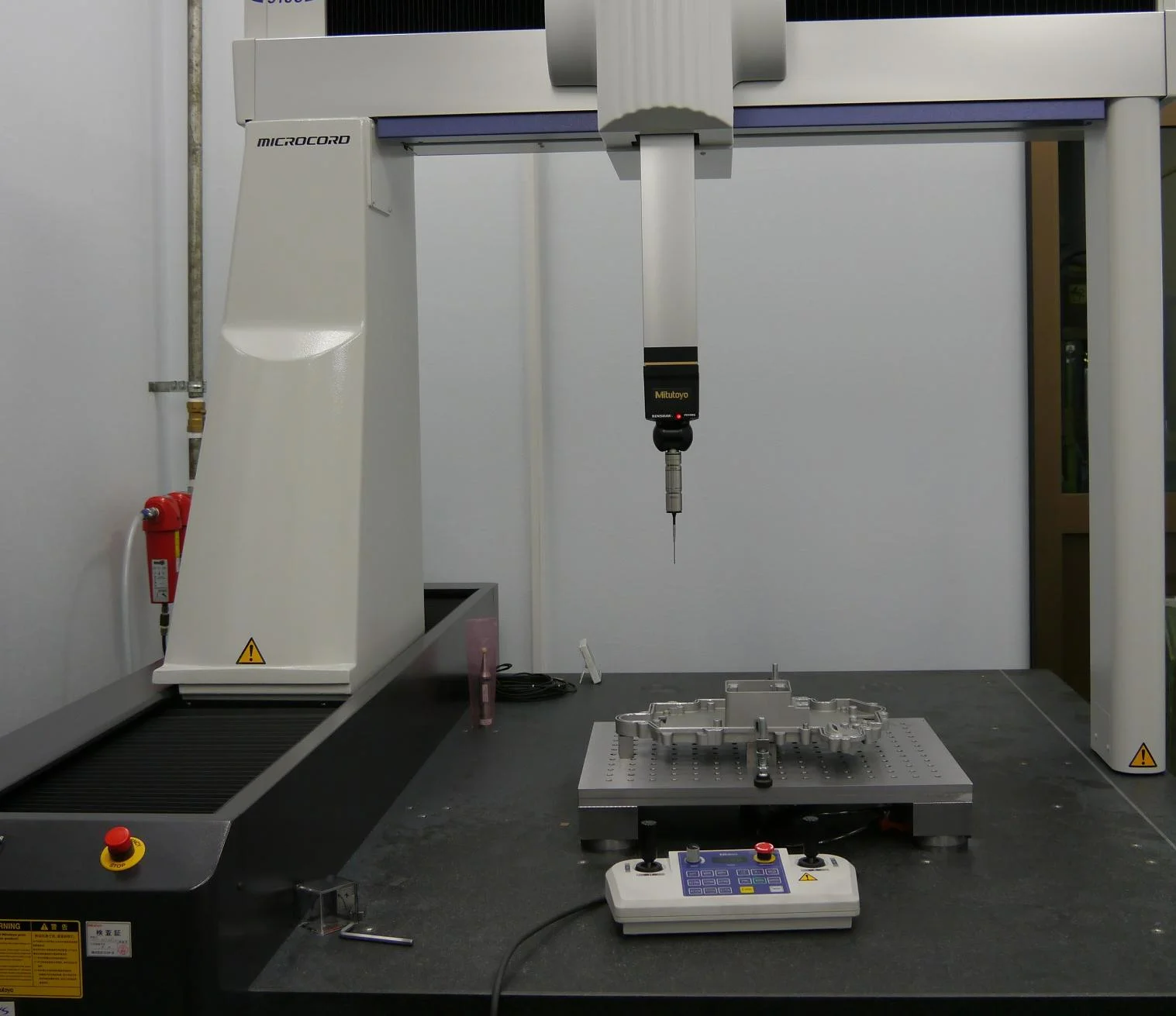

| 1 | Advanced Inspection Equipment | ||||

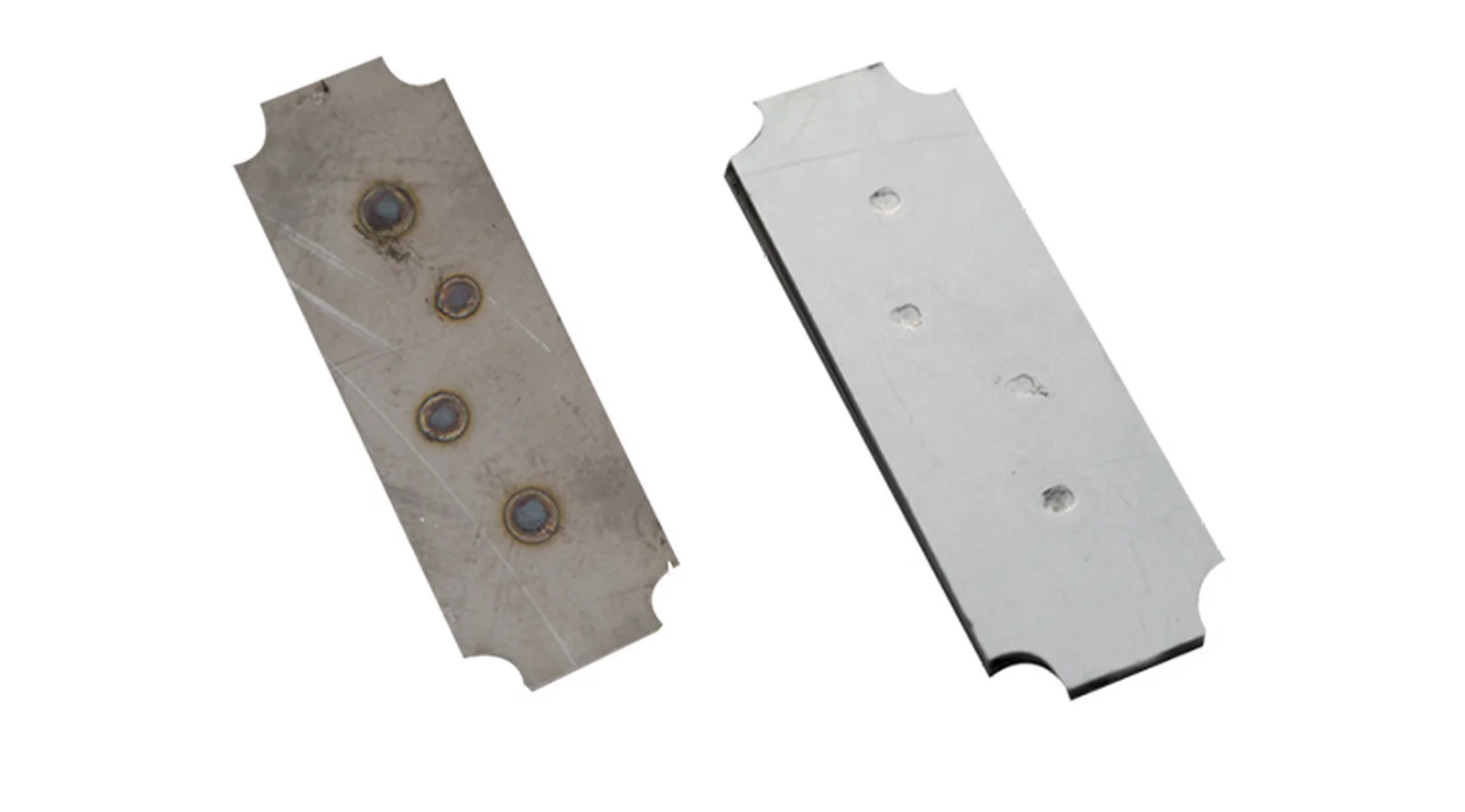

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

Materials Used in 5-Axis CNC Projects

Beyond a well-designed engineering plan, choosing the right material can significantly reduce overall costs. Horizon offers a wide range of material options to suit different project needs. If you need guidance in selecting the most suitable material for your 5-axis CNC project, feel free to contact us—our experts are here to help!

Metal

Inconel

Inconel Superalloy Materials Inconel alloys are a family of high-performance nickel-chromium superalloys known for their exceptional strength, oxidation resistance, and high-temperature stability. These alloys are widely used in extreme environments where components are subjected to high temperatures, pressure, or mechanical loads.

Magnesium

Magnesium & Magnesium Alloy Materials Magnesium (Mg) and its alloys are among the lightest structural metals available, offering exceptional strength-to-weight ratio, good thermal conductivity, and beneficial vibration-damping properties. These materials are increasingly attractive for advanced engineering uses such as aerospace, automotive, and electronics applications where weight reduction is critical.

Titanium

Titanium Titanium is a lightweight yet high-strength metal known for its exceptional strength-to-weight ratio, excellent corrosion resistance, and outstanding biocompatibility. It maintains stable mechanical properties across high and low temperatures and features a low thermal expansion coefficient, making it ideal for demanding applications. Thanks to these superior properties, titanium and titanium alloys are widely used

Steel Mild Low Carbon

Low-Carbon (Mild) Steel Material Low-carbon steel is a type of carbon steel with low carbon content, typically referring to steel materials with a carbon content ranging from 0.02% to 0.30%. Due to its low carbon content, it is also known as “mild steel.” Its performance characteristics are particularly notable: compared to medium-carbon steel and high-carbon

Stainless Steel

Stainless Steel Material & Alloys Stainless steel is a family of corrosion-resistant iron alloys developed to withstand oxidation, corrosion, and wear. Thanks to its excellent durability, mechanical strength, and versatile formability, stainless steel is widely used across industries requiring long-term performance—even in harsh or aggressive environments. Its favorable operational and welding properties can fully meet

Copper

Copper Material & Copper Alloys Copper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile. Its glossy orange-red appearance is instantly recognizable, and the metal remains aesthetically appealing even during its natural oxidation process—where environmental reactions form a bluish-green coating known as patina. However, it should be noted that copper’s weldability is

Brass

Brass Material & Brass Alloys Explore HorizonRP’s brass materials—offering excellent machinability, corrosion resistance, and attractive appearance. Ideal for hardware, plumbing, decorative, electrical, and industrial applications. Brass is an alloy composed of copper and zinc, with a golden color and excellent weather and corrosion resistance. Its tensile strength is comparable to that of mild steel. In

Aluminum

Aluminum Material & Aluminum Alloys Aluminum is highly favored in CNC machining due to its low density, excellent mechanical properties, superior thermal and electrical conductivity, and outstanding corrosion resistance. Among aluminum alloys, 6061-T651, 7075-T651, and 2024-T351 are widely used for their ideal balance of strength, machinability, and cost.

Plastic

PC+ABS

PC/ABS (Polycarbonate‑ABS Blend) Plastic Material PC+ABS is a blend-modified material that combines the advantages of both materials. It not only inherits the high impact resistance of PC but also the material strength of ABS, while improving its heat resistance. It is often used in electronic product casings, automotive interiors, consumer products, and more.

CPVC

CPVC (Chlorinated Polyvinyl Chloride) Plastic Material CPVC (Chlorinated Polyvinyl Chloride) is a modified form of PVC, with enhanced thermal stability, mechanical properties, and chemical resistance. These upgraded characteristics make CPVC an excellent choice for applications in high-temperature and corrosive environments where ordinary PVC would fail.

PC+GF

PC+GF(Glass‑Fiber Reinforced Polycarbonate) Material PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making

PEI

PEI (Polyetherimide) Engineering Material PEI (polyetherimide) is a high-performance thermoplastic known for excellent heat resistance, mechanical strength, and chemical stability. It is widely used in demanding applications across aerospace, electronics, medical, and industrial fields.

PTFE

PTFE Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer. It is frequently used in mechanical components requiring reduced friction and wear—such as bearings, gears, and piston rings—due to its non-stick properties, low friction characteristics, and self-lubricating capabilities. PTFE also exhibits excellent electrical insulation properties, making it highly suitable for applications like high-frequency cables,

LDPE

LDPE Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PP

PP Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

PET

PET PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PVC

PVC (Polyvinyl Chloride) Plastic Material Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as

PC

PC (Polycarbonate) Engineering Material PC (polycarbonate) is a versatile engineering plastic known for its high impact resistance, optical transparency, and good thermal stability. It combines toughness, heat resistance, and aesthetic clarity, making it suitable for a wide array of applications.

PMMA (Acrylic)

PMMA (Acrylic) Engineering Material Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical

PEEK

PEEK (Polyetheretherketone) Engineering Material PEEK (polyetheretherketone) is a premium thermoplastic widely recognized for its exceptional thermal stability, mechanical strength, chemical resistance, dimensional stability, and in many cases biocompatibility and electrical insulation. It is used in extreme environments like aerospace, medical implants, electronics, and semiconductor industries.

Nylon

Nylon (Polyamide) Engineering Material Nylon (polyamide) is a versatile engineering thermoplastic known for its high strength, excellent wear resistance, good chemical stability, and toughness. It is widely used across industries for gears, bearings, bushings, automotive components, industrial parts, and more. Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications

POM

POM (Polyoxymethylene / Acetal) Engineering Material POM (polyoxymethylene), also known as acetal, is a high‑performance engineering thermoplastic valued for its rigidity, low friction, excellent wear resistance, and good dimensional stability. It is often used in precision mechanical parts that require durable, low‑maintenance performance.

HIPS

HIPS (High Impact Polystyrene) Material HIPS, or High Impact Polystyrene, is a modified polystyrene polymer enhanced with rubber modifiers (usually polybutadiene) to improve toughness and durability. The result is a rigid yet impact-resistant thermoplastic that retains good processability, making it popular in prototyping, manufacturing, and consumer products. HIPS combines the stiffness of polystyrene with improved

HDPE

HDPE (High-Density Polyethylene) Material High-Density Polyethylene (HDPE) is a thermoplastic polymer with high strength-to-density ratio, known for durability, chemical resistance, and ease of processing. As a semi-crystalline plastic, it offers excellent impact performance, low moisture uptake, and good machinability — making it a popular choice in industrial, chemical, packaging, and structural applications. It is great

ABS

ABS (Acrylonitrile Butadiene Styrene) Material ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent balance of strength, toughness, and processability. Because it combines rigidity from acrylonitrile and styrene with impact resistance from butadiene, ABS is commonly used in consumer products, enclosures, housings, and structural components.

Trunnion vs.Swivel-Rotate:Comparing 5-Axis Machine styles

5 axis CNC machines can have different configurations. All have spindles thattravel along the X, Y and Z axes, but machines can add the two “extra” axes indifferent ways, The most common types of 5-axis CNC machine are trunnion-style machines and swivel-rotate-style machines, Some machines combinefeatures of both.

Trunnion Style 5-Axis Machine

Swivel Rotate Style 5-Axis Machine

Workpiece Movement

Moving table (tilts and rotates)

Stationary table, moving spindle

Axis Configuration

A-Axis (tilt), C-Axis (rotate)

B-Axis (tilt), C-Axis (rotate)

Tool Length

Requires longer tools

Uses shorter tools

Machining stability

Moderate (depends on table weight limit)

High (stable table, reduced vibration)

Surface Finish and Post-Processing Options

As machined

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

CNC Machining for Various Industrial Applications

Consumer Electronics

Prototyping and on-demand production of consumer electronics products.