Our injection Molding Capabilities

Horizon makes your transition from prototype design to mass production molds faster and more efficient.Backed by a nationwide network of trusted suppliers and injection molding machines ranging from 90 to 800 tons, we can deliver high-quality, cost-effective plastic parts within just a few days.Our services cover precision mold manufacturing, overmolding, and insert molding, all supported by a team of professional engineers.With Horizon’s one-stop production workflow, you can accelerate time-to-market, ensure product consistency, and maintain cost efficiency while keeping the flexibility to scale production as needed.

Why Choose Horizon?

Why Choose Injection Molding?

Precision Molding, Fast Results

Injection molding is the go-to solution for producing high-quality plastic parts at scale. By injecting molten plastic or metal into precision molds and rapidly cooling them, this process delivers consistent, durable parts with flawless finishes—fast.

Higher Volumes, Lower Costs

While injection molding requires an initial investment in tooling, the cost per part drops dramatically in high-volume production, making it the most cost-effective choice for mass manufacturing.

Endless Material & Color Options

Our injection molding supports a wide range of materials—including thermoplastics, thermosets, and select metals—and allows customization with pigments and functional additives.

Unmatched Consistency & Repeatability

With the same mold used throughout production, every part achieves unmatched consistency and repeatability.

How Does Horizon Injection Molding Process Work

How Does Horizon Injection Molding Process Work

At Horizon, custom injection molding has never been easier or more efficient.

We provide a full end-to-end service—from online quoting to mass production part delivery—powered by a precise, fast, and reliable manufacturing system that helps you bring products to market faster.

Our ordering process

Injection Molding Materials

TPU

Thermoplastic Polyurethane (TPU) for CNC Machining HorizonRP offers high-quality Thermoplastic Polyurethane (TPU) material, known for its flexibility, durability, and resistance to abrasion and chemicals. Ideal for CNC machining applications, TPU is widely used across various industries, including automotive, medical, and consumer electronics.

PC+ABS

PC/ABS (Polycarbonate‑ABS Blend) Plastic Material PC+ABS is a blend-modified material that combines the advantages of both materials. It not only inherits the high impact resistance of PC but also the material strength of ABS, while improving its heat resistance. It is often used in electronic product casings, automotive interiors, consumer products, and more.

CPVC

CPVC (Chlorinated Polyvinyl Chloride) Plastic Material CPVC (Chlorinated Polyvinyl Chloride) is a modified form of PVC, with enhanced thermal stability, mechanical properties, and chemical resistance. These upgraded characteristics make CPVC an excellent choice for applications in high-temperature and corrosive environments where ordinary PVC would fail.

PC+GF

PC+GF(Glass‑Fiber Reinforced Polycarbonate) Material PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making

PEI

PEI (Polyetherimide) Engineering Material PEI (polyetherimide) is a high-performance thermoplastic known for excellent heat resistance, mechanical strength, and chemical stability. It is widely used in demanding applications across aerospace, electronics, medical, and industrial fields.

PTFE

PTFE Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer. It is frequently used in mechanical components requiring reduced friction and wear—such as bearings, gears, and piston rings—due to its non-stick properties, low friction characteristics, and self-lubricating capabilities. PTFE also exhibits excellent electrical insulation properties, making it highly suitable for applications like high-frequency cables,

LDPE

LDPE Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PP

PP Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

PET

PET PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PVC

PVC (Polyvinyl Chloride) Plastic Material Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as

PC

PC (Polycarbonate) Engineering Material PC (polycarbonate) is a versatile engineering plastic known for its high impact resistance, optical transparency, and good thermal stability. It combines toughness, heat resistance, and aesthetic clarity, making it suitable for a wide array of applications.

PMMA (Acrylic)

PMMA (Acrylic) Engineering Material Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical

PEEK

PEEK (Polyetheretherketone) Engineering Material PEEK (polyetheretherketone) is a premium thermoplastic widely recognized for its exceptional thermal stability, mechanical strength, chemical resistance, dimensional stability, and in many cases biocompatibility and electrical insulation. It is used in extreme environments like aerospace, medical implants, electronics, and semiconductor industries.

Nylon

Nylon (Polyamide) Engineering Material Nylon (polyamide) is a versatile engineering thermoplastic known for its high strength, excellent wear resistance, good chemical stability, and toughness. It is widely used across industries for gears, bearings, bushings, automotive components, industrial parts, and more. Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications

POM

POM (Polyoxymethylene / Acetal) Engineering Material POM (polyoxymethylene), also known as acetal, is a high‑performance engineering thermoplastic valued for its rigidity, low friction, excellent wear resistance, and good dimensional stability. It is often used in precision mechanical parts that require durable, low‑maintenance performance.

HIPS

HIPS (High Impact Polystyrene) Material HIPS, or High Impact Polystyrene, is a modified polystyrene polymer enhanced with rubber modifiers (usually polybutadiene) to improve toughness and durability. The result is a rigid yet impact-resistant thermoplastic that retains good processability, making it popular in prototyping, manufacturing, and consumer products. HIPS combines the stiffness of polystyrene with improved

HDPE

HDPE (High-Density Polyethylene) Material High-Density Polyethylene (HDPE) is a thermoplastic polymer with high strength-to-density ratio, known for durability, chemical resistance, and ease of processing. As a semi-crystalline plastic, it offers excellent impact performance, low moisture uptake, and good machinability — making it a popular choice in industrial, chemical, packaging, and structural applications. It is great

ABS

ABS (Acrylonitrile Butadiene Styrene) Material ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent balance of strength, toughness, and processability. Because it combines rigidity from acrylonitrile and styrene with impact resistance from butadiene, ABS is commonly used in consumer products, enclosures, housings, and structural components.

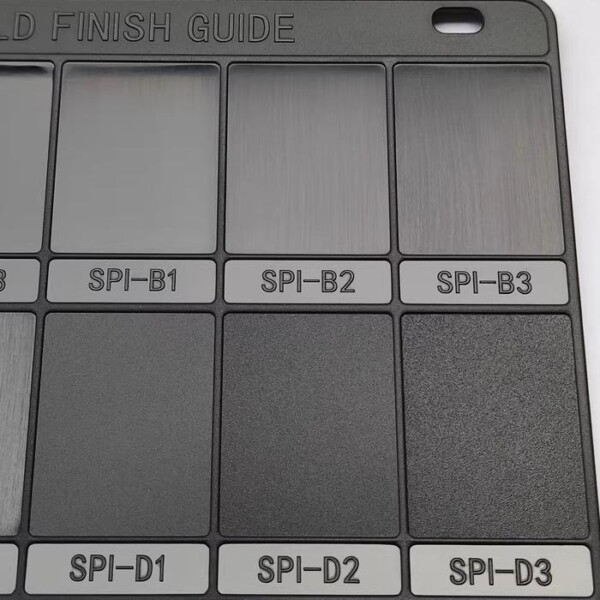

LSR Molding Surface Roughness Options

| SPI A | ||||

|---|---|---|---|---|

| Surface Roughness Ra(μm) | ||||

| SPI A1 | Ra0.012 – Ra0.025 | |||

| SPI A2 | Ra0.025 – Ra0.05 | |||

| SPI A3 | Ra0.05 – Ra0.10 | |||

| SPI B | ||

|---|---|---|

| Surface Roughness Ra(um) | ||

| SPl B1 | Ra0.05 -Ra0.10 | |

| SPl B2 | Ra0.10-Ra0.20 | |

| SPl B3 | Ra0.20-Ra0.28 | |

Surface Finish Options

Screen printing

Silk screen printing is a process that applies ink onto a product surface through a mesh screen. It’s widely used for logos, text, and patterns with strong adhesion and broad material compatibility.

Water transfer printing

Water transfer printing is a process that applies patterns to complex surfaces using a water-soluble film. It’s suitable for plastic, metal, and other materials, often used for decorative finishes.

Hot stamping

Hot stamping is a decorative process that uses heat and pressure to transfer metallic foil onto the surface of plastic parts, enhancing visual appeal and brand recognition.

Painting

A protective and aesthetic coating is applied to the surface, offering a smooth, uniform finish with customizable colors and textures. Silk screen printing is a process that applies ink onto a product surface through a mesh screen. It’s widely used for logos, text, and patterns with strong adhesion and broad material compatibility.

Industries Served by Injection Molding

Consumer Electronics

Prototyping and on-demand production of consumer electronics products.