Looking to test small-batch parts and gauge market response? Or ready to move into full-scale production? Choosing Horizon’s injection molding services is the right decision.

At Horizon, we use precision aluminum molds to quickly produce high-quality prototypes with short lead times—allowing you to validate manufacturability, functionality, and market acceptance faster than ever.

When it’s time for mass production, our full-scale injection molding solutions ensure a smooth, efficient transition from prototype to production, delivering consistency, reliability, and speed at every stage.

1000+

Customers Served

20+

Countries Served

1000000+

Parts Made

Why Horizon is Your Go-To Partner for Plastic Injection Molding?

With years of expertise in crafting high-quality injection-molded parts, Horizon clearly stands apart from the competition. We deliver true end-to-end injection molding solutions, managing every step from design to production to ensure unmatched quality and precision.

Here are four compelling reasons why Horizon should be your go-to partner for injection molding—no matter the part type or production volume.

1.Customized to Your Needs

While most injection molding companies focus solely on mass production, we do things differently. From low-volume prototyping to full-scale production of over a million parts, we provide flexible solutions that allow you to scale exactly as you need.

3.Reliable Quality

Our expert engineers kickstart your project with professional DFM analysis and precise mold making, then optimize injection molding parameters to ensure superior part quality.

2.Mold Manufacturing

We handle both mold fabrication and injection molding, allowing us to oversee the entire production process. This ensures consistent quality and makes it easy to scale up production whenever needed.

4.Unlimited Production Capacity

In addition to our in-house facilities, we collaborate with an extensive network of injection molding manufacturers. A large fleet of molding machines is always on standby, ready to efficiently handle your orders at any scale.

What is Plastic Injection Molding?

View Section

Plastic injection molding is a manufacturing process where molten plastic is injected into a mold under high pressure, then cooled to form the desired part. It precisely reproduces complex designs and is widely used in consumer electronics, automotive components, medical devices, and more.

Advantages of Plastic Injection Molding

How to Work With Us

Upload a CAD File

To start, simply select a manufacturingprocess and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we’ll send you designfor manufacturability(DFM) analysis andreal-time pricing.

Manufacturing Begins

Once you review your quote and placeyour order, we’ll start the manufacturingprocess. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allowsus to produce parts in as fast as 1 day.

Injection Molding Manufacturing Network

At Horizon Injection Molding Network, we combine technology, expertise, and precision to bring your plastic product ideas to life.

With over 60 state-of-the-art injection molding machines ranging from 80 to 800 tons, and a team of seasoned project managers, we deliver excellence on projects of any scale or complexity.

From rapid prototypes to full-scale production, we serve as your reliable manufacturing partner in China—offering global shipping, transparent communication, and technical guidance every step of the way.

Our goal is simple: to ensure every part meets your standards, every deadline is met, and every project exceeds expectations.

60+

Machines Set

2000+

Customers Worldwide

100+

Countries & Regions Served

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

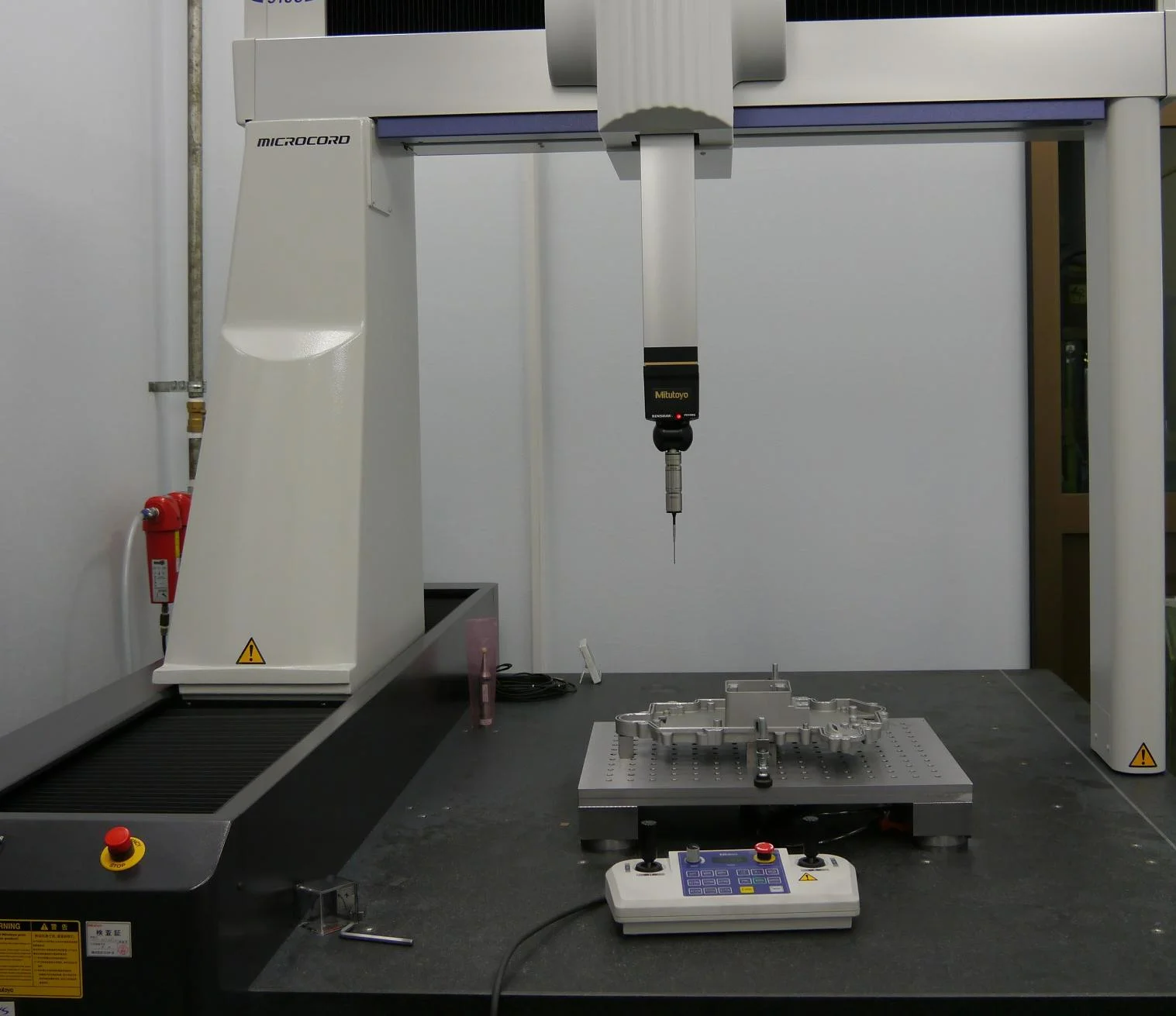

| 1 | Advanced Inspection Equipment | ||||

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

Plastic Injection Molding Materials

Our plastic injection molding service supports the production of parts using a wide variety of molding materials. These include rigid plastics such as ABS, flexible options like TPE, and blended materials such as PC-ABS. We can also source specialty materials and create custom material and pigment blends to meet your specific project requirements.

TPU

Thermoplastic Polyurethane (TPU) for CNC Machining HorizonRP offers high-quality Thermoplastic Polyurethane (TPU) material, known for its flexibility, durability, and resistance to abrasion and chemicals. Ideal for CNC machining applications, TPU is widely used across various industries, including automotive, medical, and consumer electronics.

PC+ABS

PC/ABS (Polycarbonate‑ABS Blend) Plastic Material PC+ABS is a blend-modified material that combines the advantages of both materials. It not only inherits the high impact resistance of PC but also the material strength of ABS, while improving its heat resistance. It is often used in electronic product casings, automotive interiors, consumer products, and more.

CPVC

CPVC (Chlorinated Polyvinyl Chloride) Plastic Material CPVC (Chlorinated Polyvinyl Chloride) is a modified form of PVC, with enhanced thermal stability, mechanical properties, and chemical resistance. These upgraded characteristics make CPVC an excellent choice for applications in high-temperature and corrosive environments where ordinary PVC would fail.

PC+GF

PC+GF(Glass‑Fiber Reinforced Polycarbonate) Material PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making

PEI

PEI (Polyetherimide) Engineering Material PEI (polyetherimide) is a high-performance thermoplastic known for excellent heat resistance, mechanical strength, and chemical stability. It is widely used in demanding applications across aerospace, electronics, medical, and industrial fields.

PTFE

PTFE Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer. It is frequently used in mechanical components requiring reduced friction and wear—such as bearings, gears, and piston rings—due to its non-stick properties, low friction characteristics, and self-lubricating capabilities. PTFE also exhibits excellent electrical insulation properties, making it highly suitable for applications like high-frequency cables,

LDPE

LDPE Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PP

PP Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

PET

PET PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PVC

PVC (Polyvinyl Chloride) Plastic Material Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as

PC

PC (Polycarbonate) Engineering Material PC (polycarbonate) is a versatile engineering plastic known for its high impact resistance, optical transparency, and good thermal stability. It combines toughness, heat resistance, and aesthetic clarity, making it suitable for a wide array of applications.

PMMA (Acrylic)

PMMA (Acrylic) Engineering Material Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical

PEEK

PEEK (Polyetheretherketone) Engineering Material PEEK (polyetheretherketone) is a premium thermoplastic widely recognized for its exceptional thermal stability, mechanical strength, chemical resistance, dimensional stability, and in many cases biocompatibility and electrical insulation. It is used in extreme environments like aerospace, medical implants, electronics, and semiconductor industries.

Nylon

Nylon (Polyamide) Engineering Material Nylon (polyamide) is a versatile engineering thermoplastic known for its high strength, excellent wear resistance, good chemical stability, and toughness. It is widely used across industries for gears, bearings, bushings, automotive components, industrial parts, and more. Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications

POM

POM (Polyoxymethylene / Acetal) Engineering Material POM (polyoxymethylene), also known as acetal, is a high‑performance engineering thermoplastic valued for its rigidity, low friction, excellent wear resistance, and good dimensional stability. It is often used in precision mechanical parts that require durable, low‑maintenance performance.

HIPS

HIPS (High Impact Polystyrene) Material HIPS, or High Impact Polystyrene, is a modified polystyrene polymer enhanced with rubber modifiers (usually polybutadiene) to improve toughness and durability. The result is a rigid yet impact-resistant thermoplastic that retains good processability, making it popular in prototyping, manufacturing, and consumer products. HIPS combines the stiffness of polystyrene with improved

HDPE

HDPE (High-Density Polyethylene) Material High-Density Polyethylene (HDPE) is a thermoplastic polymer with high strength-to-density ratio, known for durability, chemical resistance, and ease of processing. As a semi-crystalline plastic, it offers excellent impact performance, low moisture uptake, and good machinability — making it a popular choice in industrial, chemical, packaging, and structural applications. It is great

ABS

ABS (Acrylonitrile Butadiene Styrene) Material ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent balance of strength, toughness, and processability. Because it combines rigidity from acrylonitrile and styrene with impact resistance from butadiene, ABS is commonly used in consumer products, enclosures, housings, and structural components.

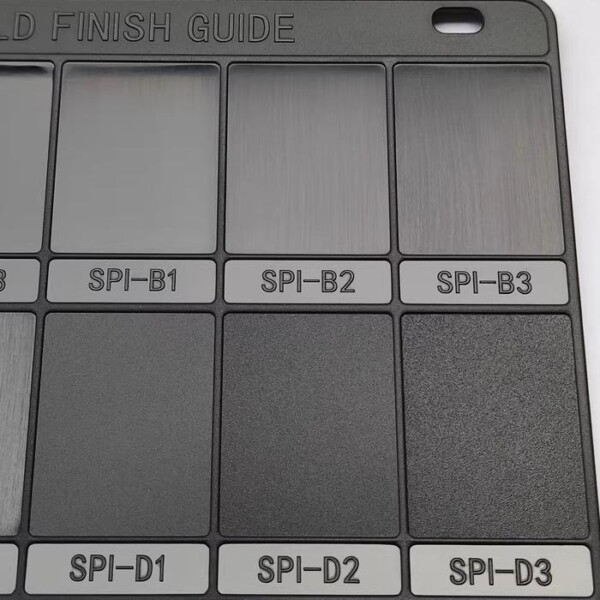

Injection Molding Surface Finish & Roughness Options

Roughness Options

Surface Finish Options

Screen printing

Silk screen printing is a process that applies ink onto a product surface through a mesh screen. It’s widely used for logos, text, and patterns with strong adhesion and broad material compatibility.

Water transfer printing

Water transfer printing is a process that applies patterns to complex surfaces using a water-soluble film. It’s suitable for plastic, metal, and other materials, often used for decorative finishes.

Hot stamping

Hot stamping is a decorative process that uses heat and pressure to transfer metallic foil onto the surface of plastic parts, enhancing visual appeal and brand recognition.

painting

A protective and aesthetic coating is applied to the surface, offering a smooth, uniform finish with customizable colors and textures. Silk screen printing is a process that applies ink onto a product surface through a mesh screen. It’s widely used for logos, text, and patterns with strong adhesion and broad material compatibility.

Customer Reviews

Industries Served by Injection Molding

Consumer Electronics

Prototyping and on-demand production of consumer electronics products