Laser Cutting Services with Horizon

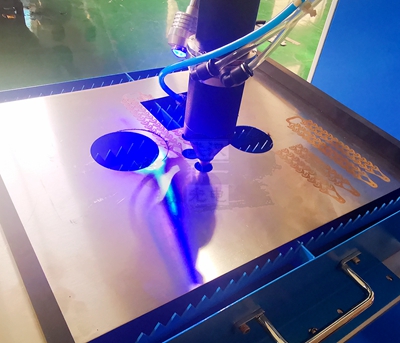

Laser cutting is a highly precise and efficient manufacturing process that uses a focused laser beam to cut through a wide range of materials. It is ideal for prototypes and low-volume production, delivering parts with tight tolerances, clean edges, and consistent quality. With fast turnaround and compatibility with metals, plastics, wood, and more, our laser cutting service ensures your designs move from concept to reality with speed and accuracy.

Choose the Right Laser Cutting Solution

Why Choose Our Sheet Metal Fabrication?

/01

Precision & Quality – Advanced laser cutting and forming equipment ensure tight tolerances and consistent accuracy

/02

Versatile Capabilities – From simple brackets to complex assemblies, we handle a wide range of sheet metal parts.

/03

Flexible Volumes – Prototyping, low-volume runs, or mass production – we scale to your needs.

/04

End-to-End Service – Cutting, bending, welding, surface finishing, and assembly – all in one place.

/05

Reliable Lead Times – Optimized workflows and experienced engineers ensure on-time delivery.

How to Work With Us

Upload a CAD File

To start, simply select a manufacturingprocess and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we’ll send you designfor manufacturability(DFM) analysis andreal-time pricing.

Manufacturing Begins

Once you review your quote and placeyour order, we’ll start the manufacturingprocess. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allowsus to produce parts in as fast as 1 day.

What is Laser Cutting?

Laser cutting is a high-precision, high-efficiency manufacturing process that can cut metals, plastics, wood, and other materials into custom shapes with smooth edges and accurate dimensions.

Horizon offers online custom laser cutting services for prototypes, small-batch, and large-scale production. Simply upload your 3D CAD design to receive an instant quote and seamlessly move from design to production. With advanced equipment, we handle complex designs with consistent precision and quality.

Horizon’s laser cutting service combines speed, accuracy, and convenience, providing an efficient solution for all your projects.

Laser Cutting Material

Metal

Aluminum, known for its light weight and corrosion resistance, plays a crucial role in the aerospace and automotive industries. Because of its highly reflective surface, fiber lasers are often used for cutting aluminum in combination with inert assist gases such as nitrogen. This approach reduces energy loss caused by reflection and ensures clean edges and smooth surface finishes.

Brass has high reflectivity and thermal conductivity, making laser energy absorption less efficient and cutting more difficult. Fiber lasers with high power density improve cutting stability, while nitrogen assistance prevents oxidation and produces smooth edges.

Copper shows even higher thermal conductivity and reflectivity, causing rapid heat dissipation and poor energy concentration. Using fiber lasers with specific wavelengths and nitrogen assistance reduces reflection losses and ensures clean, precise cuts.

Stainless steel, known for its strength and corrosion resistance, is widely used in automotive components, signage, and various industrial applications. Laser cutting machines enable efficient and precise processing of stainless steel, with a high energy density beam that minimizes the heat-affected zone, thereby preserving the material’s corrosion resistance and surface finish.

Low-carbon steel (carbon steel) is one of the most commonly laser-cut metals, widely used in structural components, machinery, and automotive parts. Laser cutting machines can efficiently and accurately process medium to thick carbon steel plates, offering high precision and speed. Oxygen is typically used as an assist gas to enhance cutting efficiency, while nitrogen provides cleaner, oxide-free edges.

Various steel alloys are also commonly laser-cut, including cold-rolled steel, hot-rolled steel, and galvanized steel. Cold-rolled steel offers a smooth surface suitable for high-precision cutting, while hot-rolled steel, with its oxide layer, typically requires higher power or oxygen assistance. Galvanized steel has a coated surface that may produce smoke and slag during cutting, so proper selection of assist gas is necessary to maintain clean edges.

Titanium is renowned for its high strength, corrosion resistance, and versatility, making it widely used in aerospace components and medical devices. During laser cutting, titanium tends to react with air and form an oxide layer. Therefore, controlled inert gases such as argon or nitrogen are typically used as assist gases to optimize cutting speed, improve energy absorption, and achieve smooth, oxidation-free edges.

Non-metallic

ABS material is suitable for parts that require durability and impact resistance, but when laser cutting, it is essential to pay attention to harmful fumes, cutting parameters, and safety precautions.

PMMA is highly favored for its transparency and high strength, as well as the clean, smooth edges achieved through laser cutting. It is widely used in signage, safety glass, and furniture. Proper ventilation is required during laser cutting to prevent harmful fumes.

Includes HDPE and LDPE; can be laser cut with CO₂ lasers, though slight discoloration and a wider kerf may occur.

Silicone is a heat-resistant, soft, and flexible material, suitable for seals, gaskets, and flexible components. When laser cutting silicone, precise contours and smooth edges can be achieved, but the process may produce fumes containing irritant gases, so proper ventilation and exhaust systems are required.

PP is known for its excellent chemical resistance and heat resistance. When laser cut, it produces clean, precise edges with minimal discoloration, though slight burrs may occur.

Laser cutting wood can achieve precise contours, smooth edges, and intricate pattern engraving, but the process may produce smoke and slight charring, so proper ventilation and exhaust systems are required.

Applications of Laser-Cut Parts

Laser cutting is a high-precision manufacturing process widely used in industries such as energy storage, computer electronics, robotics, and aerospace. It enables fast and accurate production of various components. Common applications include:

-

Flat patterns: Precise contouring for decorative or functional structural parts

-

Panels: Precision panels for electronic devices or mechanical enclosures

-

Gaskets: Seals or mechanical assembly components

-

Mounting plates: Supports or fixtures for components

-

Control panels: Fine machining for instruments and interface panels

Laser cutting in these applications not only improves accuracy and efficiency but also allows for the creation of complex structures and fine details, making it ideal for both mass production and customized parts.

Sheet Metal Fabrication resources

Avoid When Designing Sheet Metal Parts

What is Sheet Metal Fabrication?

Sheet metal fabrication is a cornerstone of modern manufacturing. From the sleek body of a car to the sturdy casing of electronics, and even the structural components in buildings, countless everyday items rely on precisely fabricated sheet metal parts.

Guide to Sheet Metal Materials