Punching – Fast & Cost-Effective Sheet Metal Processing

Punching is a high-speed sheet metal process that uses a punch press to create holes, cutouts, and special shapes with great accuracy. It is widely used for functional and decorative features in prototypes and low-to-medium volume production. With punching, complex patterns can be achieved in seconds, offering:

Whether you need simple perforations or complex geometries, our punching service ensures high-quality results with fast turnaround.

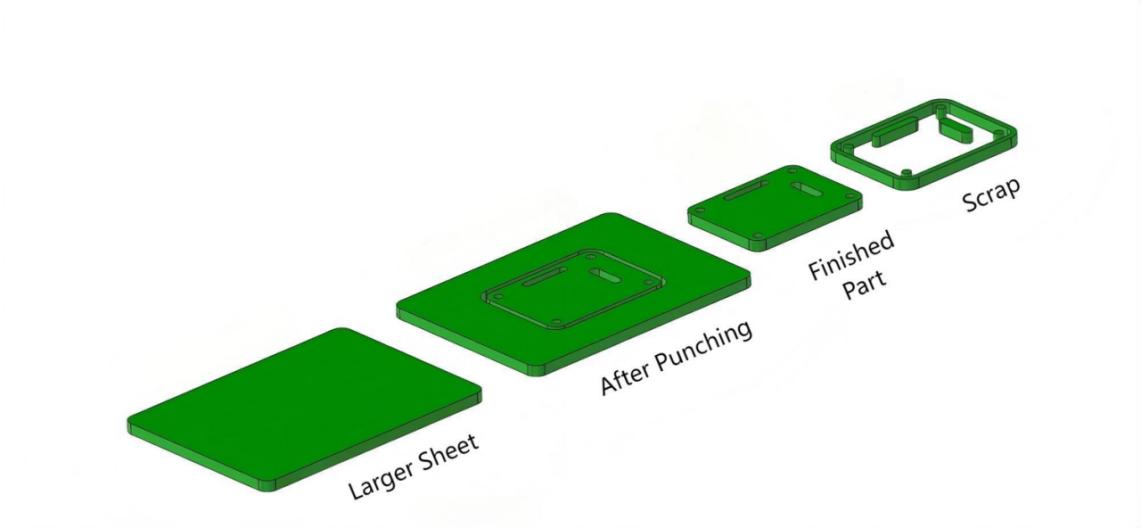

How Punching works?

Punching is a metal forming process that uses a punch press to force a tool (called a punch) through a sheet of metal to create a hole or shape. The punched-out piece is usually scrap (called a slug), while the remaining sheet becomes the part.

How to Work With Us

Upload a CAD File

To start, simply select a manufacturing process and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we’ll send you design for manufacturability(DFM) analysis andreal-time pricing.

Manufacturing Begins

Once you review your quote and place your order, we’ll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allows us to produce parts in as fast as 1 day.

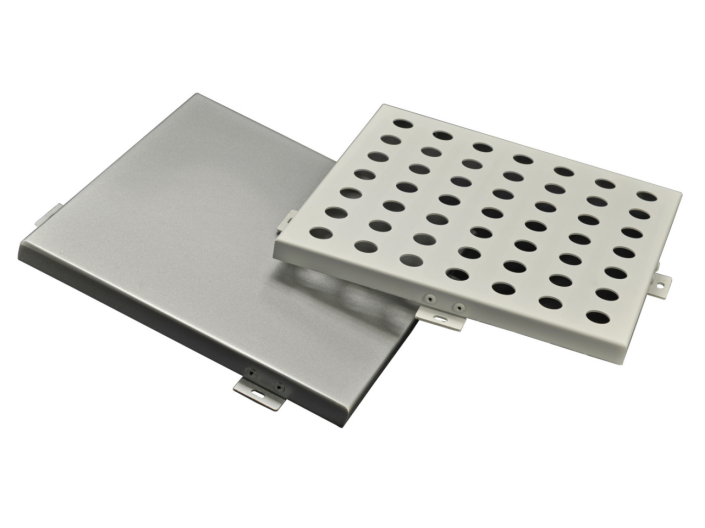

Punching Material

Aluminum Sheet Metal Fabrication Service is your gateway to precision-crafted, durable components. Marrying cutting-edge technology with seasoned craftsmanship, we transform raw aluminum sheets into masterpieces, ensuring reliability and aesthetic finesse in every creation.

- Subtypes: 5052, 5083, 6061, 6082

Our Copper Sheet Metal Fabrication Service transforms quality copper sheets into durable components. Trust us for dependable solutions tailored to diverse needs.

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.

- Subtypes: 101, C110

Brass Sheet Metal Fabrication Services, focusing on precision and durability. Using quality brass sheets, we ensure reliable and long-lasting products for various applications.

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and is the best choice for low-friction applications.

- Subtypes: C360, H59, H62

Our stainless steel sheet metal services offer corrosion-resistant components that combine strength and polish, ideal for functionality and aesthetics.

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.

- Subtypes: 301, 304, 316

In order to achieve strong and durable effect, the steel plate metal parts use high quality steel plate to make precision parts to ensure the strength and quality of each part.

It is mechanically strong, ductile, resistant to wear and fatigue, and robust. In addition to carbon, other alloying elements can be added depending on the desired mechanical and physical properties.

1018, SPCC

Punching Design Guide

The design of stamped sheet metal parts is often complex. To help integrate them smoothly into your next project, the following outlines key manufacturability considerations to keep in mind during the design process. These guidelines will help reduce project costs, improve production efficiency, and ensure consistent, high-quality parts.

- All forming features should be oriented consistently. Designs that incorporate both upward and downward forming features are prone to quality issues.

- The distance between holes should generally be 1.5 times the material thickness. For soft materials or when using a multi-hole (cluster) punch, the hole spacing can be reduced to 1.2 times the material thickness. However, when using a single-hole punch, a larger spacing is required to ensure consistent hole quality.

- The minimum hole diameter should be designed as 1.2 times the material thickness.

- The number of unique punch features with different sizes or shapes in the design should be minimized. Using features of the same size can reduce mold setup and adjustment time, potentially lower tooling costs, and improve both production efficiency and the consistency of part quality.

- The tolerances for stamped features should be maintained within ±0.127 mm. It is important to note that the dimensional tolerances in the flat state differ from those in the formed state. Therefore, design considerations should account for both conditions to ensure part assembly accuracy and manufacturability.

Assembly service

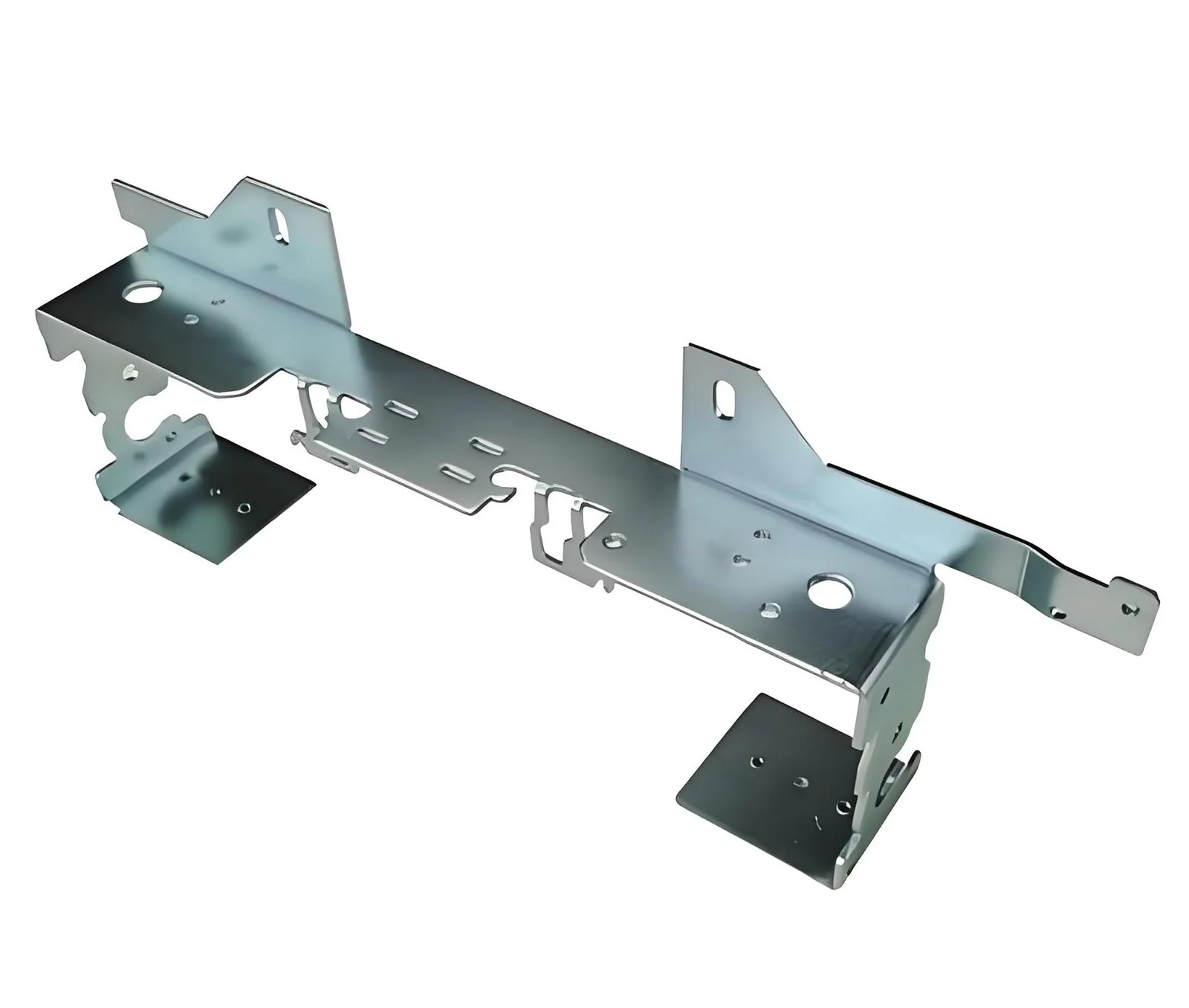

Although sheet metal parts with stamped features can be used as independent components, in practical industrial applications they are more commonly integrated into assemblies, subassemblies, or welded units to form fully functional components. To streamline the implementation of your project, we offer the following professional assembly services, ensuring that delivered components can be immediately used in subsequent operations:

-

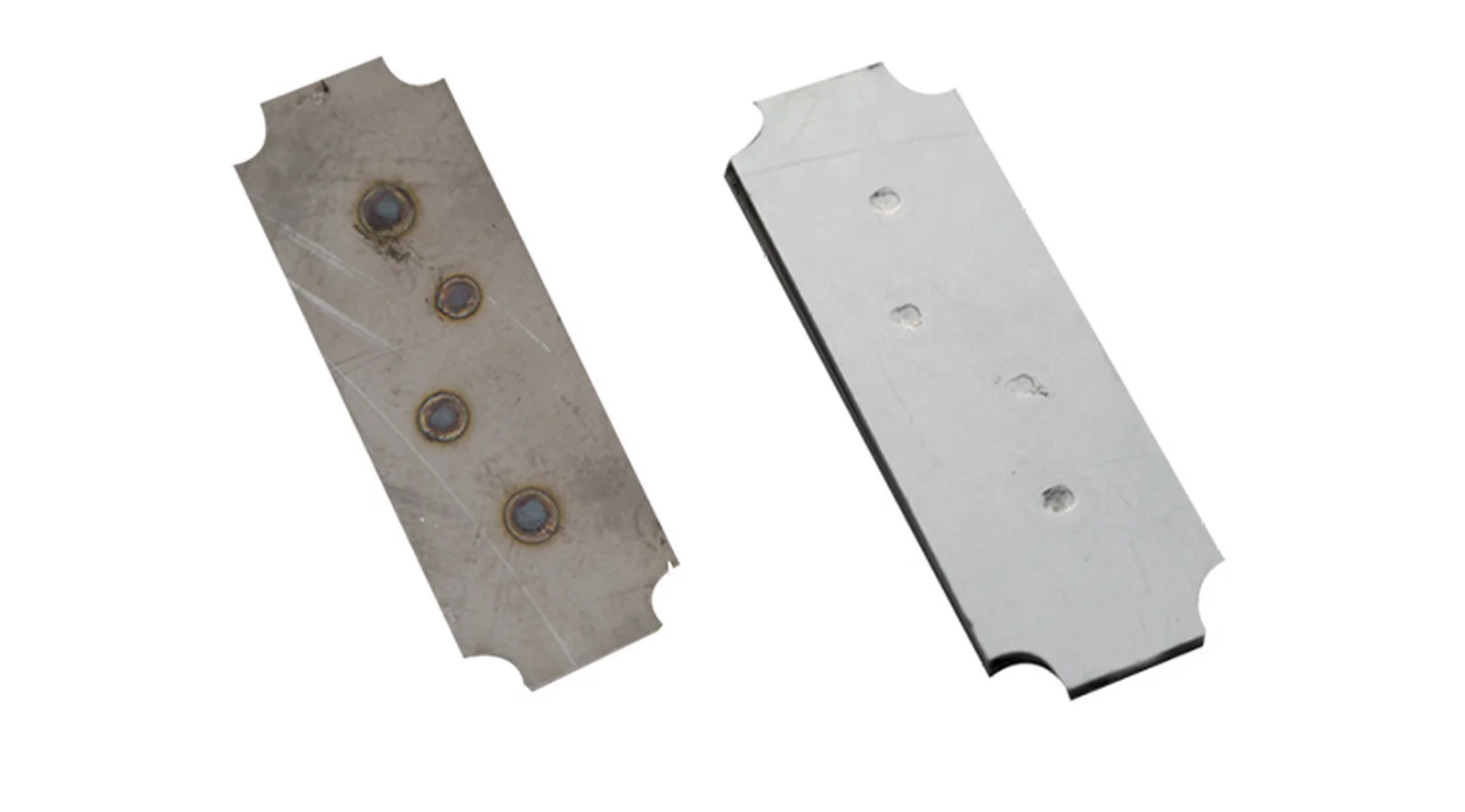

Precise hardware installation

-

Welding services

-

Riveted assembly

The assembly process typically adds 1–3 days to the base production cycle. The exact duration will depend on factors such as the number of components, assembly complexity (e.g., multi-step operations, high-precision positioning requirements), and other project-specific details. We will confirm the precise timeline with you in advance based on the specifics of your project.

Surface Finish and Post-Processing Options

As machined

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Sheet Metal Fabrication resources

Avoid When Designing Sheet Metal Parts

Sheet metal components are widely used in industries such as electronics, automotive, machinery manufacturing, and household appliances. Although they may seem simple, designing sheet metal parts that are both reliable and cost-effective is far from easy.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a cornerstone of modern manufacturing. From the sleek body of a car to the sturdy casing of electronics, and even the structural components in buildings, countless everyday items rely on precisely fabricated sheet metal parts.

Guide to Sheet Metal Materials

Through this article, you will gain a clear understanding of the most widely used sheet metal materials and how to evaluate them for your specific needs. Instead of getting lost in technical jargon, you’ll discover which properties really matter—strength, corrosion resistance, weight, cost, and appearance—and how they influence your project outcomes.