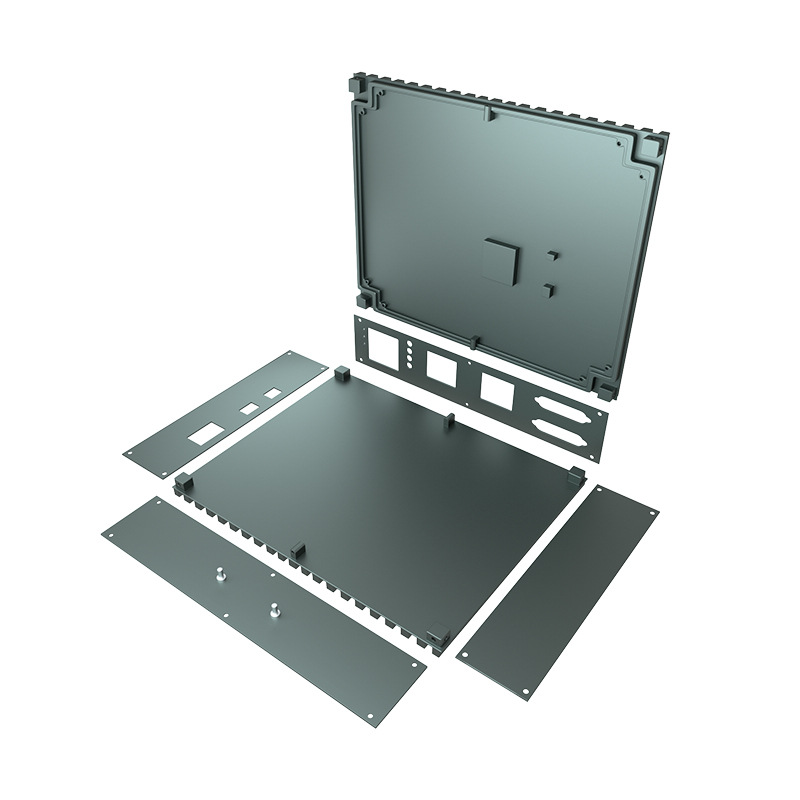

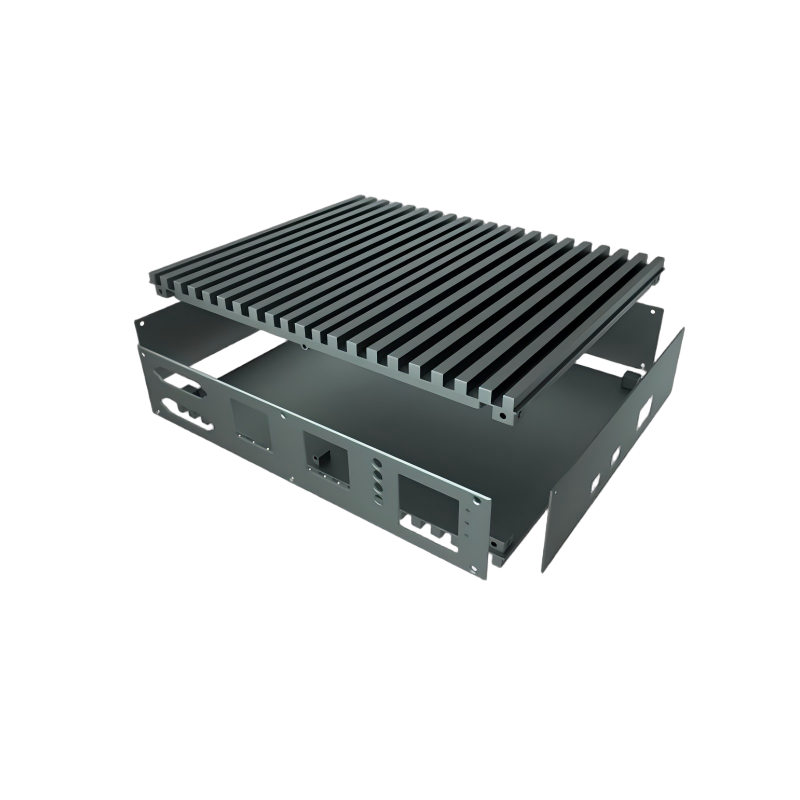

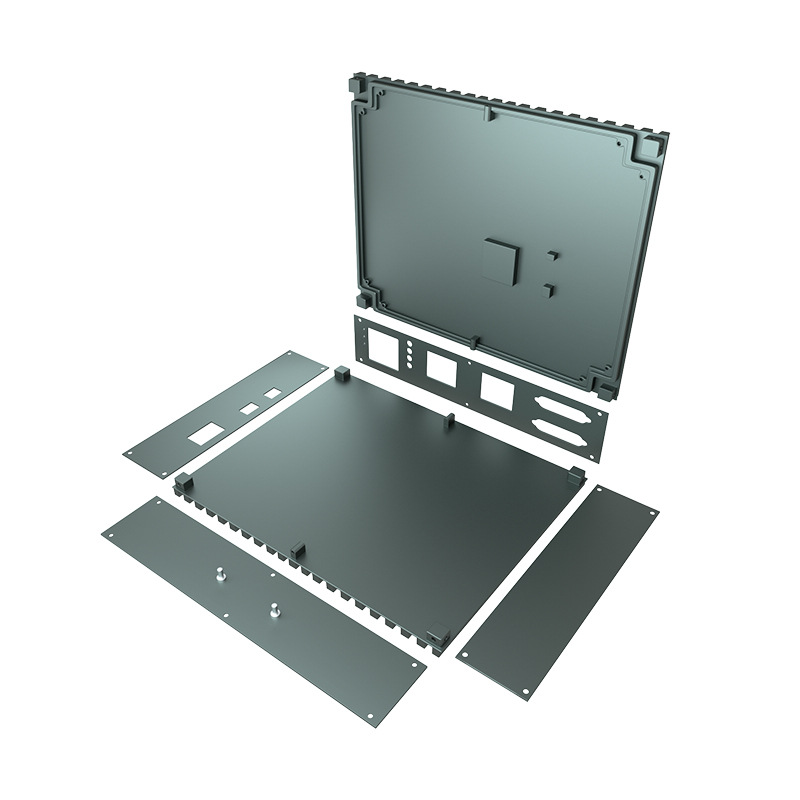

What Are Fabricated Assemblies?

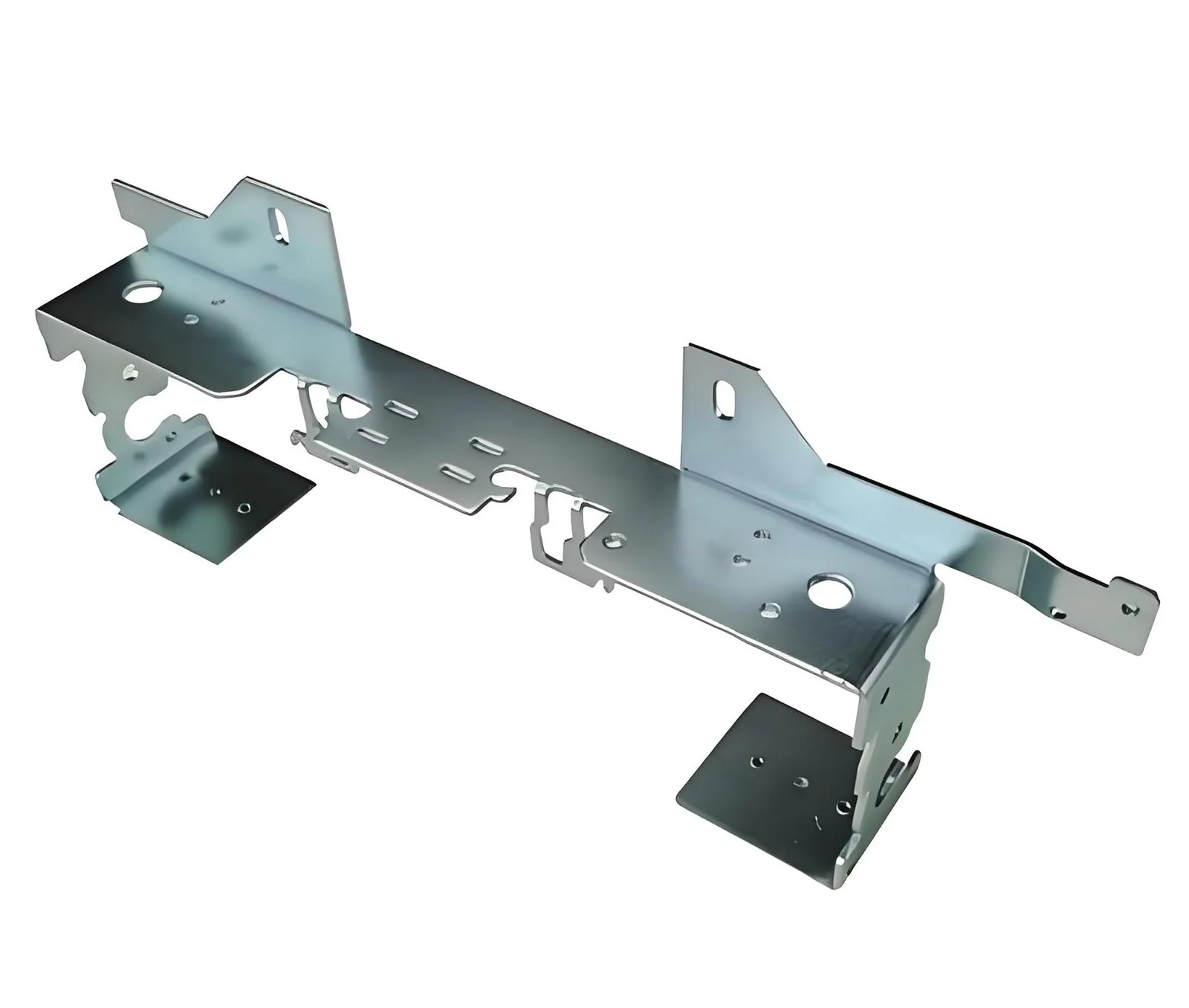

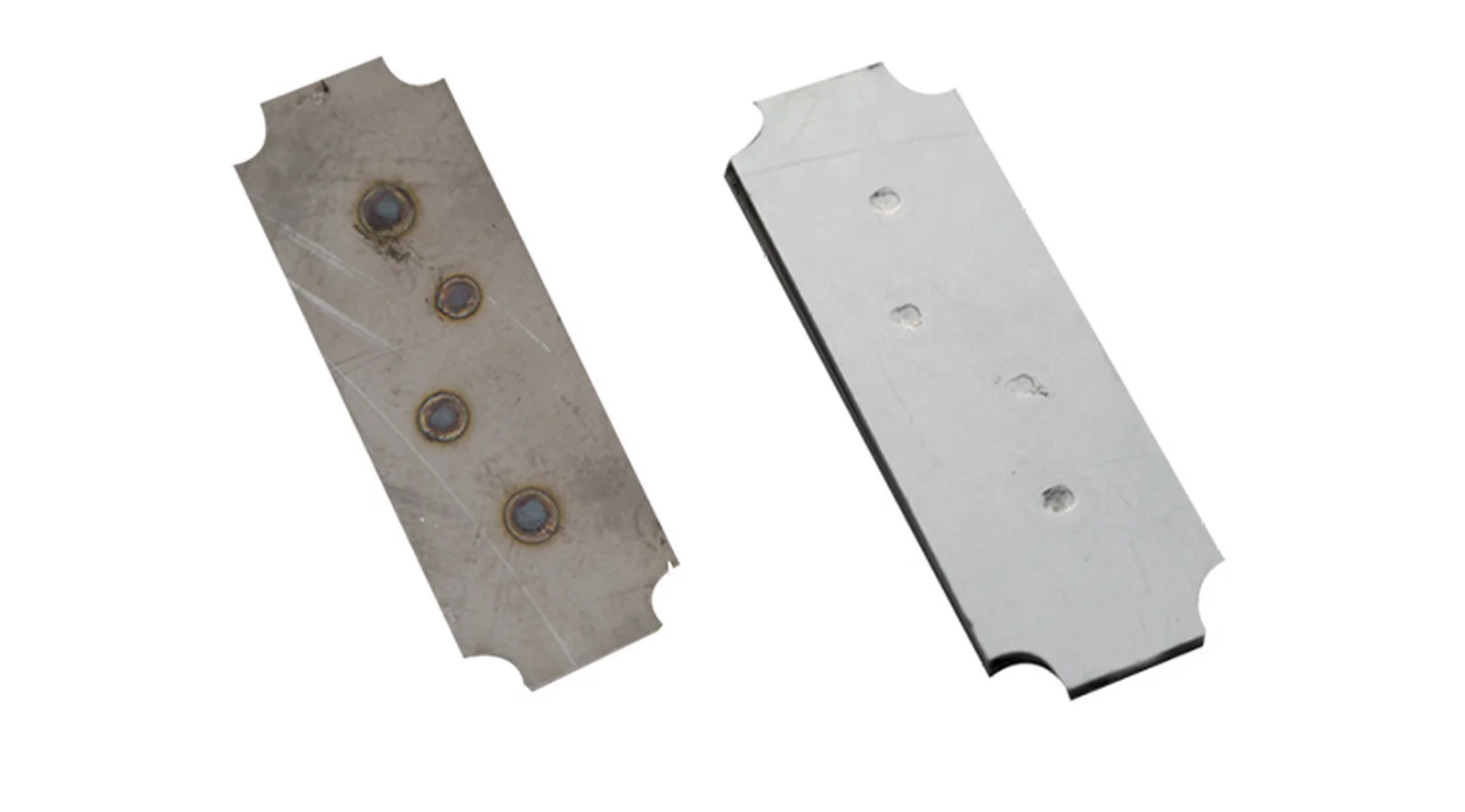

Fabricated assemblies are more than just individual parts — they are complete, ready-to-use solutions created by combining multiple fabricated or machined components. Using processes such as welding, riveting, fastening, and surface finishing, these assemblies transform separate parts into functional, durable units.

For customers, fabricated assemblies mean:

Simplified Supply Chain – Instead of sourcing and managing multiple vendors, you receive fully assembled products directly from one reliable partner.

Time & Cost Efficiency – Reduced logistics, faster turnaround, and lower overhead costs.

Consistent Quality – Every component is manufactured, finished, and assembled under strict quality controls.

Application-Ready Solutions – Deliveries come as finished assemblies, saving you additional labor and preparation.

Why Choose Us?

One-Stop Service

From custom components to complete assemblies, we handle every step in-house. This eliminates the hassle of coordinating multiple suppliers and ensures seamless integration.

High Precision & Reliability

Every assembly is built with strict tolerances and robust connections, guaranteeing long-term performance, safety, and consistency.

Flexible Production Volumes

Whether you need prototypes, low-volume runs, or scalable production, we adapt to your project needs without compromising quality.

Cost & Lead Time Savings

By streamlining fabrication and assembly under one roof, we shorten production cycles and reduce overall costs, helping you reach the market faster.

Sheet metal materials

Aluminum Sheet Metal Fabrication Service is your gateway to precision-crafted, durable components. Marrying cutting-edge technology with seasoned craftsmanship, we transform raw aluminum sheets into masterpieces, ensuring reliability and aesthetic finesse in every creation.

- Subtypes: 5052, 5083, 6061, 6082

Our Copper Sheet Metal Fabrication Service transforms quality copper sheets into durable components. Trust us for dependable solutions tailored to diverse needs.

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.

- Subtypes: 101, C110

Brass Sheet Metal Fabrication Services, focusing on precision and durability. Using quality brass sheets, we ensure reliable and long-lasting products for various applications.

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and is the best choice for low-friction applications.

- Subtypes: C360, H59, H62

Our stainless steel sheet metal services offer corrosion-resistant components that combine strength and polish, ideal for functionality and aesthetics.

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.

- Subtypes: 301, 304, 316

In order to achieve strong and durable effect, the steel plate metal parts use high quality steel plate to make precision parts to ensure the strength and quality of each part.

It is mechanically strong, ductile, resistant to wear and fatigue, and robust. In addition to carbon, other alloying elements can be added depending on the desired mechanical and physical properties.

1018, SPCC

Surface Finish and Post-Processing Options

As machined

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Fabricated Assemblies