Innovative Companies We Support

Horizon’s Aluminum Extrusion Services

At Horizon, we go beyond standard extrusion. With trusted partners, we provide small-batch aluminum and plastic extrusion services, perfectly suited for prototyping and low-volume production.

Our partners operate 30+ extrusion presses of varying tonnage, all ISO 9001:2015 certified, capable of producing complex aluminum profiles with precision.

Unlike most suppliers that only offer extrusion, Horizon takes it further:

We are equipped with a wide range of high-precision CNC machines for secondary machining, delivering a true one-stop solution—from extrusion to finished product. This means faster development, smoother production, and peace of mind for our customers.

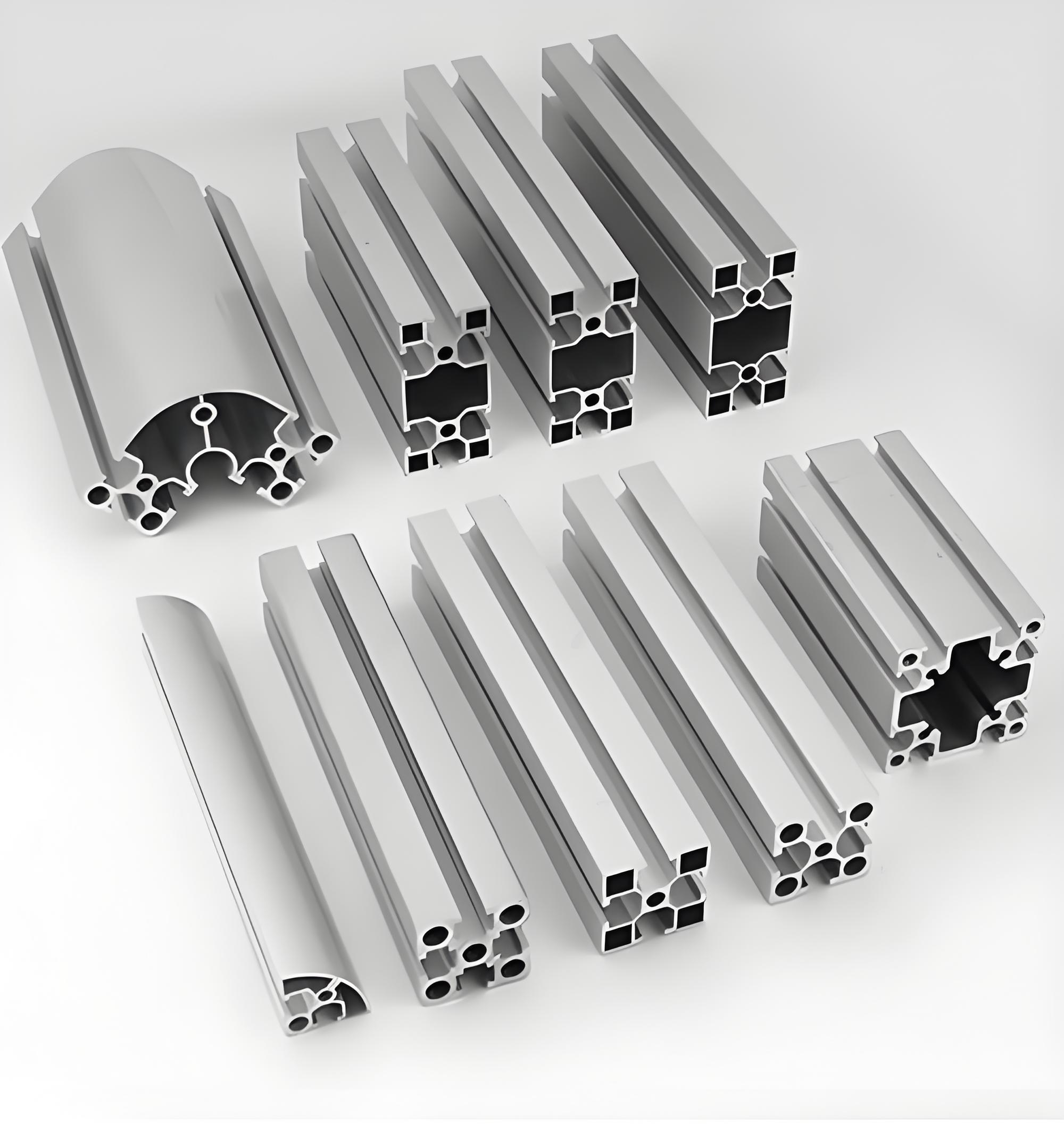

Aluminum Extrusion

Aluminum extrusion is a process that shapes aluminum into specific profiles. The aluminum is heated and forced through a die, producing continuous profiles with uniform cross-sections. It can create a wide variety of complex shapes, with lengths cut to specification, and is easily adaptable for secondary processing such as cutting, drilling, or CNC machining. Commonly used alloys include 6061 and 6063.

Plastic Extrusion

Thermoplastics come in many varieties, with common examples including polystyrene, nylon, polypropylene, and polyethylene. By heating and melting the material, then extruding it through molds, products with various cross-sectional shapes can be produced.

How to Work With Us

Upload a CAD File

To start, simply select a manufacturingprocess and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we’ll send you designfor manufacturability(DFM) analysis andreal-time pricing.

Manufacturing Begins

Once you review your quote and placeyour order, we’ll start the manufacturingprocess. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allowsus to produce parts in as fast as 1 day.

Why choose Horizon for custom extrusion services?

Horizon

Other Enterprise

Materials for Custom Aluminum Extrusion

Our standard alloy range offers a variety of strengths, corrosion resistance, and machinability, making it widely used in the construction, automotive, and electronics industries. Below are the materials we commonly use.

High-strength aluminum alloys offer excellent corrosion resistance and good machinability, making them ideal for structural components, mechanical parts, and automotive applications that demand high strength. They are also easy to weld and fasten, facilitating subsequent processing and assembly.

High-strength aluminum alloys offer excellent corrosion resistance and good machinability, making them ideal for structural components, mechanical parts, and automotive applications that demand high strength. They are also easy to weld and fasten, facilitating subsequent processing and assembly.

AL6063 exhibits excellent heat dissipation, moderate strength, and good corrosion resistance, with outstanding anodizing performance. It is widely used in LED heat sinks, electronic device enclosures, air conditioner condenser fins, and architectural profiles such as doors and windows.

AL6063 exhibits excellent heat dissipation, moderate strength, and good corrosion resistance, with outstanding anodizing performance. It is widely used in LED heat sinks, electronic device enclosures, air conditioner condenser fins, and architectural profiles such as doors and windows.

Finishing Options for Aluminum Extrusions

The aluminum extrusion process is widely used for the mass production of non-aesthetic components, where surface treatment requirements may not be high. However, custom aluminum extrusions can also be used to manufacture high-value products, which can significantly enhance both appearance and functionality through surface treatments such as anodizing, laser engraving, and painting.

Surface treatment processes suitable for aluminum extrusions include:

Anodizing

An oxide layer is formed on the aluminum surface through an electrochemical process, enhancing corrosion and wear resistance, while allowing coloring to improve aesthetic appeal.

It is suitable for components requiring high corrosion resistance and decorative applications, such as electronic enclosures and architectural profiles.

Sandblasting

High-speed sandblasting is used to clean and roughen the surface, producing a uniform matte finish. It is suitable for decorative components and enhances coating adhesion, often used in combination with anodizing.

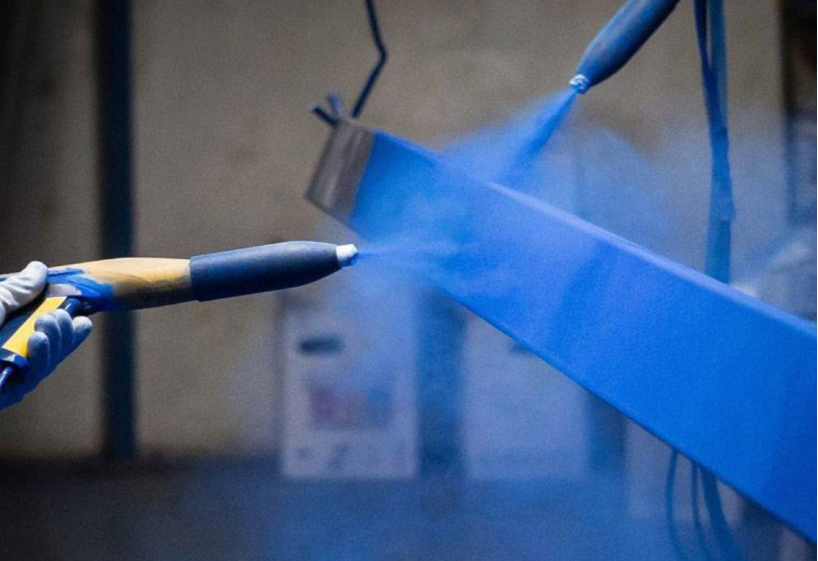

Powder Coating

Powder coating involves spraying powdered paint onto the aluminum surface and then baking it to form a durable, corrosion-resistant, colored protective layer. It is suitable for outdoor structures, architectural profiles, and appliance enclosures.

Painting

Liquid painting involves applying a coat of liquid paint, allowing for a variety of colors and gloss finishes. It is suitable for aluminum components that require high aesthetic appeal or specific brand colors.

Brushing

Brushing or matting uses mechanical methods to create fine linear textures or a matte finish on the surface, enhancing tactile and visual appeal. It is suitable for decorative components, such as furniture and electronic device panels.

Laser Engraving

Laser engraving or etching uses a laser to inscribe text, patterns, or logos on the surface with high precision and permanent results. It is used for brand logos, decorative designs, or functional markings.

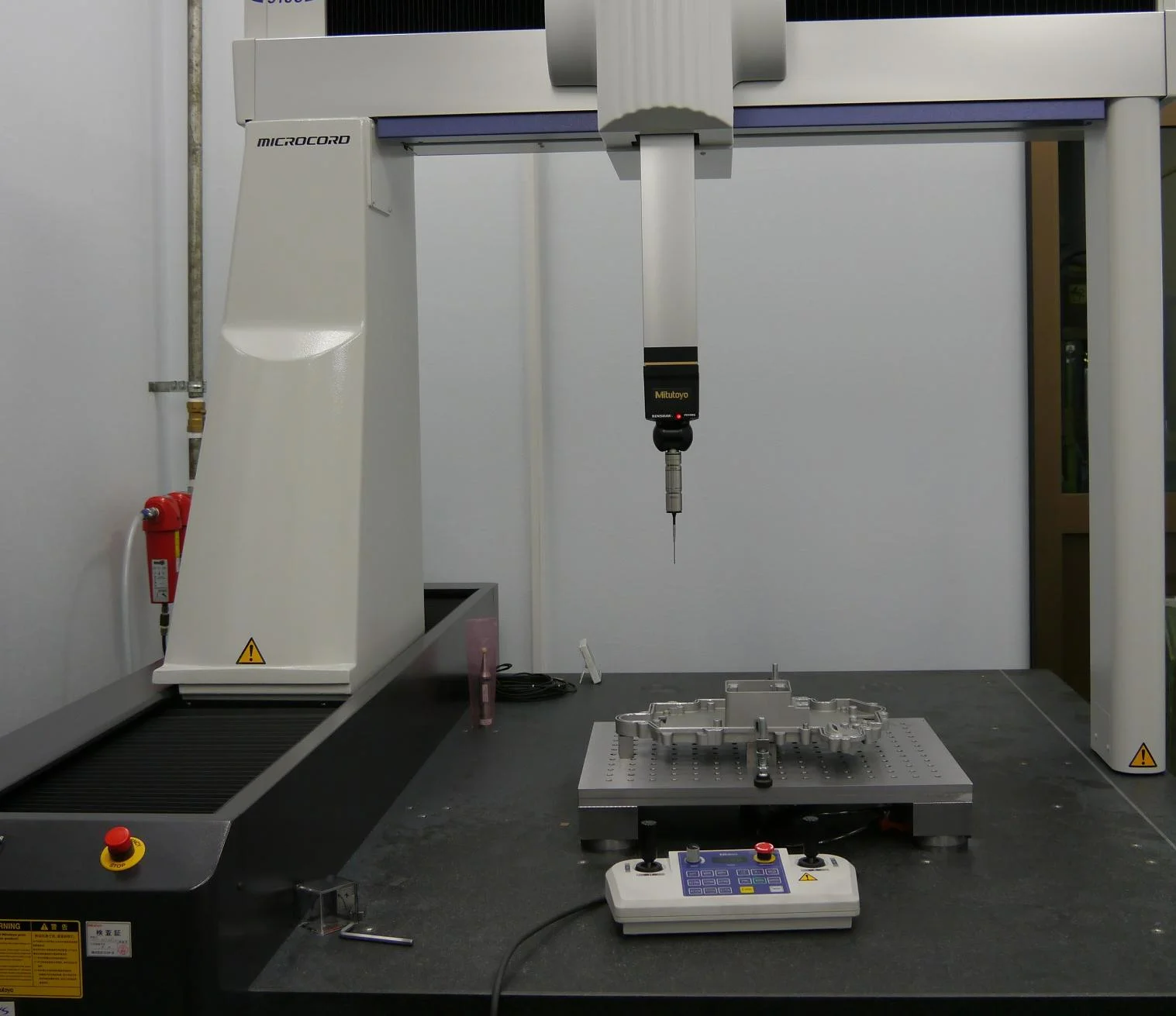

Quality Assurance

Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality.

What is Aluminum Extrusion?

Horizon is an ISO 9001:2015 certified manufacturer offering high-precision, high-quality CNC machining services for both metal and plastic parts. Our capabilities include milling and turning services: Milling equipment: 3-axis, 4-axis, and 5-axis precision CNC machining Turning equipment: automated lathes and turn-mill centers Auxiliary processes: EDM (Electrical Discharge Machining) All processes can achieve strict tolerances of ±0.01 mm. In addition, we specialize in custom CNC machining, from rapid prototyping and small-batch trial production to full-scale mass production. We also offer a wide range of surface finishing options — including plating, anodizing, and passivation — with neutral salt spray resistance of over 720 hours, ensuring your parts are not only dimensionally precise but also visually flawless. Whether you are an individual, a startup, or a global enterprise, Horizon is your trusted partner for on-demand custom CNC machining. Get your instant quote today!

Applications of Aluminum Extrusion

In the field of construction and architectural decoration, aluminum profiles are widely used in many applications, such as aluminum alloy ladders, window frames, curtain wall profiles, and balcony railings.

In the power industry, extruded aluminum alloys are commonly used in cable trays, busway housings, and heat sinks.

Extruded aluminum profiles can be used in the manufacture of machine tool guide rails, conveyor supports, and automation equipment frames.

Extruded aluminum alloys are commonly used in the manufacture of automotive chassis components, deck supports, and similar parts.

Extruded aluminum alloys are commonly used in the support structures of solar panels, the frames of battery packs, and the enclosures of energy storage cabinets.

Extrusion Products Showcase