What you can expect from us?

Surface finishing encompasses a range of professional processes designed to enhance the surface of your products, giving them the desired appearance and feel while improving key properties such as adhesion, solderability, corrosion resistance, hardness, and conductivity. This not only extends the product’s lifespan but also increases its overall value and market competitiveness.

At Horizon, we offer comprehensive surface finishing services for all components and parts, regardless of the manufacturing method used. Our experienced and skilled finishing team pays attention to every detail, ensuring exceptional quality from prototype to full-scale production.

By choosing Horizon, you will benefit from:

- A wide range of finishing techniques to meet diverse material and functional requirements

- Precise control to ensure uniform and

- consistent surfaces on every component

- Fast turnaround with timely and accurate quotes and services

- Reliable quality that delivers perfection in appearance, feel, and performance

Whether for prototypes or large-scale production, we bring your products to life with flawless surface finishes that truly reflect your design vision. Contact our customer service team today to experience high-quality surface finishing.

Surface Finish Options

Description

Pictorial View

Applicable Materials

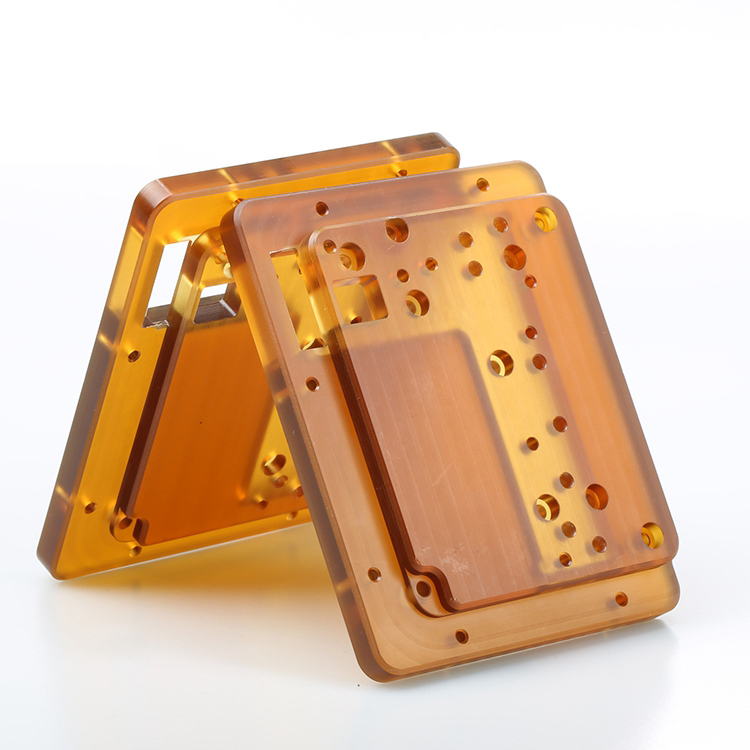

As machined

Parts are delivered with the original machined surface, typically around Ra 3.2 μm, with sharp edges deburred and chamfered.

Metals and Plastics

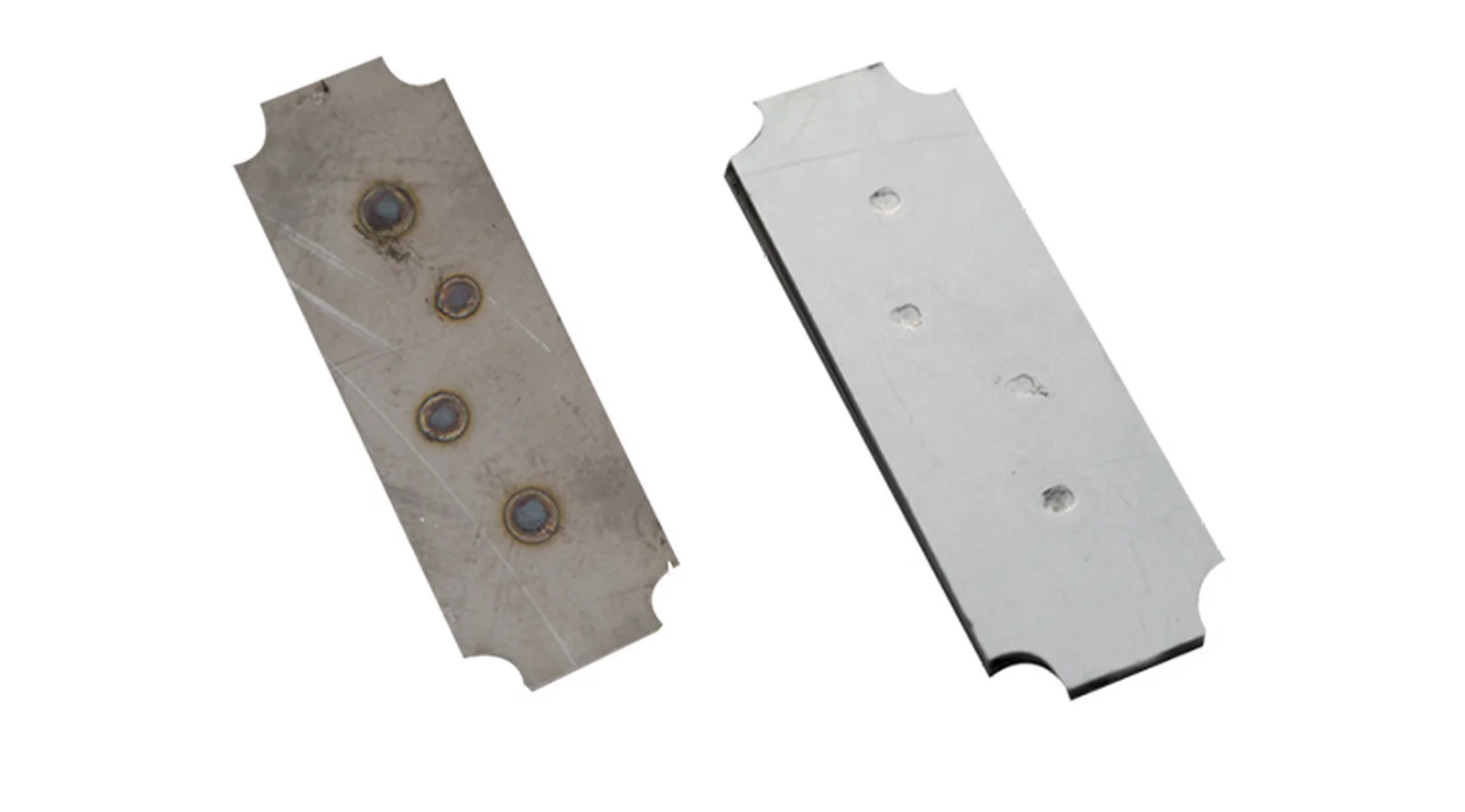

Deburring

Deburring is the process of removing sharp edges, burrs, and residual chips left behind after machining. It improves safety, ensures smoother assembly, and enhances the overall quality of the part.

Metals and Plastics

Sandblasting

Sandblasting produces a matte texture, removing all machining marks. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Metals and Plastics

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Metals and Plastics

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Metals and Plastics

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Metals

Laser Engraving

Laser engraving uses a focused laser beam to etch permanent markings on the surface of a part. It is ideal for logos, serial numbers, QR codes, and other precise identifiers, offering high accuracy and durability without affecting the part’s integrity.

Metals and Plastics

Screen Printing

Screen printing applies ink onto the part surface through a fine mesh stencil. This process allows for colorful, detailed graphics or labels, making it suitable for branding, functional markings, and decorative finishes on flat or slightly curved surfaces.

Metals and Plastics

Painting

Painting adds a protective and aesthetic layer to the part surface. With a wide range of color and finish options—such as gloss, matte, or metallic—painting enhances the appearance while providing resistance against wear, moisture, and corrosion.

Metals and Plastics

Powder Coating

Powder coating uses electrostatic application of dry powder, which is then cured under heat to form a durable finish. It offers superior hardness, chemical resistance, and environmental durability compared to traditional painting, making it ideal for functional and decorative purposes.

Metals

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Aluminum

Black Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Steel,Stainless Steel,Cast Iron

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Aluminum

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Steel,Stainless Steel,Copper,Aluminum,Zinc Alloys,Plastics (mainly ABS Plastics)

Chromate Coating

A chemical surface treatment for metals that forms a protective film through a chromium-based reaction, enhancing corrosion resistance and coating adhesion.

Aluminum

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Steel, Stainless Steel, Copper, Aluminum

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Stainless Steel,Aluminum

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Metals