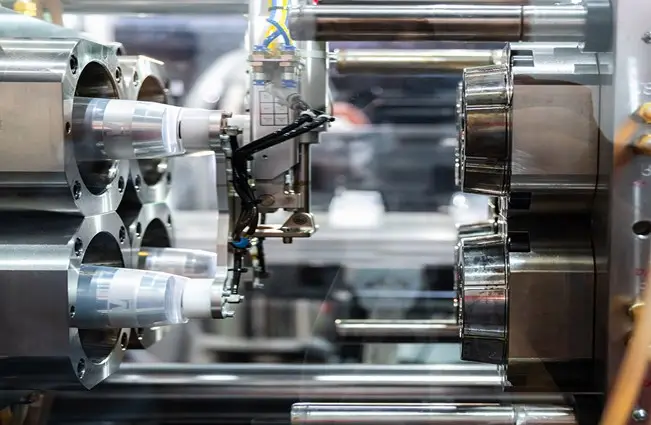

Aerospace Component Manufacturing

for Prototyping and Production

Specializing in the manufacturing of custom aerospace prototypes and mass production parts, we deliver cost-effective services through an on-demand production model, helping to accelerate time-to-market, reduce costs, and enhance efficiency.

Why manufacture aerospace parts with Horizon?

At Horizon, our reliable rapid prototyping services support customers across all sectors of the aerospace industry. We specialize in quickly producing high-precision aerospace prototypes, while our advanced production systems can deliver small, medium, or large-scale quantities with consistent quality and cost-effective results.

We Help From ——

Prototyping to Production

01 Prototyping

Bring your ideas to life with high-quality prototypes tailored to your product’s design and requirements. At this stage, we help you create and refine prototypes for testing, enabling critical material and design iterations. Depending on your goals and budget, we use cost-effective materials and processes to produce parts that closely resemble the final product — helping you validate functionality, fit, and overall design before full-scale production.

02 Engineering Validation and Testing

Easily and efficiently refine precise, functional prototypes to ensure all performance requirements are met. Our prototypes are designed to reveal potential design risks early, allowing you to address and mitigate them before production. Multiple iterations may be carried out to confirm that each prototype meets every functional and performance benchmark.

03 Design Validation and Testing

Effectively validate part functionality, performance, and appearance through a wide selection of materials and surface finishing options. This stage allows you to evaluate the final look, feel, and performance of your aerospace components before full-scale production. With Horizon’s extensive capabilities in mechanical design, materials, and finishes, we ensure every detail meets your specific requirements.

04 Production Validation and Testing

Prepare your design for full-scale manufacturing with production-grade processes and advanced quality assurance. During this stage, we help you validate your design under real production conditions, gather feedback, and make final adjustments to ensure efficient, high-quality manufacturing. Our DVT support ensures a seamless transition from prototype to production.

05 Mass Production

Seamlessly transition from product testing to full-scale manufacturing of end-use parts. With precise quality standards and rapid delivery, we ensure your final products meet the highest performance and reliability expectations. Backed by advanced manufacturing technologies and engineering expertise, our team manages the entire production process—maintaining high yield, consistent quality, and optimized cost efficiency.

Manufacturing Services for Aerospace Products

Materials for Aerospace Components

We provide an extensive selection of materials compatible with all our manufacturing processes. Below are some of the most popular options used in aerospace applications.

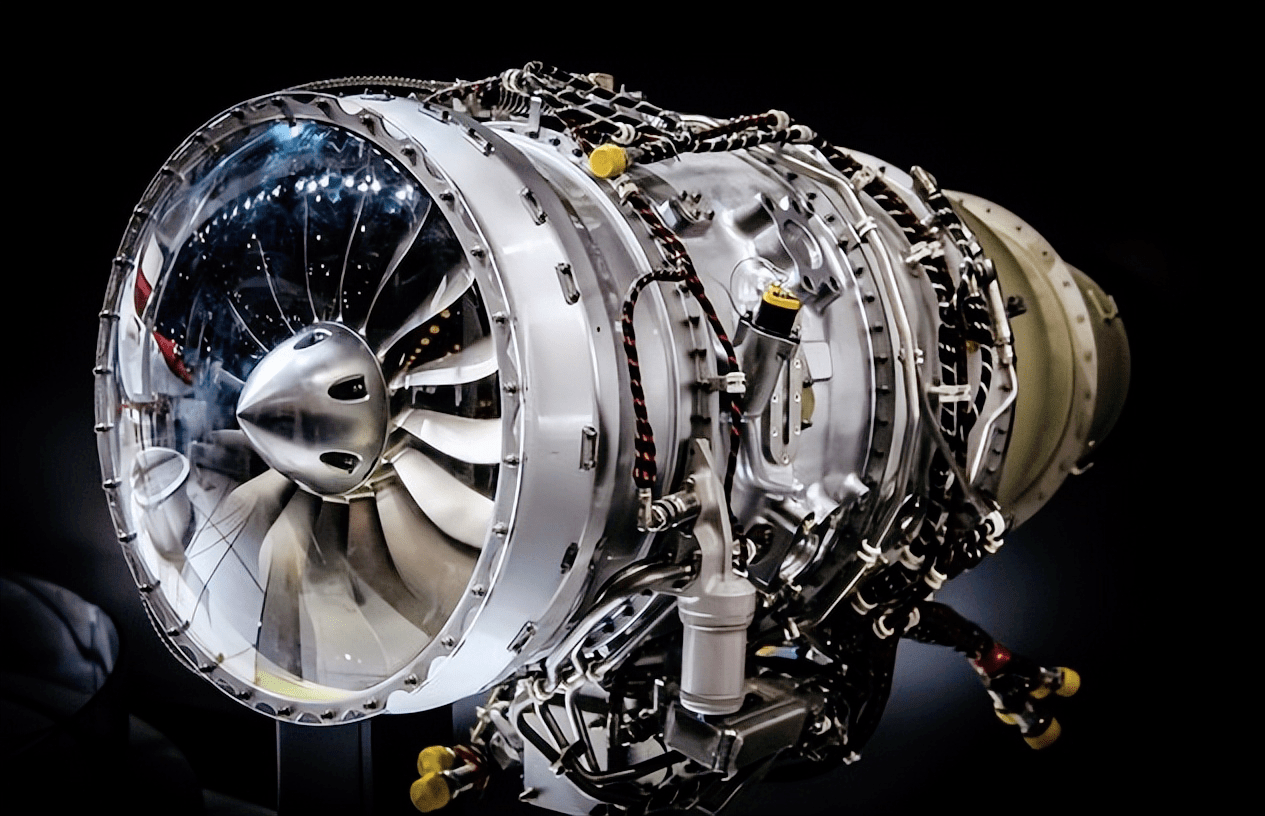

Inconel

Inconel is a high-performance nickel-chromium superalloy known for its exceptional strength, oxidation resistance, and stability at elevated temperatures. It is widely used in aerospace applications such as turbine blades, exhaust systems, and engine components, where reliability under extreme heat and stress is critical. Beyond aerospace, Inconel also plays a vital role in energy, chemical processing, and marine engineering industries.

Titanium

Titanium is a lightweight, high-strength metal renowned for its exceptional strength-to-weight ratio, corrosion resistance, and fatigue performance. These properties make it ideal for critical aerospace components such as fasteners, brackets, structural frames, and engine parts, where both strength and weight reduction are essential. Its excellent performance under extreme temperatures and stress ensures long-term reliability in demanding flight environments.

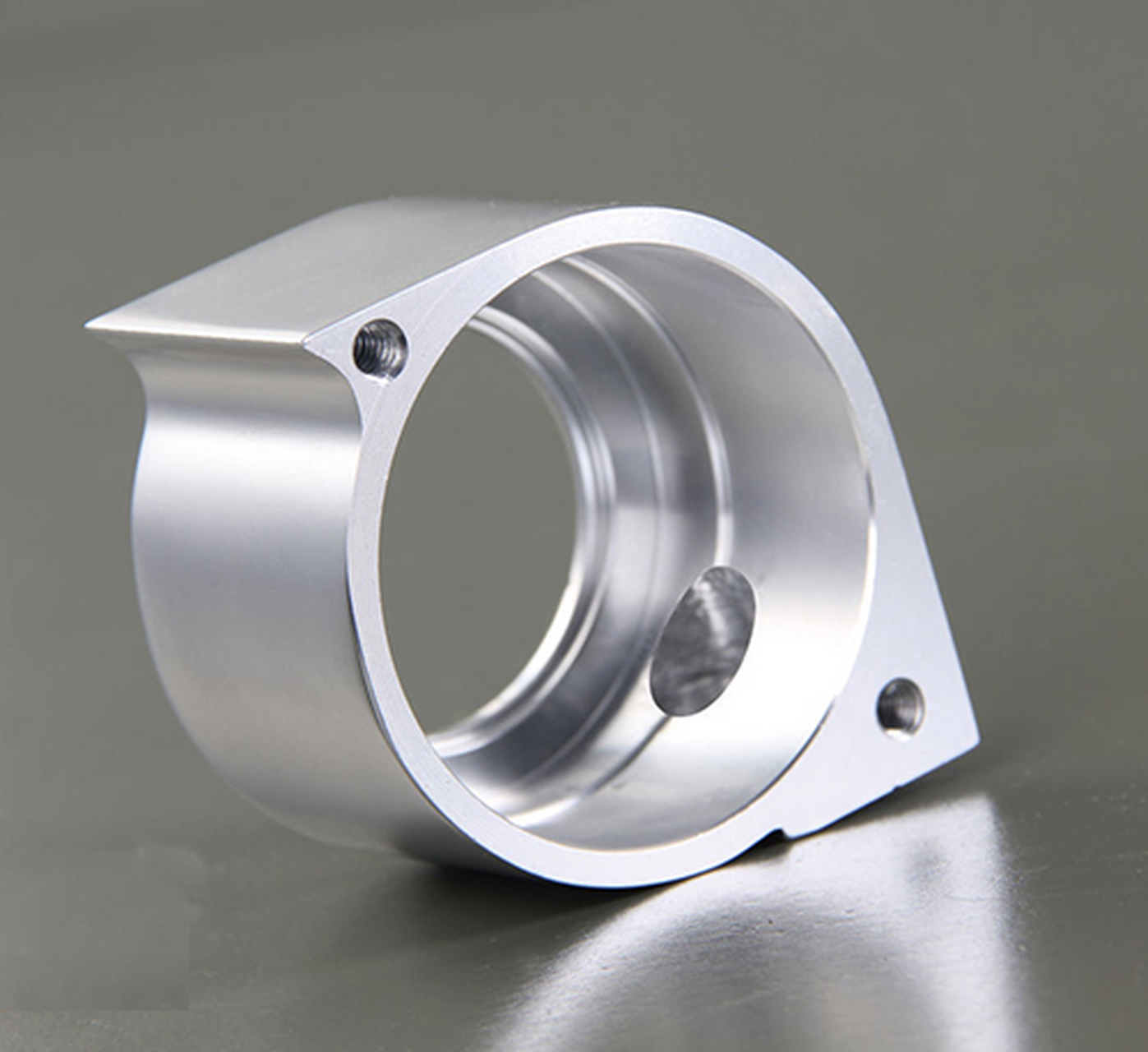

Aluminum

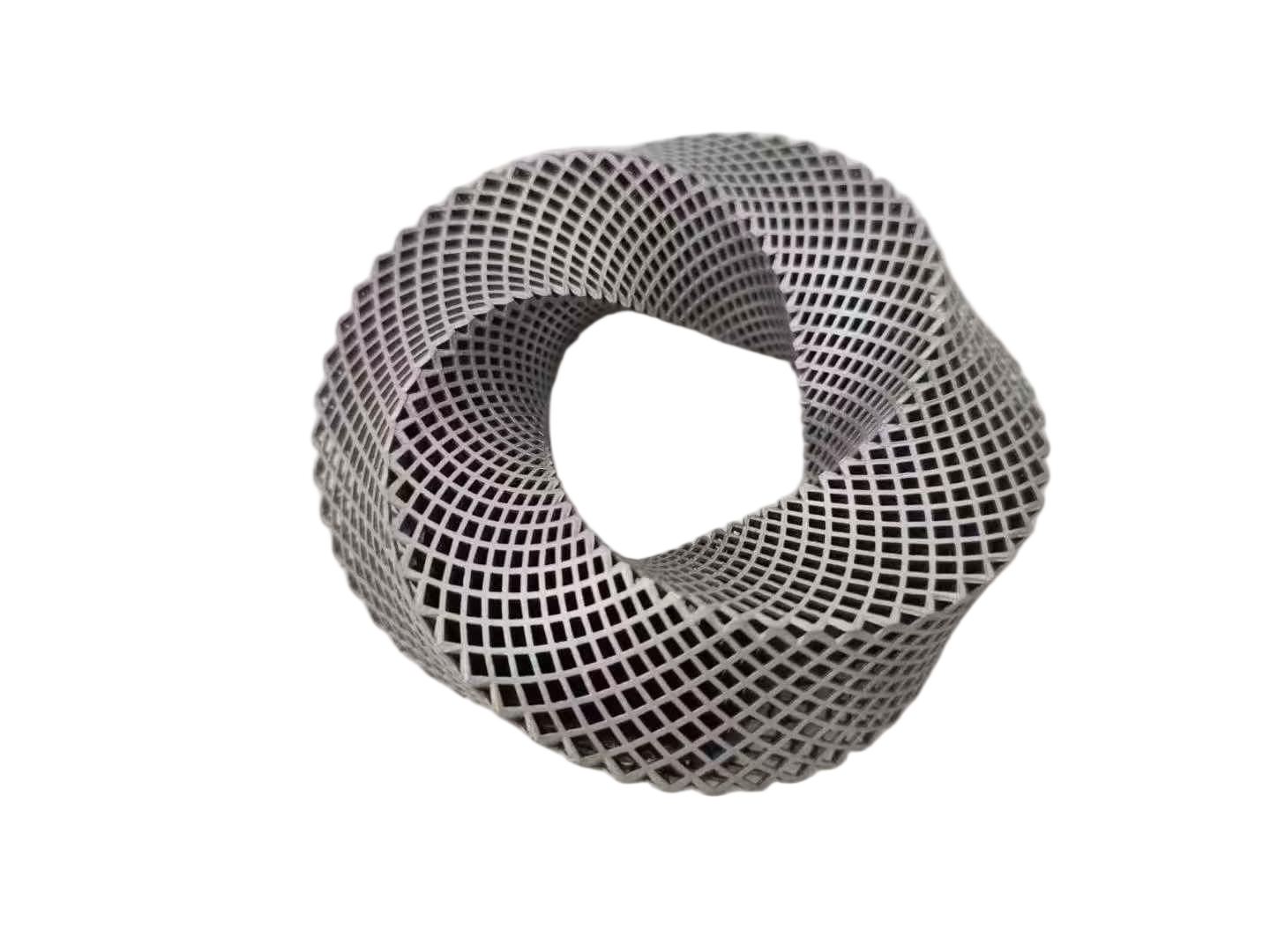

Aluminum is a lightweight yet strong metal prized for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. These properties make it an ideal material for aerospace enclosures, brackets, and structural components that must withstand high loads while minimizing overall weight. Aluminum is also highly versatile — suitable for both precision-machined and 3D-printed parts — making it a key material in modern aerospace manufacturing and prototyping.

Stainless Steel

17-4 PH stainless steel is widely used in the aerospace industry due to its high strength, excellent corrosion resistance, and stable mechanical properties at temperatures up to 600°F (316°C). Its combination of hardness, toughness, and dimensional stability makes it ideal for critical aerospace components such as landing gear parts, fasteners, shafts, and structural fittings. 17-4 PH can be heat-treated to achieve a precise balance of strength and ductility, ensuring reliable performance in demanding flight and high-stress environments.

Liquid Silicone Rubber

Fluorosilicone materials are widely used in aerospace applications due to their outstanding resistance to fuels, oils, and high-temperature aging. Their excellent chemical and thermal stability makes them ideal for critical sealing components in fuel systems, such as O-rings, gaskets, and diaphragms, ensuring reliable performance under extreme operating conditions. With superior elasticity and durability, fluorosilicone seals maintain tight tolerances and long service life even in high-pressure and high-temperature aerospace environments.

Advanced Surface Finishes for the Aerospace Industry

We provide high-performance surface finishing solutions designed to meet the demanding standards of the aerospace industry. Our processes enhance durability, corrosion resistance, and overall performance of critical components, ensuring reliability in extreme environments.

Name

Applicable Materials

Surface Condition

Thickness

Color

As machined

Metals & Plastics

Tool marks visible

——

——

Anodized

Aluminum

Tool marks visible,

Smooth, Matt & Gloss

0.002mm ~ 0.05mm

colors can be

matched as needed

Chromate Conversion Coating

Aluminum

Tool marks visible

Smooth and Matt

0.25 ~ 1 μm

Clear/ slight yellow tint

Sanding & Polishing

Metals

Tool marks visible,

Smooth, Matt & Gloss

0.002mm ~ 0.05mm

colors can be

matched as needed

Nickel Plating

Metals

Gloss

0.002mm ~ 0.05mm

Silver

Chrome Plating

Metals & Plastics

Satin & Gloss

0.001mm ~ 0.3mm

Silver

Powder coat

Metals

Matt, Gloss & Texture

0.05mm ~ 0.15mm

colors can be

matched as needed

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

| 1 | Advanced Inspection Equipment | ||||

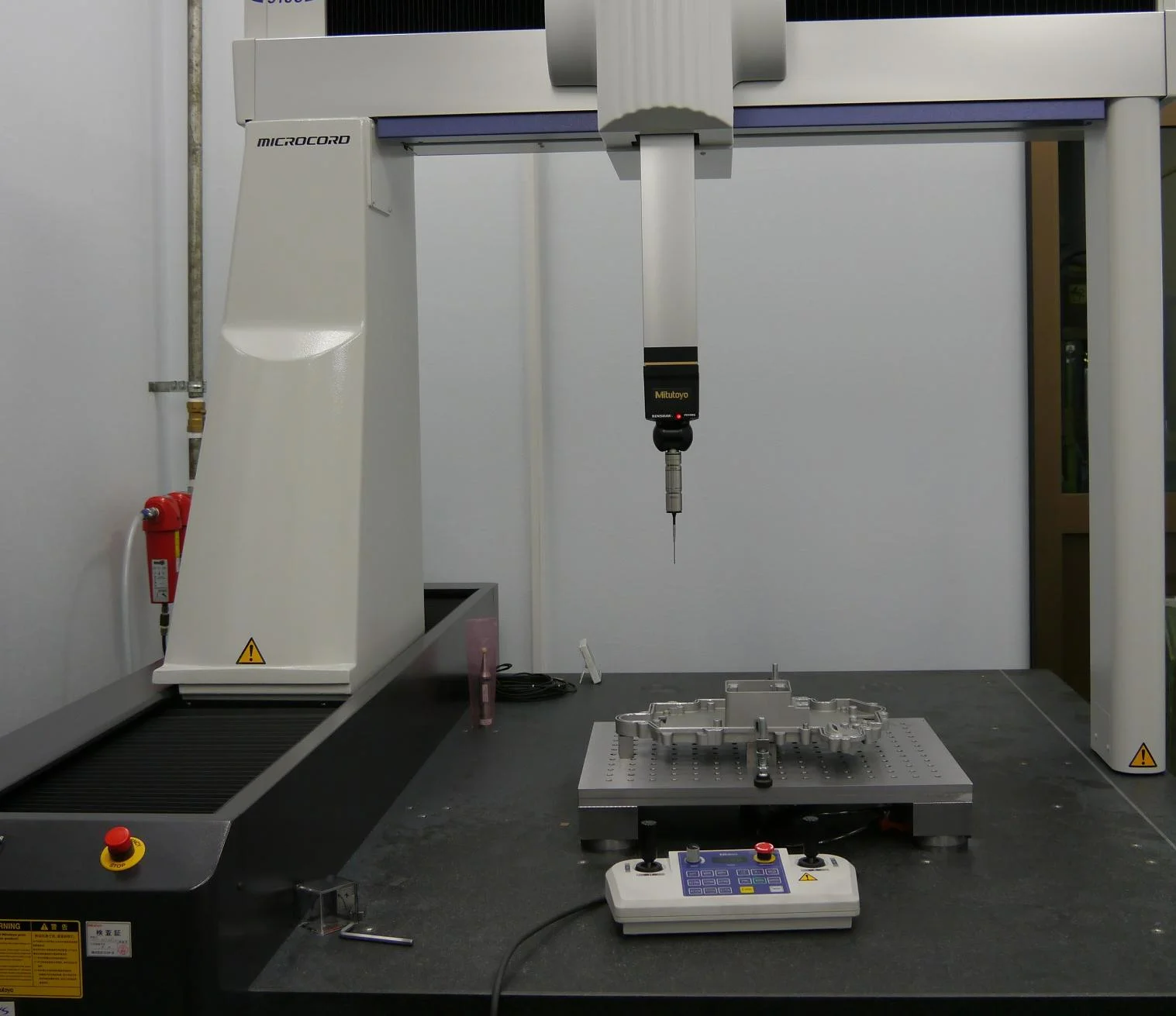

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

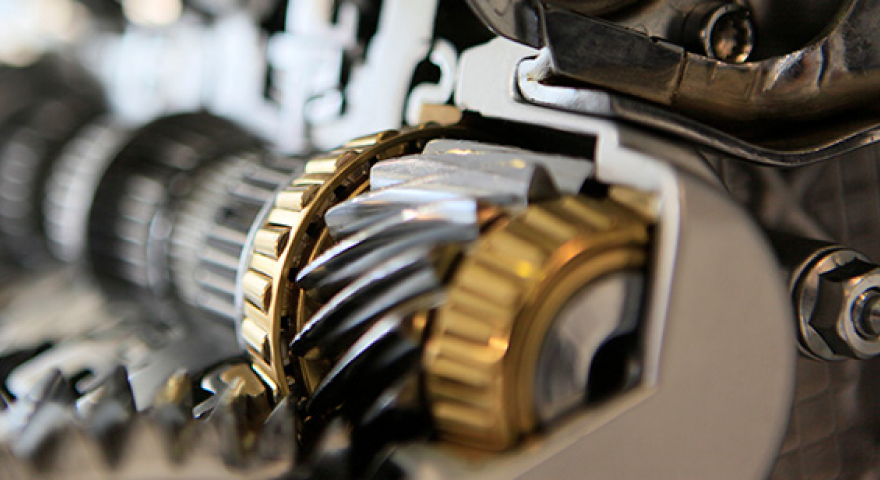

Common Aerospace Applications

Our manufacturing services encompass a range of specialized capabilities tailored to the aerospace industry. Below are some of the most frequently encountered applications we address.