How Horizon Supports Automotive Companies

Rapid Prototyping

Reduce design risk through rapid iteration and precise prototyping with production-grade materials. Achieve faster development without compromising quality, enabling thorough design validation, optimized performance, and a smooth transition from early concept to large-scale manufacturing.

Technology -empowered services

With our rapid prototyping and low- volume production services, you can accelerate the iterative development process. Once development is mature, work with our application engineering team to meet all production needs for your end applications in the automotive

field.

Short lead time

By leveraging our comprehensive equipment, extensive network of partners, and highly skilled engineering team, we are able to rapidly deliver high-quality, high-precision components, ensuring exceptional performance, strict adherence to specifications, and reliable results for every stage of your project.

Automotive Services for Automotive Products

The processing speed, precision, and reliability you are familiar with remain unchanged, and you can also gain stricter tolerances, bulk pricing, and other more advanced processing advantages.

- Machined parts can be delivered as fast as 1 day; with plating or anodizing required, completion can be as fast as 4 days.

- Higher-volume machined parts are more cost-effective.

- Tolerances can be precisely controlled to ±0.001 inch (0.020 mm).

Within a few days, you can acquire injection-molded parts that are both cost-effective and high-quality. Leveraging our free injection molding feasibility consulting service, design and injection molding processes will be significantly expedited, helping you save time and costs.

Within a few days, you can acquire injection-molded parts that are both cost-effective and high-quality. Leveraging our free injection molding feasibility consulting service, design and injection molding processes will be significantly expedited, helping you save time and costs.

- No minimum order quantity restriction, with bulk pricing plans.

- A wide range of materials available.

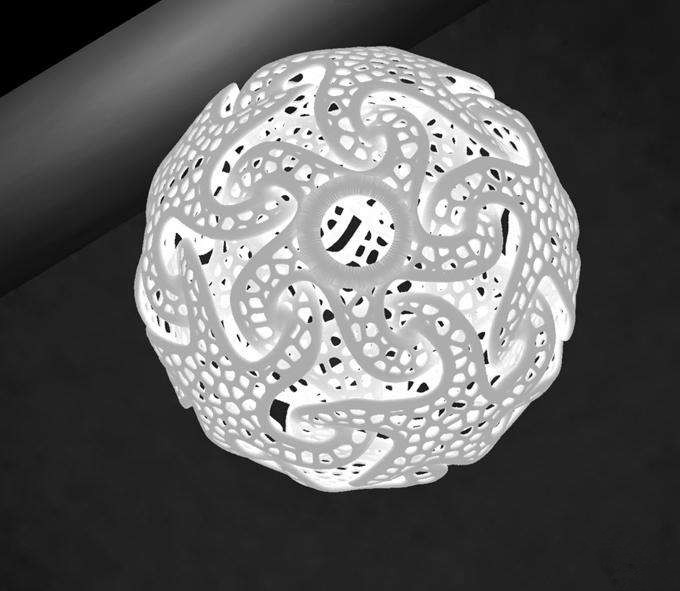

We offer a variety of additive manufacturing technologies to help you achieve cost-effective prototyping, as well as highly precise and repeatable mass production of components.

We offer a variety of additive manufacturing technologies to help you achieve cost-effective prototyping, as well as highly precise and repeatable mass production of components.

- Additive manufacturing technologies encompass processes such as metal 3D printing, stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM), among others.

- We offer a variety of plastic and metal materials, with surface treatment solutions also available as options.

From convenient quoting to rapid production, and to diverse post-processing solutions, high-quality sheet metal parts can be obtained within days.

- 5 types of sheet metal materials are available, including aluminum, stainless steel, steel, brass, and copper.

- Encompassing various surface treatment solutions, from welding and assembly to powder coating and screen printing, among others.

Materials for Automotive Applications

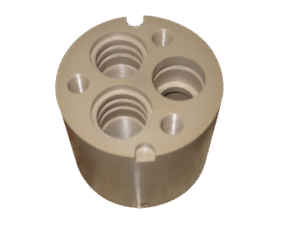

Aluminum

Aluminum, an all-purpose metal prized for its lightweight properties, boasts an excellent strength-to-weight ratio and can be machined or 3D printed.

Thermoplastics

Numerous thermoplastics are available, such as POM (acetal), PEEK (polyetheretherketone), and we also accept customer-supplied materials.

Nylon

We utilize SLS and MJF technologies to rapidly manufacture functional nylon prototypes. A variety of standard nylon materials are available, and when prototypes require superior mechanical properties, we also offer glass-filled nylon options to significantly enhance stiffness, strength, and thermal stability

Liquid Silicone Rubber

Silicone rubber materials such as oil-resistant fluorosilicone can be used for manufacturing gaskets and seals, along with high-performance perfluoroelastomer (FFKM). Additionally, we offer transparent silicone rubber suitable for food and medical applications.

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

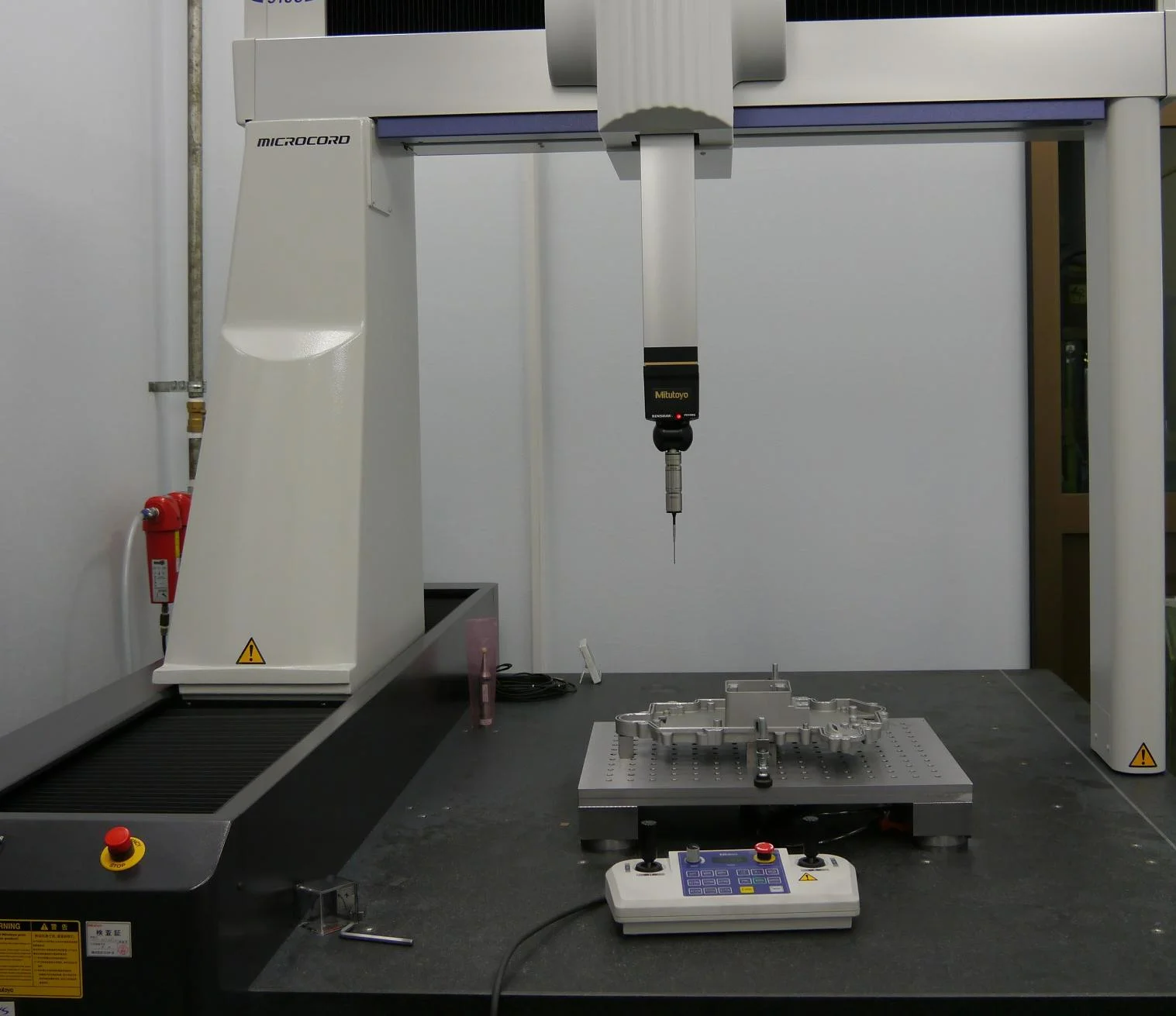

| 1 | Advanced Inspection Equipment | ||||

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

Common Automotive Applications

We have several capabilities within our manufacturing services catered to the automotive industry. Here are a few applications we frequently see.