Industrial Machinery

Prototyping & Manufacturing

Access premium manufacturing solutions tailored for your custom industrial machinery prototypes and end-use production parts. Accelerate time-to-market, mitigate risks, and optimize production workflows—backed by flexible on-demand manufacturing capabilities at highly competitive pricing.

How Horizon Supports Industrial Equipment Companies?

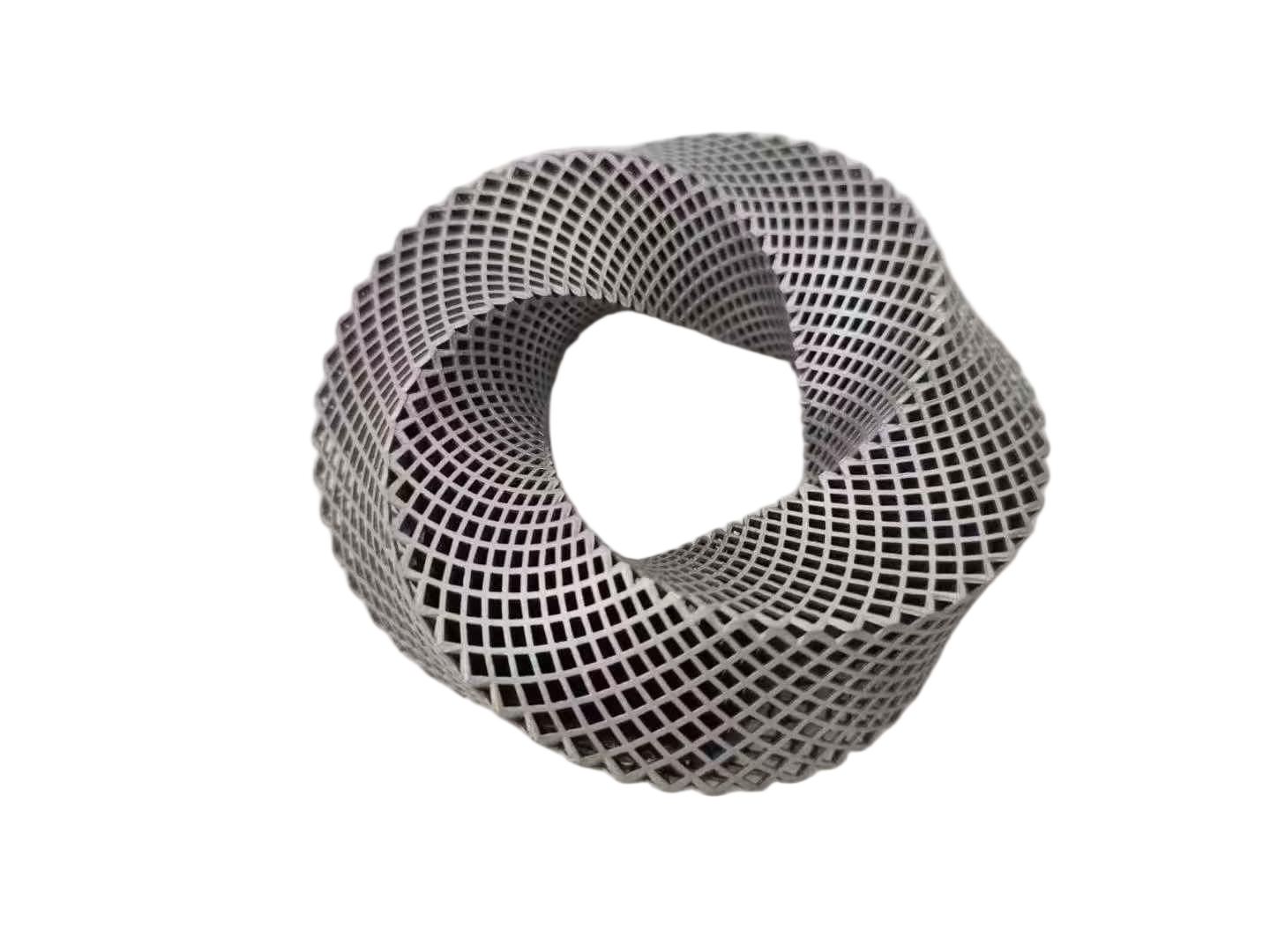

Rapid Prototyping

Reduce design risk through rapid iteration and prototyping with production-grade materials, without compromising development speed.

Technology-empowered services

With our rapid prototyping and low-volume production services, you can accelerate the iterative development process. Once development is mature, work with our application engineering team to meet all production needs for your end applications in industrial machinery.

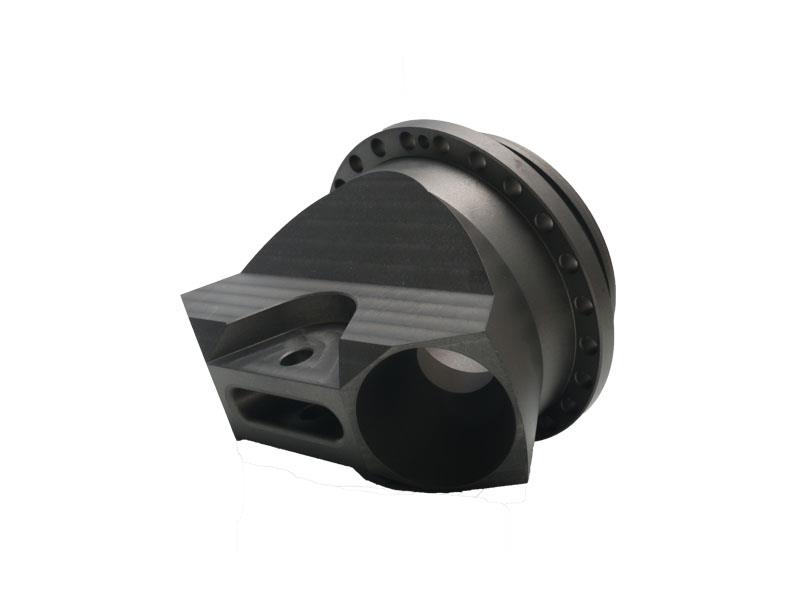

Short lead time

Leveraging comprehensive equipment, extensive partners, and a professional engineering team, we are able to swiftly deliver high-quality, high-precision components.

Our Manufacturing Services

Materials for Industrial Applications

Aluminum

Aluminum, an all-purpose metal prized for its lightweight properties, boasts an excellent strength-to-weight ratio and can be machined or 3D printed.

Thermoplastics

Numerous thermoplastics are available, such as POM (acetal), PEEK (polyetheretherketone), and we also accept customer-supplied materials.

Steel and Stainless Steel

It offers high strength, easy machinability, and low cost—key traits making it widely chosen. For example, oil and gas fields favor stainless steel for its corrosion resistance. For extreme needs, superalloys like 3D-printed Inconel are a top alternative, built for tough conditions.

Commodity Plastics

As companies modernize existing equipment with digital electronics to meet connectivity demands, a broad range of versatile, cost-effective thermoplastics are being leveraged.

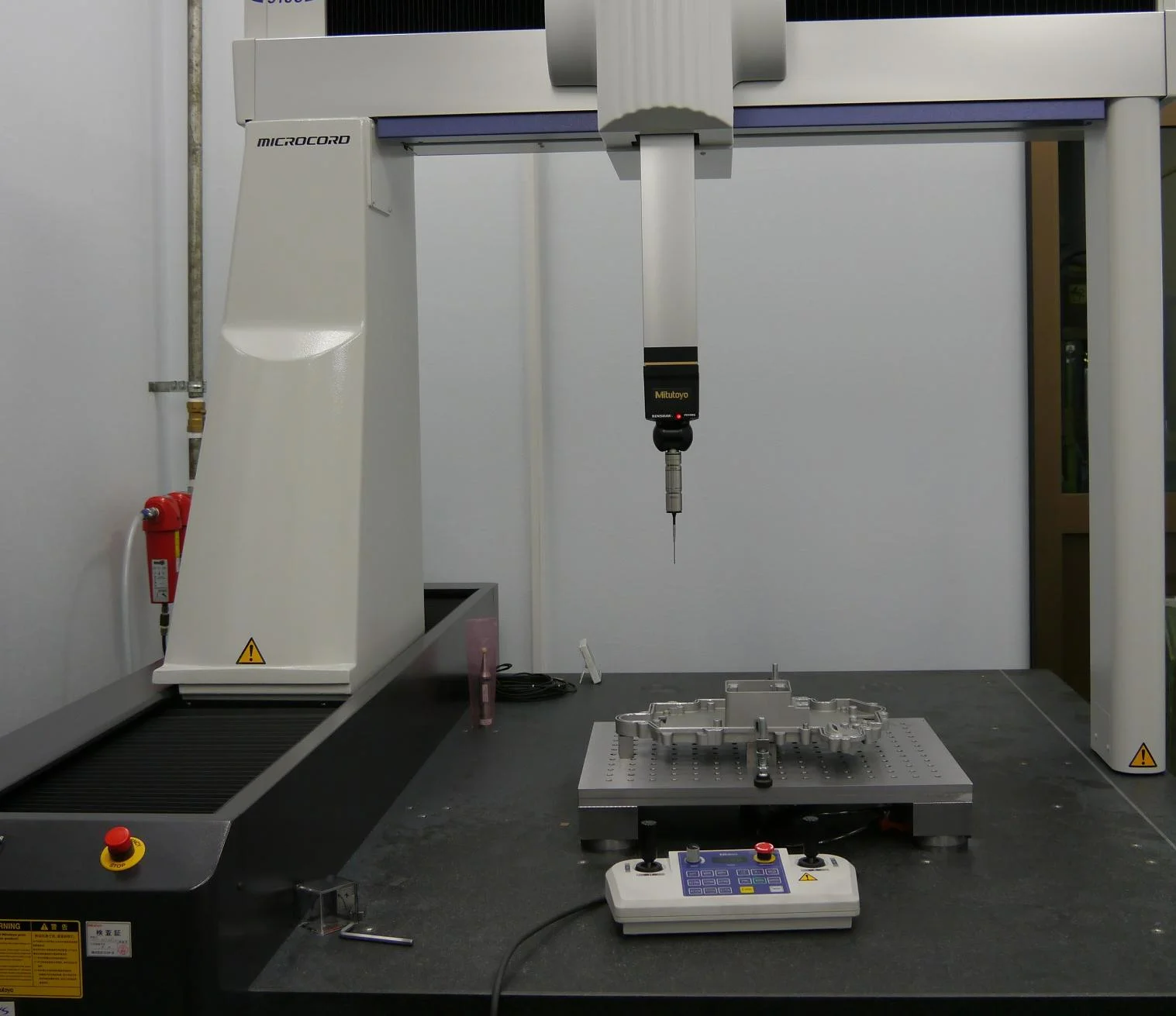

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

| 1 | Advanced Inspection Equipment | ||||

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||