Robotics & Automation Manufacturing Solutions

At the forefront of technological advancement, robotics and automation systems demand custom, high-precision components that can endure mechanical stress, tight tolerances, and complex geometries. HorizonRP specializes in manufacturing solutions tailored for robotics — from early prototyping to low-volume production.

How HorizonRP Serves the Robotics Industry

Rapid Prototyping

Reduce design risk through rapid iteration and prototyping with production-grade materials, without compromising development speed.

Technology-empowered services

With our rapid prototyping and low-volume production services, you can accelerate the iterative development process. Once development is mature, work with our application engineering team to meet all production needs for your end applications in Robotics & Automation.

Short lead time

Leveraging comprehensive equipment, extensive partners, and a professional engineering team, we are able to swiftly deliver high-quality, high-precision components.

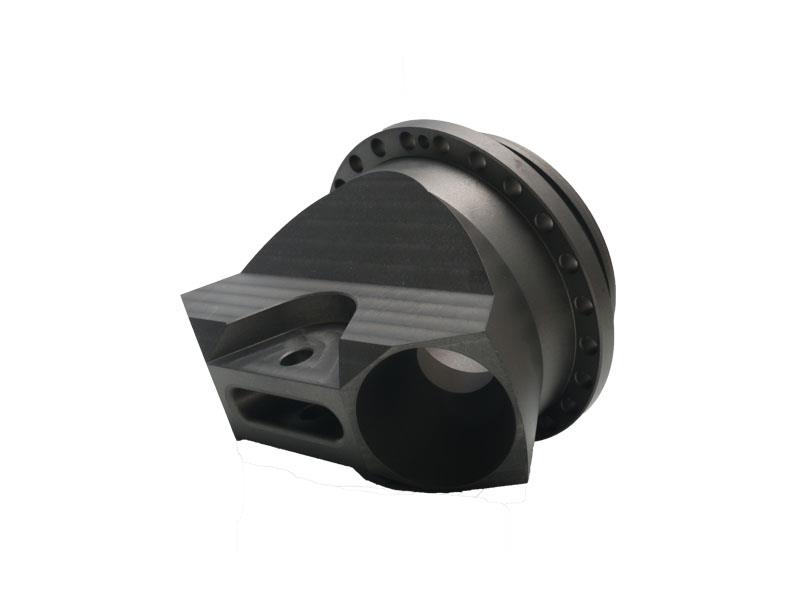

Manufacturing Services for Robotics Products

Materials for Robotics Applications

Aluminum

Aluminum—lightweight yet stiff, ideal for structural frames,an all-purpose metal prized for its lightweight properties, boasts an excellent strength-to-weight ratio and can be machined or 3D printed.

Steel and Stainless Steel

Steel & Stainless Steel — for load-bearing or wear-critical parts,It offers high strength, easy machinability, and low cost—key traits making it widely chosen. For example, oil and gas fields favor stainless steel for its corrosion resistance. For extreme needs, superalloys like 3D-printed Inconel are a top alternative, built for tough conditions.

Copper & POM

Copper& POM — for conductors, bearings, seals, flexible components,Acetal delivers exceptional dimensional stability and low friction—both mission-critical properties for robot components subject to sliding motion or repetitive operations. It also maintains a cost-effective profile compared to other standard industrial materials.

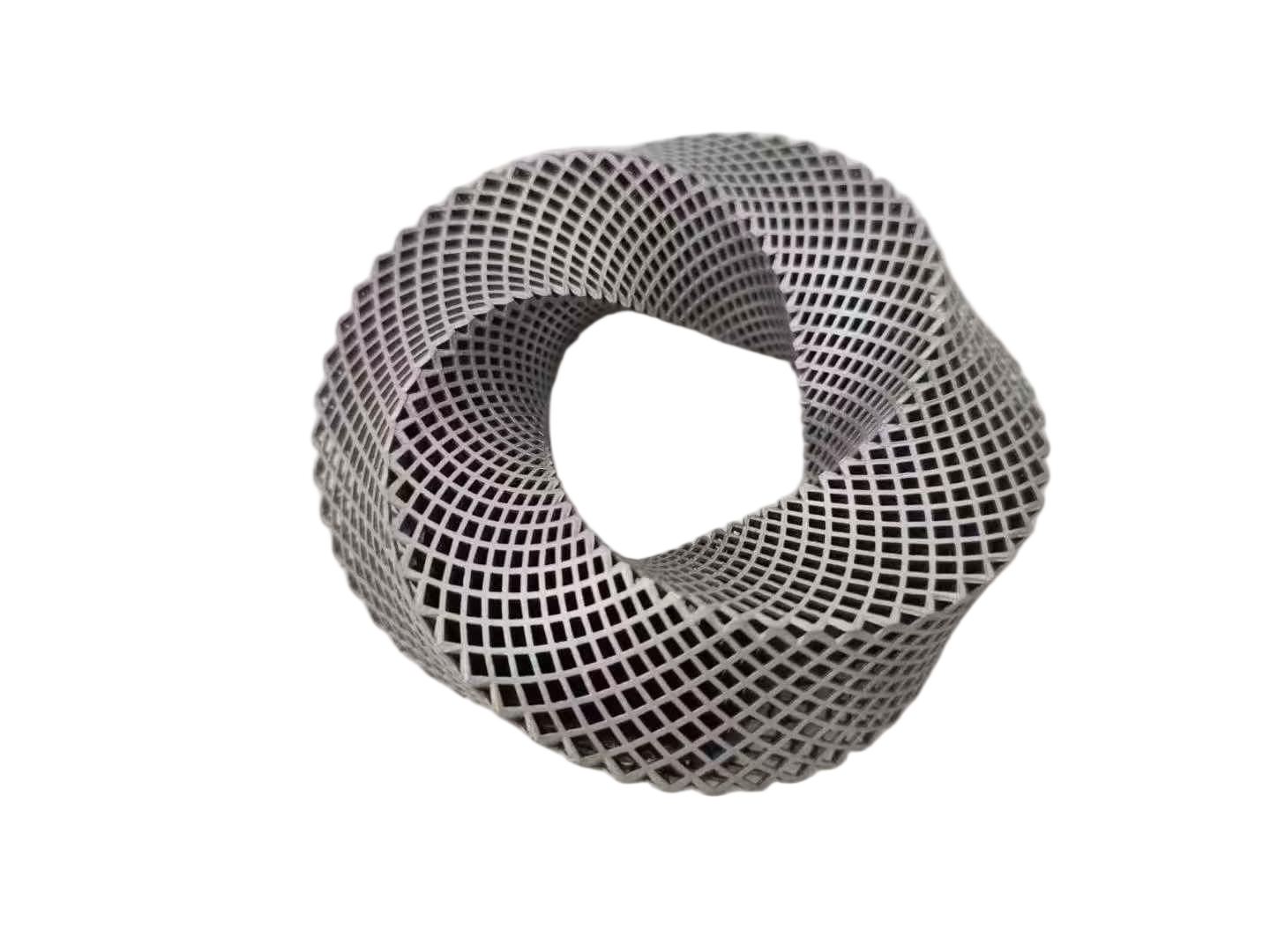

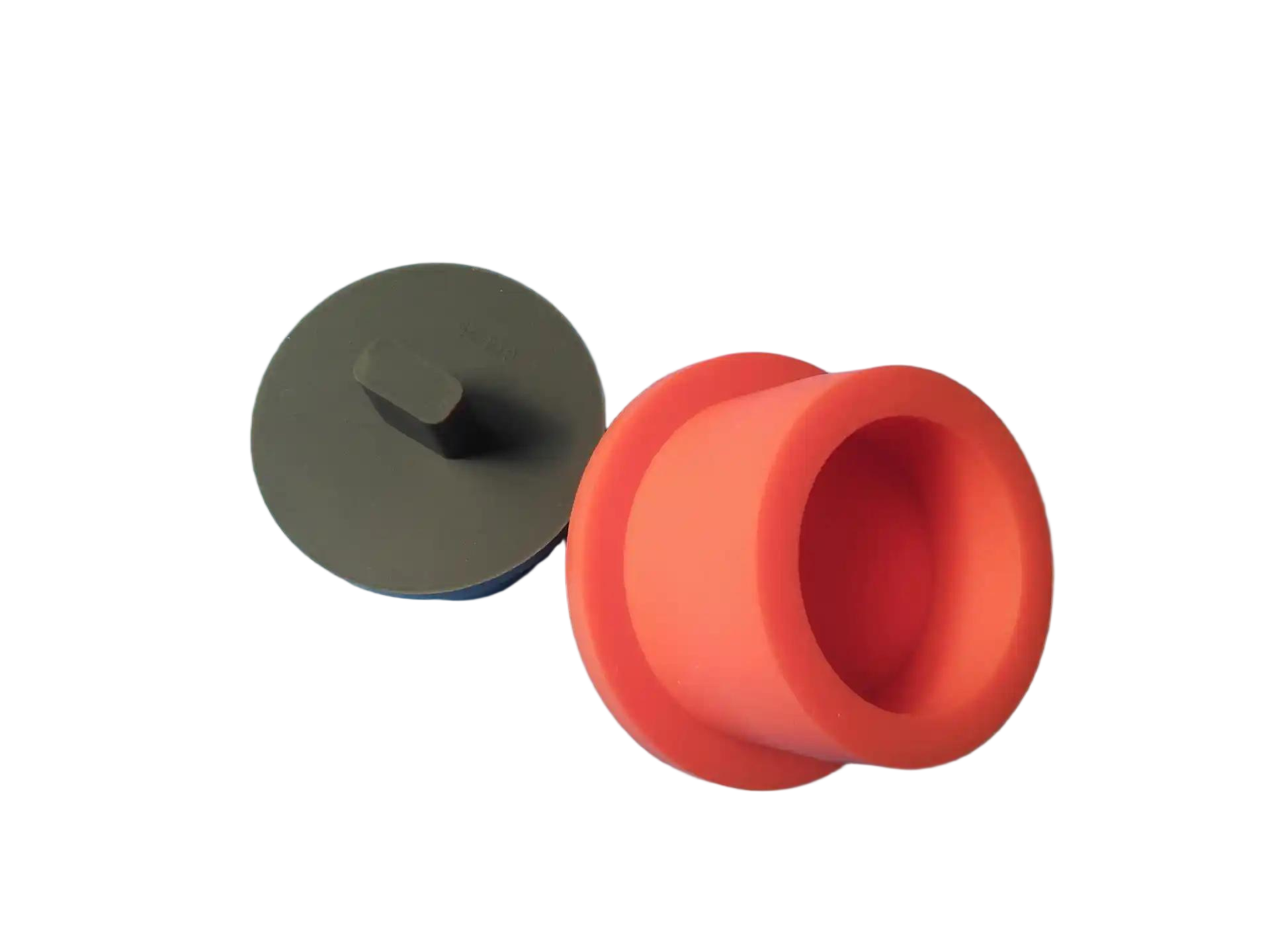

Elastomeric silicone rubber

With the rise of soft robotics, elastomers are increasingly used in robots. They enable delicate tasks that require flexibility and gentle handling. In conventional robots, elastomers are also applied in components like semiconductors and casings where flexibility or cushioning is needed.

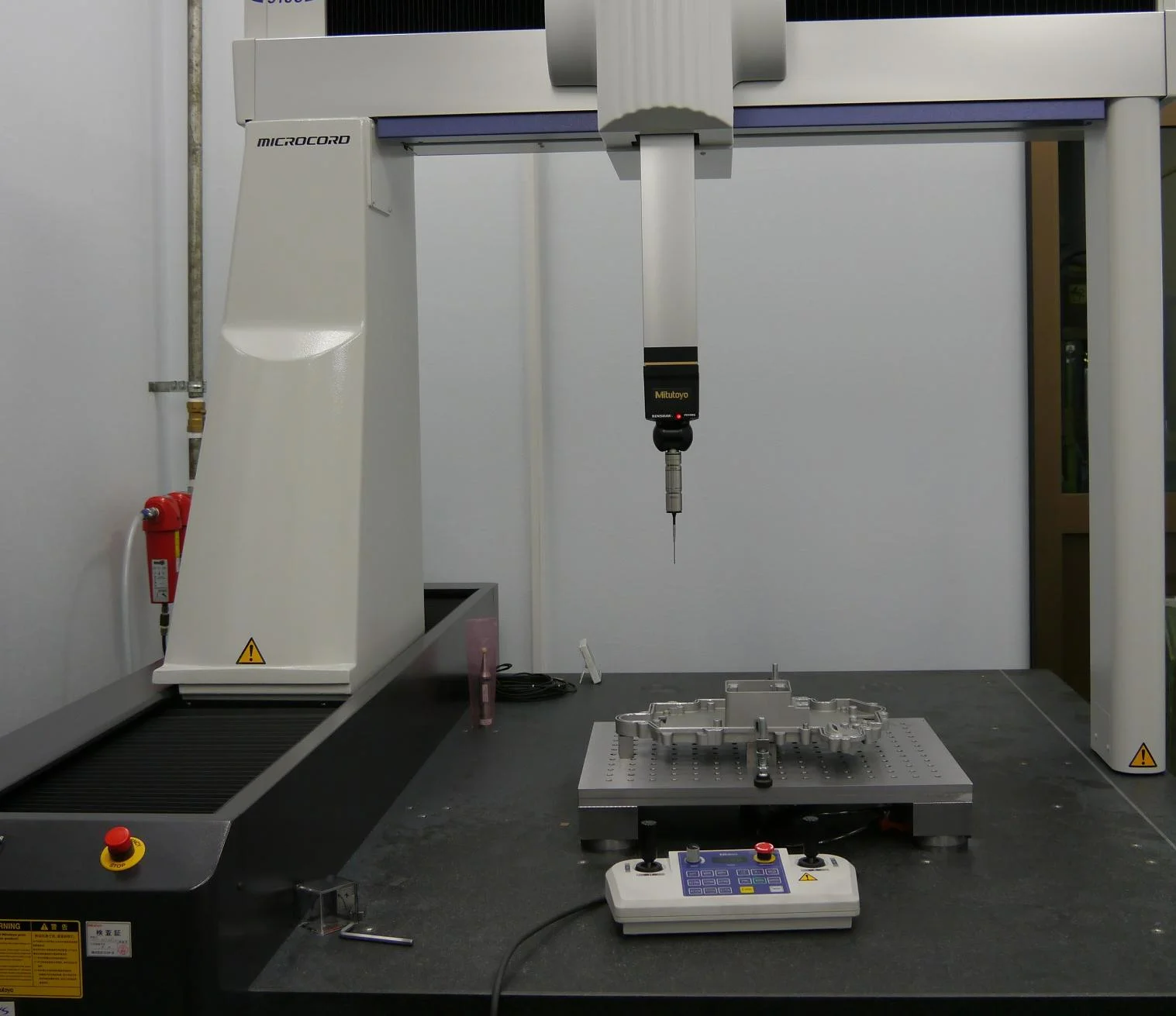

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

| 1 | Advanced Inspection Equipment | ||||

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

Common Robotics Applications

Our robotics manufacturing services include CNC machining, injection molding, additive manufacturing, and sheet metal fabrication — all optimized for robotics designs’ complexity and performance demands. Below are some of the most common applications we regularly support.