Flexible Custom CNC Milling Services

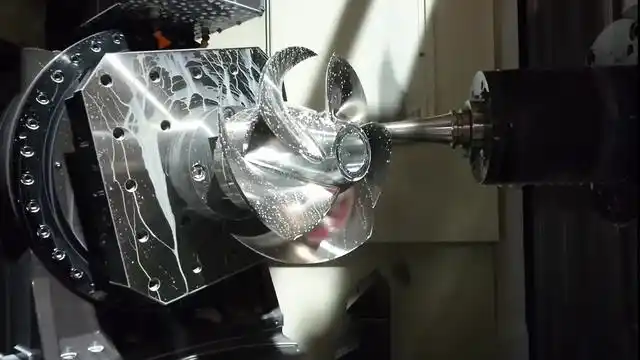

Equipped with advanced 3-axis and 5-axis CNC milling machines, we rapidly produce metal and plastic prototypes and parts. No matter the project size, we ensure consistent quality, tight tolerances, and fast turnaround time.

Get a quote instantly and order your custom CNC machined parts at the most competitive prices.

Innovative Companies We Support

CNC Milling for Every Stage

3-Axis CNC Milling

With 3-axis CNC milling, precision meets affordability. It’s your go-to for simple parts that still demand accuracy.

4-Axis CNC Milling

Compared to three-axis milling, four-axis milling not only significantly reduces the number of setups and fixtures but also the ideal solution for machining long parts with side-wall features.

Flexible CNC Milling Solutions

Our advanced online CNC machining services adapt seamlessly to your design requirements and development timelines. With fast quoting and remote ordering, you can easily kick-start projects from anywhere. We produce prototypes, test parts, and low-volume production efficiently, supporting a wide range of materials with up to ±0.01mm precision——meeting the hight-speed and accuracy demands of modern product development.

Rapid Prototyping CNC Milling

With our custom milling services, Horizon delivers high-precision CNC prototypes, functional parts, and intricate machined components quickly—supporting a wide range of applications and providing a reliable foundation for full-scale production.

Low Volume CNC Milling

Our low-volume milling services provide fast, cost-effective delivery of precision parts. With flexible production, rapid turnaround, and no tooling costs, we help you validate designs, transition smoothly to full-scale production, or fulfill small-batch orders with consistent, high-quality results.

Why Choose Horizon?

With a network of over 50 trusted partners, we can seamlessly support everything from rapid prototyping and small-batch trials to full-scale mass production.

I

Fast Delivery

Whether it’s prototypes or large-scale orders, we deliver quickly without compromising quality keeping your projects on schedule.

II

Advanced Equipment

With state-of-the-art 5-axis CNC machines and strict inspection systems, we guarantee precision in every part.

III

A Team That Understands You

We don’t just machine parts-we help optimize your design, saving you time and cost while improving performance.

IV

Trusted By Many Industries

From aerospace to medical, automotive to electronics, clients across industries rely on us for long-term partnerships.

We offer comprehensive custom machining services, ranging from prototypes delivered in as fast as one day to high-volume production of complex parts, all executed efficiently. With our strong machining capabilities and extensive manufacturing network, we can accommodate larger sizes, higher complexity, and stricter tolerances, providing reliable solutions for our clients.

How to Work With Us

How to Work With Us

Our ordering process

3-axis machining Vs 5-axis Machining-Which Suits Your Project?

Choosing the right machining method is not only the key to achieving efficient and precise production, but also a way to reduce costs. Both 3-axis and 5-axis machining have their own advantages, capable of handling everything from complex curved surfaces to rotationally symmetric parts. Understanding their characteristics will help you make the best choice for each project.

Feature

3-Axis Machining

5-Axis Machining

Movement

3-axis machining is a precise and versatile method for producing flat surfaces, slots, holes, and simple 3D parts. It offers high accuracy, repeatability, and efficiency, making it ideal for small-batch or straightforward part production. Advanced tooling ensures excellent surface finish and dimensional precision.

Simultaneous, or continuous, 5-axis machining allows all five axes to move at the same time, enabling the machine to adjust its position continuously without stopping. This approach can significantly increase machining speed and efficiency, as there are no interruptions between cutting passes, while also improving surface finish on complex parts.

Complexity

Suitable for flat surfaces, slots, and simple 3D parts; simple in structure.

Surface Quality

Provides smoother surfaces withfewer tool marks, though the surfacequality on complex curves is stillinferior to 5-axis machining.

When machining complex surfaces or intricate structures, it achieves smoother finishes with fewer tool marks.

Efficiency

High production efficiency, but complex parts require multiple setups.

Faster production with fewer setups.

Best For

Flat surfaces, slots, and simple 3D parts.

Components with complex structures and high precision requirements.

Cost & Investment

Both part and equipment costs are lower than those of 5-axis machining.

Higher machine and programming costs.

Our CNC milling capabilities

Maximum Part Size

Minimum Part Size

General Tolerances

Lead Time

3-Axis

1000 x 500 x 500 mm

5 x 5 x 5 mm

±0.1 mm

Simple products can be completed in as little as 1 day.

4-Axis

1000 x 500 x 500 mm

5 x 5 x 5 mm

±0.1 mm

Most projects take 5 days from material procurement to production completion.

5-Axis

2500*1600*500

5 x 5 x 5 mm

±0.05 mm

Most projects take 5 days from material procurement to completion of production.

Tolerances without individual tolerance indications according to ISO 2768-1:1989. Values in millimeters.

| Basic size range | f (fine) | m (medium) | c (coarse) | v (very coarse) |

|---|---|---|---|---|

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | — |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over 2000 up to 4000 | – | ±2.0 | ±4.0 | ±8.0 |

Tolerances for CNC

Horizon applies the ISO 2768-m (medium) standard for machined plastics and the ISO 2768-f (fine) standard for machined metals. Under normal circumstances, CNC machining tolerances can be controlled within the range of ±0.125 mm (±0.005″) to ±0.05 mm (±0.002″). For tighter tolerances, please provide fully detailed 2D drawings. Our engineering team will confirm the critical dimensional requirements with you and strive to achieve the highest precision possible. If 2D drawings are not available, we will apply the ISO 2768-m (medium) standard for machined parts.

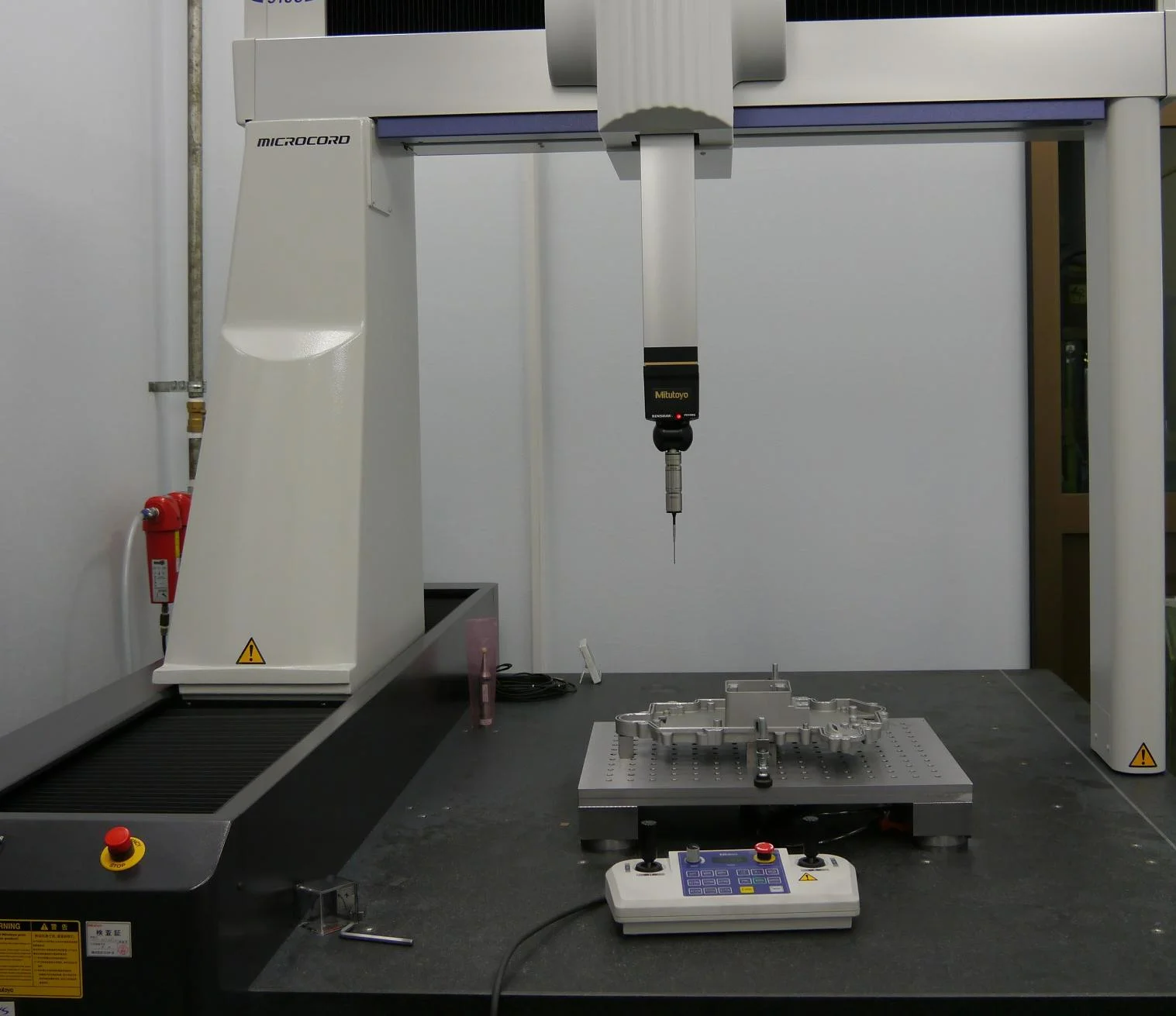

Assurance Qualité

| Portés par l'excellence, nous intégrons la qualité dans chaque détail — des outils avancés aux normes rigoureuses. Nous garantissons une qualité constante et exceptionnelle. | |||||

|---|---|---|---|---|---|

| 1 | Équipements d'Inspection Avancés | ||||

| Nous utilisons des équipements d'inspection professionnels pour des mesures et validations précises. Un spectromètre analyse la composition des métaux, un instrument de mesure 2,5D vérifie les caractéristiques détaillées, une machine de mesure par coordonnées (MMC) contrôle les structures tridimensionnelles complexes, et des comparateurs de hauteur assurent la précision des dimensions fondamentales. | |||||

| 2 | Système de Gestion de la Qualité Strict | ||||

| De l'inspection du premier article aux contrôles en cours de production et aux tests finaux avant expédition, chaque étape est régie par un système de gestion rigoureux pour garantir une qualité constante. | |||||

| IQC (Contrôle Qualité Entrant) | FAI (Inspection du Premier Article) | ||||

| IPQC (Contrôle Qualité en Cours de Production) | Rapport d'Inspection CMM | ||||

| FQC (Contrôle Qualité Final) | RID (Rapport d'Inspection Dimensionnelle) | ||||

| OQC (Contrôle Qualité Sortant) | RAC (Rapport d'Action Corrective et Préventive) | ||||

| Certificats de Matériaux | ISO 9001 | ||||

CNC Milling Materials

We offer a wide range of CNC machining materials, including metal alloys, plastics, and composites. All materials are carefully selected for high strength, excellent durability, and cost efficiency. Our engineering team provides professional DFM (Design for Manufacturability) guidance to help optimize your plastic and metal part designs for efficient production. Contact us or upload your CAD file to explore material options, receive instant quotes, and access customized manufacturing solutions.

Metal

Bronze

Matériau en Bronze et Alliage Cuivre-Étain

Magnésium

Matériaux En Magnésium Et Alliages De Magnésium

Titane

Titane

Acier Doux

Acier Faible Teneur En Carbone (Acier Doux)

Acier Inoxydable

Matériau et alliages en acier inoxydable

Cuivre

Matériaux En Cuivre Et Alliages De Cuivre

Laiton

Matériau en Laiton & Alliages de Laiton

Aluminium

Aluminum Material & Aluminum Alloys

Plastics

PVC

Matériau Plastique PVC (Polychlorure de Vinyle)

Le polychlorure de vinyle (PVC) est un polymère thermoplastique largement utilisé, caractérisé par d’excellentes propriétés mécaniques, une résistance exceptionnelle à la corrosion et de superbes performances d’isolation électrique. Grâce à l’ajout de divers additifs, il peut être adapté pour répondre à des besoins spécifiques. En raison de sa combinaison unique de propriétés, le PVC trouve de larges applications dans des domaines tels que la construction, l’industrie, l’emballage et le secteur de la santé.

PMMA (Acrylic)

Matériau d’Ingénierie en PMMA (Acrylique)

L’acrylique (également connu sous le nom de polyméthacrylate de méthyle, PMMA) se distingue non seulement par ses excellentes performances optiques, mais aussi par sa remarquable résistance aux UV. Avec une transmission lumineuse pouvant atteindre 92 %—comparable à celle du verre—il est devenu un matériau prisé pour des applications variées, allant des enseignes au néon dans les centres commerciaux et des panneaux de vitrines de musées aux lentilles optiques de précision et aux couvercles de projecteurs de scène.

PEEK

Matériau d’Ingénierie en PEEK (Polyétheréthercétone)

Le PEEK (polyétheréthercétone) est un thermoplastique haut de gamme, largement reconnu pour son exceptionnelle stabilité thermique, sa grande résistance mécanique, sa résistance chimique, sa stabilité dimensionnelle ainsi que, dans de nombreux cas, sa biocompatibilité et ses propriétés d’isolation électrique. Il est utilisé dans des environnements extrêmes tels que l’aérospatiale, les implants médicaux, l’électronique et l’industrie des semi-conducteurs.

Nylon

Matériau d’Ingénierie en Nylon (Polyamide)

Le nylon (polyamide) est un thermoplastique technique polyvalent, reconnu pour sa haute résistance mécanique, son excellente résistance à l’usure, sa bonne stabilité chimique et sa robustesse. Il est largement utilisé dans de nombreux secteurs pour la fabrication d’engrenages, de roulements, de bagues, de composants automobiles, de pièces industrielles et bien d’autres applications.

Sa facilité d’usinage, associée à sa résistance chimique, le rend également adapté aux applications dans les industries automobile, aérospatiale et médicale. Grâce à sa combinaison remarquable de propriétés, le nylon s’impose comme un matériau polyvalent et fiable pour une large gamme d’applications d’usinage CNC.

POM

Matériau d’Ingénierie en POM (Polyoxyméthylène / Acétal)

Le POM (polyoxyméthylène), également connu sous le nom d’acétal, est un thermoplastique technique haute performance apprécié pour sa rigidité, sa faible friction, son excellente résistance à l’usure et sa bonne stabilité dimensionnelle. Il est souvent utilisé dans des pièces mécaniques de précision nécessitant des performances durables et peu d’entretien.

ABS

ABS (Acrylonitrile Butadiène Styrène) Matériau

L’ABS (Acrylonitrile Butadiène Styrène) est un thermoplastique technique largement utilisé, connu pour son excellent équilibre entre résistance, robustesse et facilité de mise en forme. Combinant la rigidité de l’acrylonitrile et du styrène avec la résistance aux chocs du butadiène, l’ABS est couramment employé dans les produits grand public, les boîtiers, les capots et divers composants structurels.

CNC milling supports a wide range of additional metals, plastics, and composites. Visit our materials page for a full list.

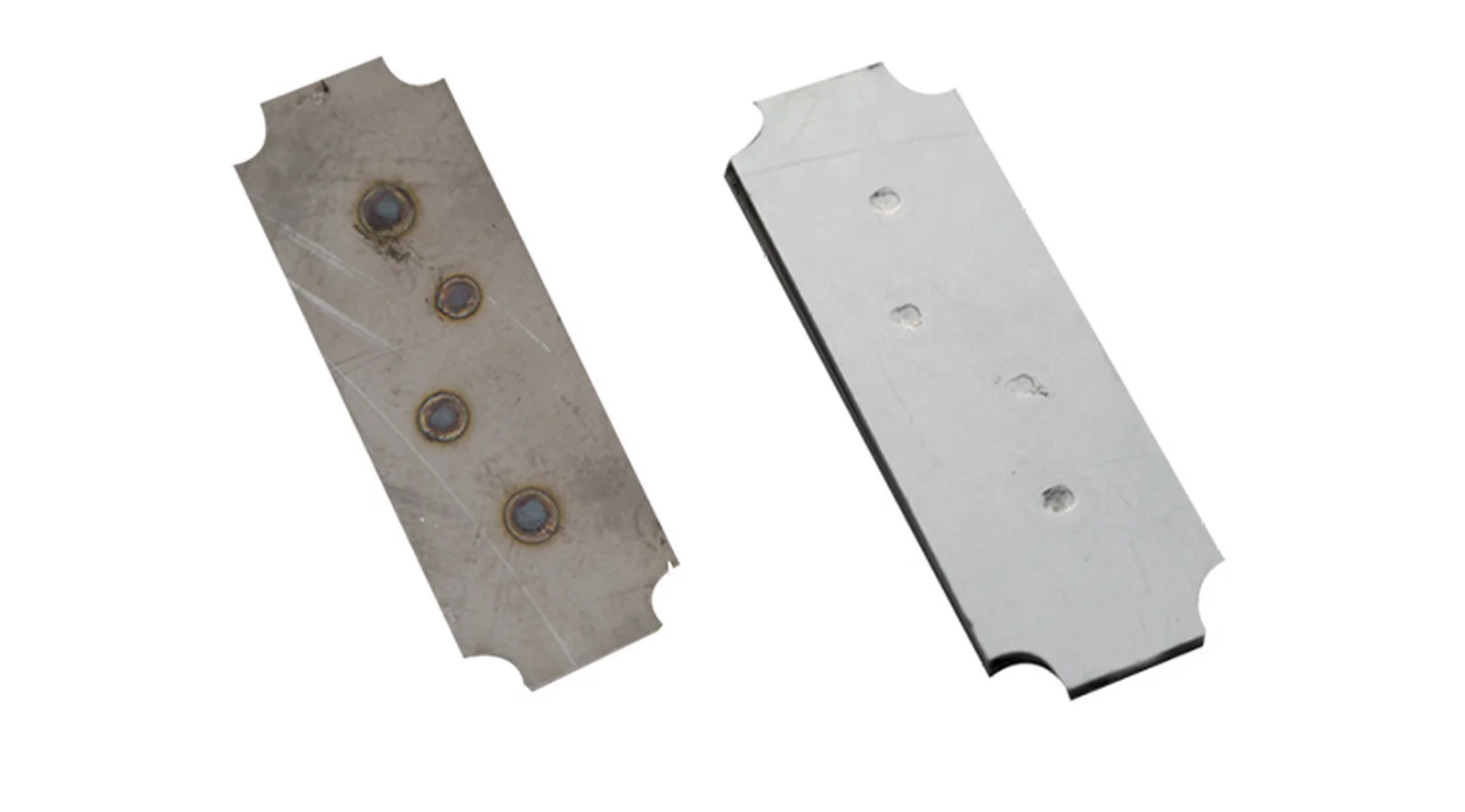

Surface Finish and Post-Processing Options

As machined

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

What is CNC Milling and How Does it Work?

CNC milling is a subtractive manufacturing process. It starts by fixturing a block of metal or plastic material inside the CNC mill. Using G-code, the CNC machine is programmed to rapidly mill out parts from the block of raw material. Our 3- and 5-axis CNC machines are equipped with various toolsets to maximize efficiency and production speed. Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices like anodizing and chromate plating. When the run is complete and your required surface finish is applied, parts are boxed and shipped shortly thereafter.