Compare 3D Printing Materials

Explore and compare 3D printing materials to find the best fit for your project. From durable plastics to flexible resins, our guide highlights key properties like strength, flexibility, and surface finish, helping you choose the right material for prototyping, production, or custom parts.

PLA

Process: FDM

Durability, Biodegradable, RichColors, Economical

PLA is a high-quality, high-performance, and cost-effective 3D printing material, offering excellent layer adhesion and impact resistance, resulting in durable and long-lasting prints. The base series comes in up to 30 colors, ensuring uniform color consistency and stable printing quality. PLA is made from renewable plant-based resources, eco-friendly, non-toxic, and biodegradable. It is reliable, easy to use, and provides high cost-performance with a wide range of colors, making it an ideal choice for home, education, and industrial printing.

PA+GF

Process: SLS or MJF

Temperature Resistance, Durability, Dimensional Stability

PA+GF is a polyamide powder material reinforced with glass beads, which significantly improves stiffness and dimensional stability. Compared with unfilled polyamide, this material offers higher heat resistance and demonstrates excellent long-term wear performance. However, due to the addition of glass, its impact strength and tensile strength are relatively lower than those of other nylons.

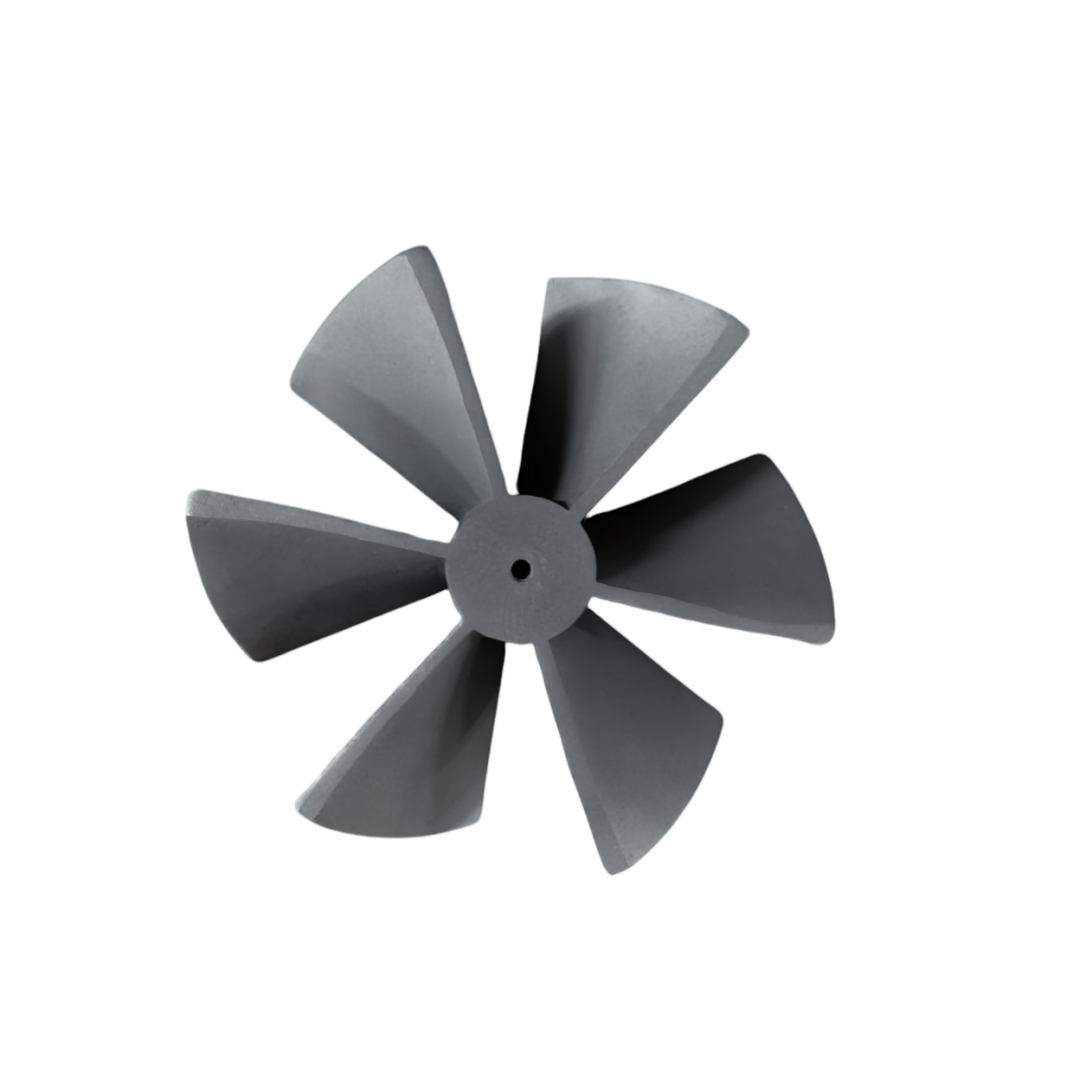

Inconel 718

Process: SLM

Fatigue Resistant, Temperature Resistance, Corrosion Resistance, Strength

Inconel 718 is known for its outstanding high-temperature strength, creep resistance, and corrosion resistance. The material can withstand operating temperatures above 700°C while maintaining excellent fatigue and fracture resistance. Through additive manufacturing, GH4169 can produce parts with complex geometries and is widely used in aerospace engines, gas turbines, high-temperature molds, and high-performance industrial components.

Disadvantages: High cost; complex heat treatment process; thin-walled structures require careful design; default surface roughness Ra10–12.Stainless Steel 17-4PH

Process: SLM

Corrosion Resistance, HighStrength, Wear Resistant

17-4 PH stainless steel is a precipitation-hardening stainless steel known for its excellent hardness and corrosion resistance. Through vacuum solution heat treatment and H900 aging treatment, printed parts can achieve high strength, high hardness, and good wear resistance. 17-4 PH stainless steel is suitable for manufacturing industrial components that require high strength, corrosion resistance, and complex structures, such as aerospace parts, molds, and high-load machinery.

Disadvantages: Low elongation (≤16% after heat treatment); weak magnetism after heat treatment.