Compare 3D Printing Materials

Explore and compare 3D printing materials to find the best fit for your project. From durable plastics to flexible resins, our guide highlights key properties like strength, flexibility, and surface finish, helping you choose the right material for prototyping, production, or custom parts.

Tough Resin

Process: SLA

Durability, Strength

3D printing tough resin material is designed for printing projects that require high durability and impact resistance. It offers excellent mechanical properties, capable of withstanding high pressure and severe impact, while maintaining precise printing details. Whether creating prototypes, functional parts, or industrial applications, the tough resin provides an ideal balance—finding the sweet spot between strength and flexibility.

PA+GF

Process: SLS or MJF

Temperature Resistance, Durability, Dimensional Stability

PA+GF is a polyamide powder material reinforced with glass beads, which significantly improves stiffness and dimensional stability. Compared with unfilled polyamide, this material offers higher heat resistance and demonstrates excellent long-term wear performance. However, due to the addition of glass, its impact strength and tensile strength are relatively lower than those of other nylons.

PA-Like

Process: SLS or MJF

Durability, Temperature Resistant

Nylon is a high-performance engineering polymer with well-balanced properties. It offers high strength, excellent toughness, and outstanding wear resistance, along with superior chemical resistance and thermal stability, ensuring reliable performance even under demanding conditions. Thanks to its lightweight and high reliability, nylon materials are widely used in automotive, medical, aerospace, and consumer products, making them an ideal choice for applications requiring both functionality and durability.

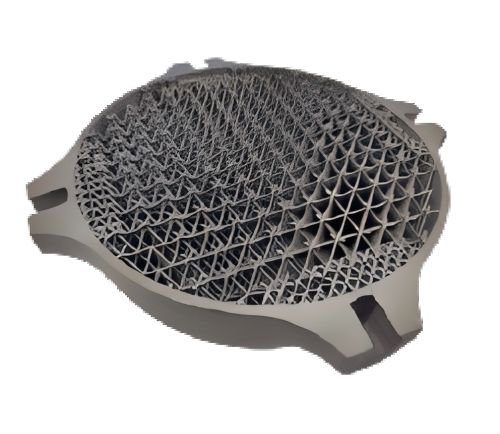

Titanium

Process: SLM

Temperature Resistance, Corrosion Resistance, Strength, Lightweight

3D printed titanium alloys, represented by Ti6Al4V, feature extremely high specific strength and excellent corrosion resistance, while being lightweight and tough. They enable the creation of complex geometries and topology-optimized designs through additive manufacturing, and are widely used in aerospace, medical implants, automotive, and high-performance sports equipment. Titanium alloys also offer good high-temperature performance and biocompatibility, making them an ideal choice for manufacturing high-performance, lightweight components.

Disadvantages: Poor heat resistance (maximum 120°C); surface roughness around Ra10, with slight pits and visible layer texture.Stainless Steel 316L

Process: SLM

Durability, Corrosion Resistance, Strength

Stainless steel 316L offers excellent corrosion resistance and high-temperature performance. It combines good mechanical strength and toughness, making it a reliable material for manufacturing acid- and corrosion-resistant components. Thanks to its outstanding corrosion resistance and its suitability as a medical- and food-grade material, it is widely used in aerospace, prototypes, tooling, and medical applications. Finished parts are typically shot-peened for surface treatment. If you require any other post-processing, please inform our customer service clearly.

Disadvantages: Poor heat resistance (maximum 120°C); surface roughness around Ra10, with slight pits and visible layer texture.Aluminum

Process: SLM

HighStrength, CorrosionResistant, Lightweight

3D printed aluminum alloys, represented by AlSi10Mg and other aluminum-silicon-magnesium alloys, combine lightweight characteristics with excellent mechanical properties. They offer an outstanding strength-to-weight ratio, good corrosion resistance, and thermal conductivity, and demonstrate excellent fatigue and fracture resistance after heat treatment. The material is easy to form, weld, and machine, making it ideal for aerospace, automotive, and tooling applications where lightweight design and structural complexity are critical. Finished parts are typically shot-peened for surface treatment. If you require any other post-processing, please inform our customer service clearly.

Disadvantages: Poor heat resistance (maximum 120°C); surface roughness around Ra10, with slight pits and visible layer texture.