Compare 3D Printing Materials

Explore and compare 3D printing materials to find the best fit for your project. From durable plastics to flexible resins, our guide highlights key properties like strength, flexibility, and surface finish, helping you choose the right material for prototyping, production, or custom parts.

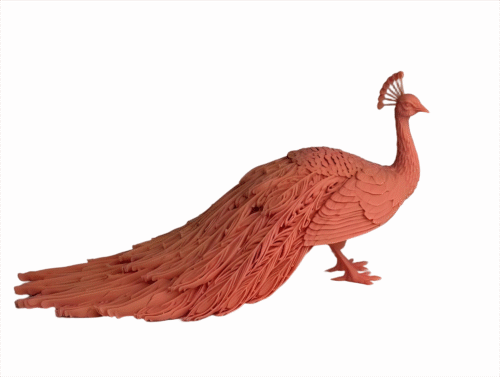

Red wax

Process: DLP

High Precision, Smooth Surface

Wax materials are a special type of material commonly used in 3D printing, primarily applied in rapid prototyping and precision casting. They offer excellent flowability and moldability, allowing for high-precision detail during the printing process. Red wax, in particular, has a vivid color, usually deep red, hence the name “red wax.” One of its key features is its ability to melt quickly when heated, facilitating subsequent casting processes, making it especially suitable for jewelry, art sculptures, and the manufacture of complex mechanical parts.

In addition, red wax materials have moderate hardness and a smooth surface, requiring minimal post-processing after printing, which helps maintain the accuracy and surface quality of the print. Because it can be melted at high temperatures, it is also commonly used in the “lost wax casting” process, playing a crucial role in precision casting.

PLA

Process: FDM

Durability, Biodegradable, RichColors, Economical

PLA is a high-quality, high-performance, and cost-effective 3D printing material, offering excellent layer adhesion and impact resistance, resulting in durable and long-lasting prints. The base series comes in up to 30 colors, ensuring uniform color consistency and stable printing quality. PLA is made from renewable plant-based resources, eco-friendly, non-toxic, and biodegradable. It is reliable, easy to use, and provides high cost-performance with a wide range of colors, making it an ideal choice for home, education, and industrial printing.

PC-Like Translucent

Process: SLA

Transparency, Stiffness

PC-like translucent material combines excellent translucency with high stiffness, making it an ideal choice for precision components. Through customized post-processing, functional light-transmitting effects can be achieved, delivering both aesthetic appeal and performance. With high tensile strength and modulus, this material is especially suited for creating functional prototypes that emulate injection-molded polycarbonate, meeting the dual demands of mechanical performance and visual quality for engineering prototypes and small-batch production.

PC-Like Advanced Temp

Process: SLA

Temperature Resistance, Strength, Stiffness

PC-Like Advanced High Temp is a high-temperature reinforced material with properties similar to polycarbonate, specifically designed for functional parts that require a combination of high strength, stiffness, and heat resistance. Post-curing can further increase the heat deflection temperature of the parts, enhancing their stability and reliability in high-temperature environments. It should be noted that post-curing may reduce some aspects of durability, so a balance between strength and toughness should be considered during design.

Ceramic-Like

Process: SLA

Heat Resistance, Strength, Stiffness

The high-temperature reinforced ceramic white combines exceptional heat resistance with outstanding strength and stiffness, making it an ideal choice for functional parts and high-performance prototypes. Post-curing further enhances its mechanical properties and thermal stability, providing reliable performance for complex geometries. Whether for aerospace, precision molds, electronic insulators, or laboratory equipment, this ceramic material meets the highest standards under demanding conditions, delivering solid support for innovative designs and high-performance manufacturing.

PA+GF

Process: SLS or MJF

Temperature Resistance, Durability, Dimensional Stability

PA+GF is a polyamide powder material reinforced with glass beads, which significantly improves stiffness and dimensional stability. Compared with unfilled polyamide, this material offers higher heat resistance and demonstrates excellent long-term wear performance. However, due to the addition of glass, its impact strength and tensile strength are relatively lower than those of other nylons.

ABS-Like

Process: FDM or SLA

Moisture Resistance, Durability

ABS-like material is a durable and versatile prototyping material suitable for producing both functional and aesthetic parts. Its front surface is smooth, while the side walls and bottom have a matte finish, giving parts an appearance similar to injection-molded components. The material offers good dimensional stability, moisture resistance, and is easy to post-process, making it ideal for rapid prototyping and functional testing.It is usually available in black and white.