Comparison of CNC Machining Materials

The information contained herein is typical values intended for reference and comparison only. They shall NOT be used as a basis for design specifications or quality control.

CPVC

Temperature Resistant, Flame Retardancy

CPVC (Chlorinated Polyvinyl Chloride) is a thermoplastic plastic obtained by chlorination modification of polyvinyl chloride (PVC). Such structural changes enable it to far outperform ordinary PVC in terms of heat resistance, mechanical properties, and chemical resistance, making it an ideal material for high-temperature and corrosive environments.

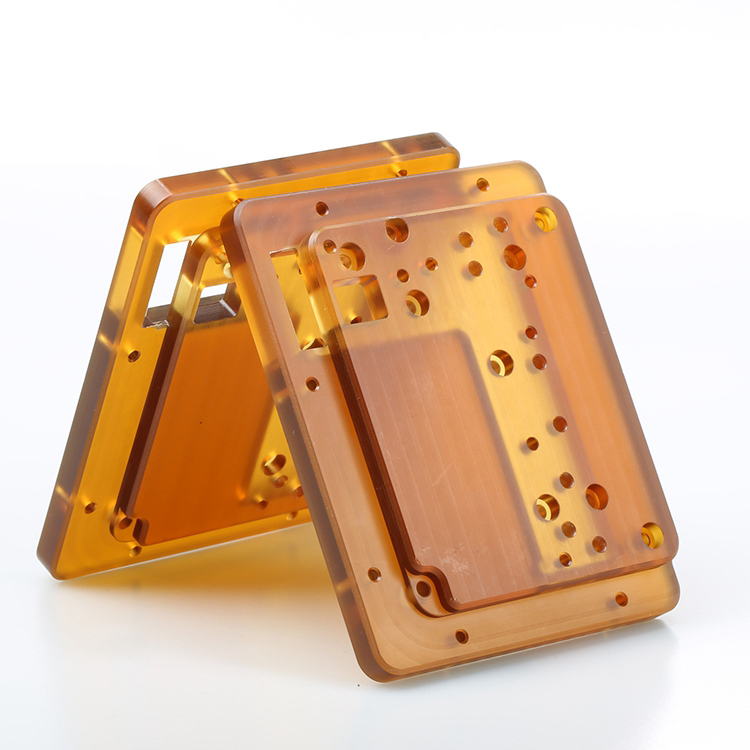

PEI

Temperature Resistance, Strength, CorrosionResistant, Flame Retardancy, Electrical Insulation, Aging Resistance

PEI (polyetherimide) is a high-performance thermoplastic engineering plastic that combines excellent heat resistance, mechanical properties, and chemical stability, enabling it to be widely used in high-end industrial fields such as aerospace, electronics and electrical engineering, and medical equipment.

PP

Corrosion Resistant, Strength

Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

PVC

Economical, Weather Resistance, Flame Retardancy

Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as construction, industry, packaging, and healthcare.

PEEK

Corrosion Resistance, Strength, Temperature Resistant

PEEK (Polyetheretherketone) is a top-performing thermoplastic engineering plastic, featuring excellent high-temperature resistance, robust mechanical properties, versatile corrosion resistance, top-tier biocompatibility, exceptional dimensional stability, and outstanding electrical insulation and radiation resistance. It is widely used in high-end fields such as aerospace, high-end medical care, and electronic semiconductors.

Stainless Steel 304

Corrosion Resistant, Economical, Machinability

stainless steel 304 is also known as 18/8 stainless steel, which contains approximately 18% chromium (Cr) and 8% nickel (Ni). It not only possesses excellent oxidation resistance and corrosion resistance, but also has good workability and surface quality. Currently, it is the most widely used stainless steel grade in industrial manufacturing and civil applications.

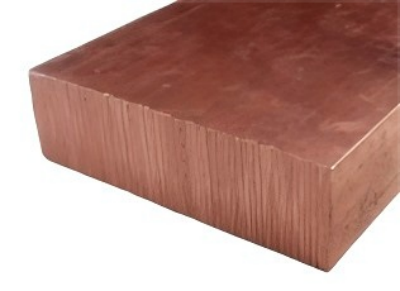

Copper C101

Durability, Thermal Conductivity, Conductivity

C101 copper, also known as HC copper (High Conductivity Copper) or more precisely, high-conductivity copper, has a nominal electrical conductivity of 100% IACS (International Annealed Copper Standard)—a benchmark level for conductive performance. It also features excellent high thermal conductivity, making it the preferred material for various electrical components (such as terminals) and conductors (such as power transmission busbars).

Furthermore, this material possesses high ductility (enabling easy complex forming processes like stretching and bending) and reliable impact resistance. While meeting the requirements for electrical performance, it can also accommodate the structural stability demands of mechanical processing and practical operating conditions, making it truly a high-quality copper material that combines multi-functional properties with practical value.