Comparison of CNC Machining Materials

The information contained herein is typical values intended for reference and comparison only. They shall NOT be used as a basis for design specifications or quality control.

CPVC

Temperature Resistant, Flame Retardancy

CPVC (Chlorinated Polyvinyl Chloride) is a thermoplastic plastic obtained by chlorination modification of polyvinyl chloride (PVC). Such structural changes enable it to far outperform ordinary PVC in terms of heat resistance, mechanical properties, and chemical resistance, making it an ideal material for high-temperature and corrosive environments.

HIPS

Impact Resistance, Economical, Electrical Insulation

High Impact Polystyrene (HIPS) is a low-cost and easily processable plastic material. It is often used in the manufacturing of low-strength structural components in scenarios where comprehensive requirements for a material’s impact resistance, processability, and cost are required. Additionally, with its excellent dimensional stability and ease of being painted and bonded, it has become an ideal material for prototyping.

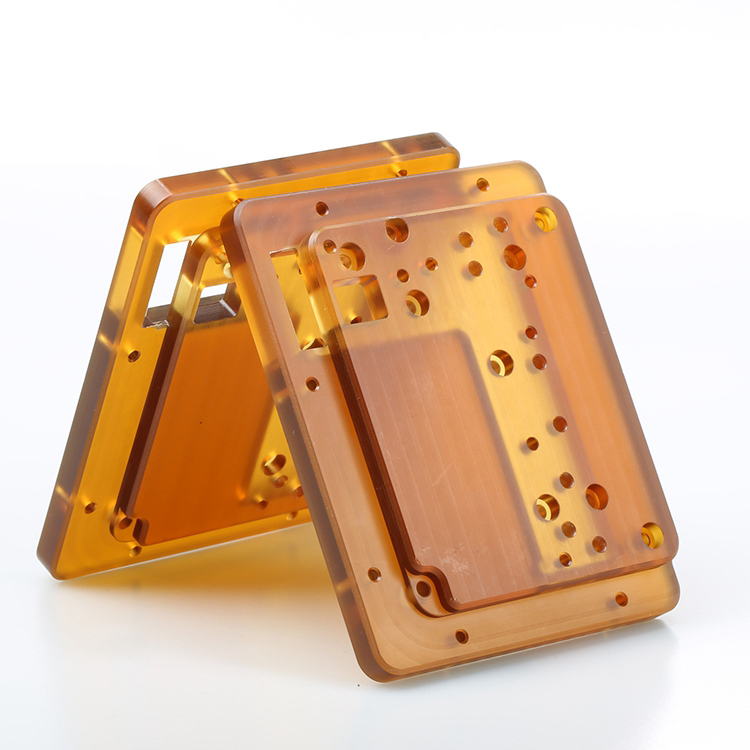

PEI

Temperature Resistance, Strength, CorrosionResistant, Flame Retardancy, Electrical Insulation, Aging Resistance

PEI (polyetherimide) is a high-performance thermoplastic engineering plastic that combines excellent heat resistance, mechanical properties, and chemical stability, enabling it to be widely used in high-end industrial fields such as aerospace, electronics and electrical engineering, and medical equipment.

PVC

Economical, Weather Resistance, Flame Retardancy

Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as construction, industry, packaging, and healthcare.

ABS

Strength, Economical, Processability

ABS (Acrylonitrile-Butadiene-Styrene Copolymer) is a well-balanced engineering plastic with good mechanical properties, excellent impact resistance, and easy processability. These characteristics have led to its widespread application in fields such as consumer electronics, household appliances, automotive industry, and daily necessities.

Titanium

Heat Resistance, Corrosion Resistance, Strength

Titanium alloys are high-performance materials that combine exceptional strength, a superior strength-to-weight ratio, outstanding corrosion resistance, high-temperature stability, and excellent biocompatibility. While costlier and more difficult to process than steels or aluminum alloys, their unique advantages—high strength, light weight, and durability in extreme environments—make them indispensable in aerospace, advanced medical, and deep-sea applications, where performance takes priority over cost.

Steel Alloy 4140

Impact Resistance, Fatigue Resistant

AISI 4140 Alloy Steel is a medium-carbon chromium-molybdenum steel with a carbon content of about 0.38–0.43%. It offers an excellent combination of strength, toughness, wear resistance, and machinability. When heat-treated, it provides outstanding mechanical properties, making it widely used in gears, crankshafts, connecting rods, bolts, and critical components in the oil and gas industry.

Stainless Steel 304

Corrosion Resistant, Economical, Machinability

stainless steel 304 is also known as 18/8 stainless steel, which contains approximately 18% chromium (Cr) and 8% nickel (Ni). It not only possesses excellent oxidation resistance and corrosion resistance, but also has good workability and surface quality. Currently, it is the most widely used stainless steel grade in industrial manufacturing and civil applications.

Low Carbon Steel

Economical, Machinability

Low carbon steel (with carbon content not exceeding 0.25%) is one of the most commonly used types of steel in both industry and daily life, thanks to its excellent plasticity, weldability, and low cost. It is widely applied in components such as pistons, screws, and drive shafts. However, due to its limited strength, it usually requires post-treatment.

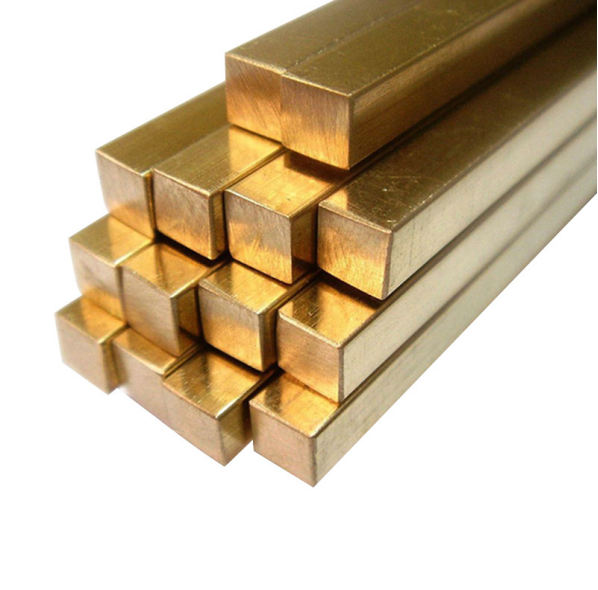

Brass C260

CorrosionResistant, Machinability

Brass is an alloy primarily composed of copper and zinc. This golden-hued material not only exhibits excellent weather resistance and corrosion resistance, but its tensile strength also rivals that of low-carbon steel, demonstrating outstanding mechanical properties. Brass boasts exceptional machinability, enabling it to support higher feed rates during processing operations such as cutting and stamping, while requiring minimal cutting fluid. This combination significantly reduces both processing costs and process complexity.