Comparison of CNC Machining Materials

The information contained herein is typical values intended for reference and comparison only. They shall NOT be used as a basis for design specifications or quality control.

CPVC

Temperature Resistant, Flame Retardancy

CPVC (Chlorinated Polyvinyl Chloride) is a thermoplastic plastic obtained by chlorination modification of polyvinyl chloride (PVC). Such structural changes enable it to far outperform ordinary PVC in terms of heat resistance, mechanical properties, and chemical resistance, making it an ideal material for high-temperature and corrosive environments.

HIPS

Impact Resistance, Economical, Electrical Insulation

High Impact Polystyrene (HIPS) is a low-cost and easily processable plastic material. It is often used in the manufacturing of low-strength structural components in scenarios where comprehensive requirements for a material’s impact resistance, processability, and cost are required. Additionally, with its excellent dimensional stability and ease of being painted and bonded, it has become an ideal material for prototyping.

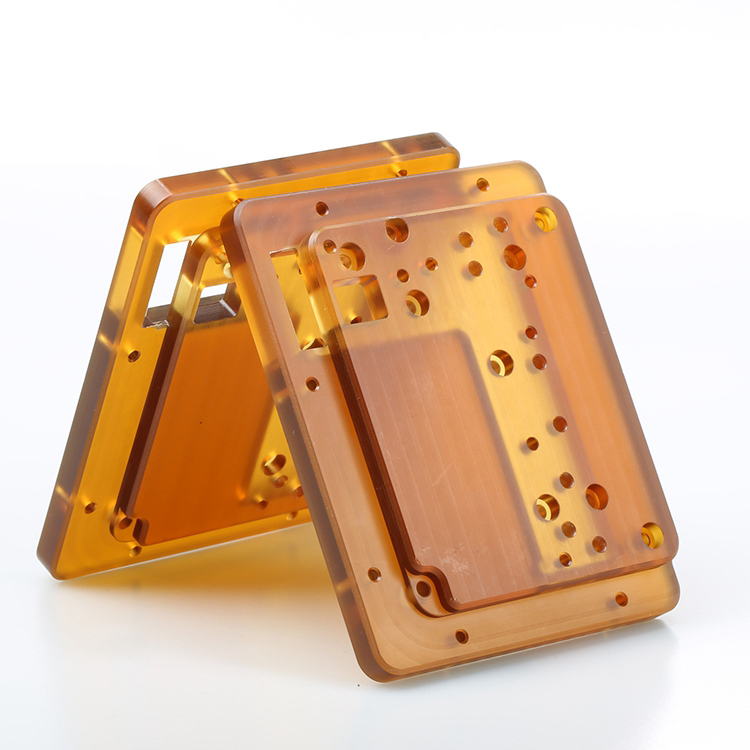

PEI

Temperature Resistance, Strength, CorrosionResistant, Flame Retardancy, Electrical Insulation, Aging Resistance

PEI (polyetherimide) is a high-performance thermoplastic engineering plastic that combines excellent heat resistance, mechanical properties, and chemical stability, enabling it to be widely used in high-end industrial fields such as aerospace, electronics and electrical engineering, and medical equipment.

LDPE

Corrosion Resistance, Toughness, Electrical Insulation

Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

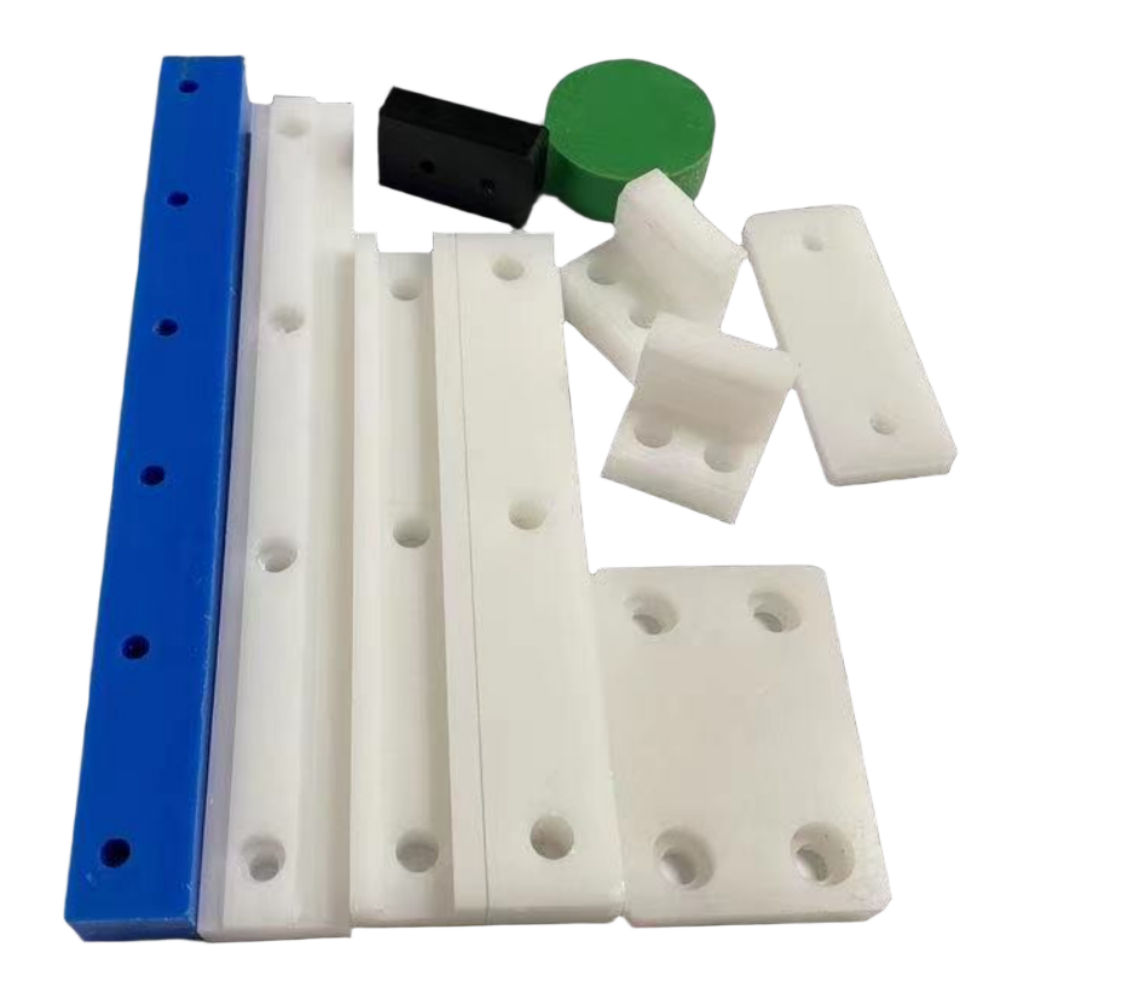

HDPE

Corrosion Resistance, Strength, Electrical Insulation

High-Density Polyethylene (HDPE) is a lightweight, chemically resistant, and high-strength material. It is flexible and tough, commonly used in applications such as food packaging (e.g., food containers), agricultural films, daily necessities (e.g., storage boxes), and water tanks.

PET

Corrosion Resistance, Strength, High Transparency, Processability

PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PVC

Economical, Weather Resistance, Flame Retardancy

Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as construction, industry, packaging, and healthcare.

PMMA (Acrylic)

Impact Resistance, High Transparency, Weather Resistance

Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical lenses and stage light covers.

PEEK

Corrosion Resistance, Strength, Temperature Resistant

PEEK (Polyetheretherketone) is a top-performing thermoplastic engineering plastic, featuring excellent high-temperature resistance, robust mechanical properties, versatile corrosion resistance, top-tier biocompatibility, exceptional dimensional stability, and outstanding electrical insulation and radiation resistance. It is widely used in high-end fields such as aerospace, high-end medical care, and electronic semiconductors.