Comparison of CNC Machining Materials

The information contained herein is typical values intended for reference and comparison only. They shall NOT be used as a basis for design specifications or quality control.

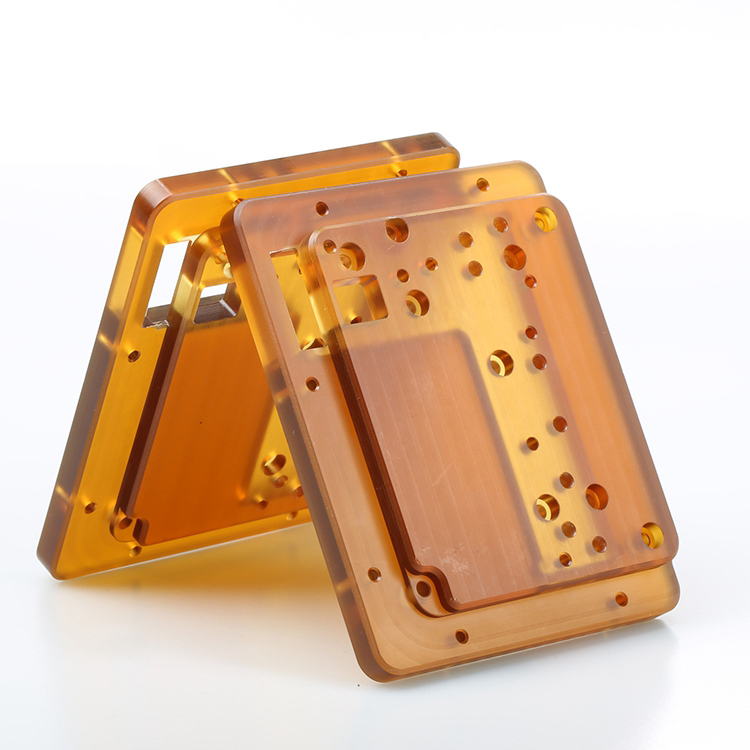

PEI

Temperature Resistance, Strength, CorrosionResistant, Flame Retardancy, Electrical Insulation, Aging Resistance

PEI (polyetherimide) is a high-performance thermoplastic engineering plastic that combines excellent heat resistance, mechanical properties, and chemical stability, enabling it to be widely used in high-end industrial fields such as aerospace, electronics and electrical engineering, and medical equipment.

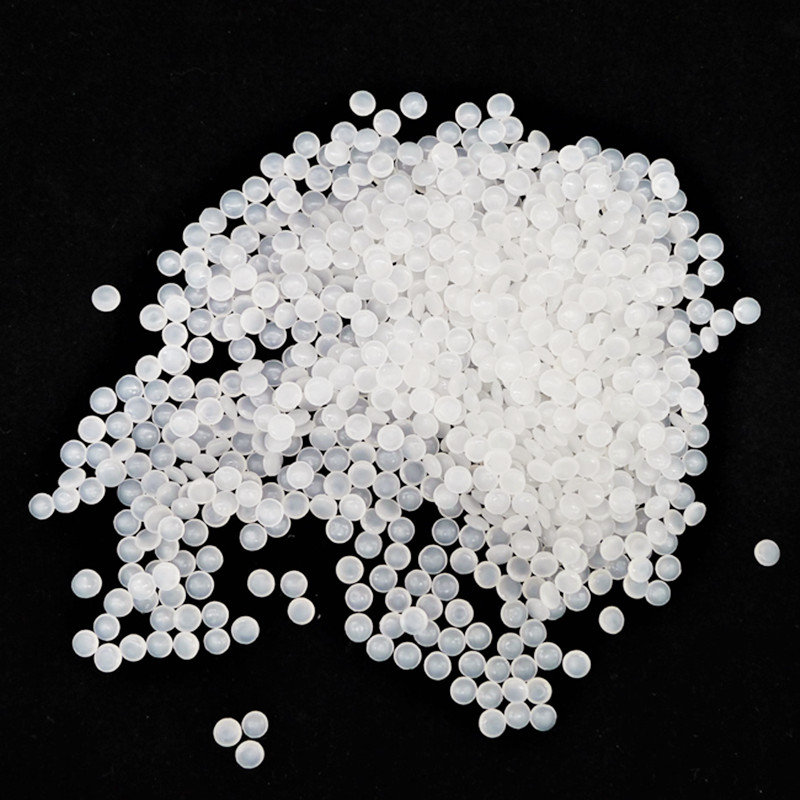

LDPE

Corrosion Resistance, Toughness, Electrical Insulation

Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

Low Carbon Steel

Economical, Machinability

Low carbon steel (with carbon content not exceeding 0.25%) is one of the most commonly used types of steel in both industry and daily life, thanks to its excellent plasticity, weldability, and low cost. It is widely applied in components such as pistons, screws, and drive shafts. However, due to its limited strength, it usually requires post-treatment.