Injection Molding Materials

Choosing the right injection molding material can make or break your project. Our comprehensive guide helps you quickly compare options based on strength, flexibility, and heat resistance, so you can confidently select the ideal material for prototypes, production parts, or custom designs—ensuring high-quality results every time.

PC+GF

Type: PC+GF

Impact Resistance, Strength, Aging Resistance

PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making it suitable for scenarios with high requirements for strength, rigidity, and dimensional accuracy. It features high strength, high rigidity, and heat resistance, and is ideal for automotive parts, electrical enclosures, and structural components.

TPU

Type: TPU

Impact Resistance, Wear Resistant, Chemical Resistant, Aging Resistance

TPU (Thermoplastic Polyurethane), commonly known as urethane rubber, is a thermoplastic elastomer. It features excellent elasticity, abrasion resistance, and chemical corrosion resistance, and is widely used in applications such as mobile phone cases (soft shells), sports shoe soles, and medical catheters.

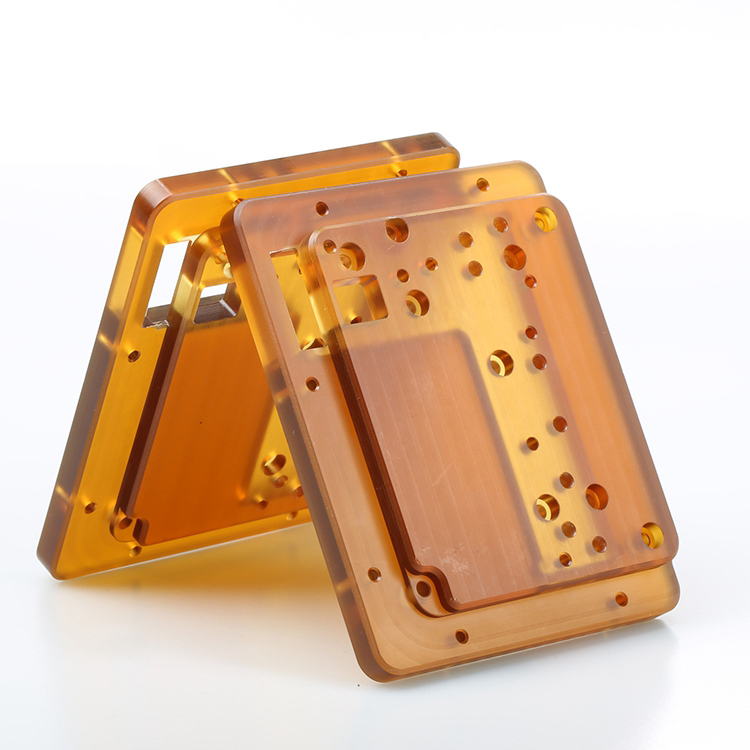

PC+GF

Type: PC+GF

Impact Resistance, Strength, Aging Resistance

PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making it suitable for scenarios with high requirements for strength, rigidity, and dimensional accuracy. It features high strength, high rigidity, and heat resistance, and is ideal for automotive parts, electrical enclosures, and structural components.

PEI

Type: PEI

Temperature Resistance, Strength, CorrosionResistant, Flame Retardancy, Electrical Insulation, Aging Resistance

PEI (polyetherimide) is a high-performance thermoplastic engineering plastic that combines excellent heat resistance, mechanical properties, and chemical stability, enabling it to be widely used in high-end industrial fields such as aerospace, electronics and electrical engineering, and medical equipment.

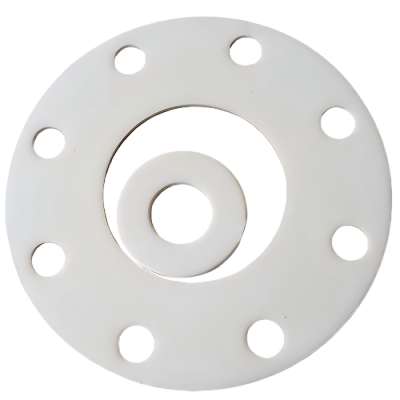

PTFE

Type: PTFE

Temperature Resistance, Corrosion Resistance, low friction Coefficient, Aging Resistance

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer. It is frequently used in mechanical components requiring reduced friction and wear—such as bearings, gears, and piston rings—due to its non-stick properties, low friction characteristics, and self-lubricating capabilities. PTFE also exhibits excellent electrical insulation properties, making it highly suitable for applications like high-frequency cables, high-voltage insulators, and electronic components.

Additionally, PTFE maintains stable performance during long-term use across an extreme temperature range from -200°C (ultra-low temperature) to 260°C (high temperature), enabling its use in harsh environments such as aerospace systems, deep-sea equipment, and high-temperature industrial apparatus.

PP

Type: PP

Corrosion Resistant, Strength

Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

PVC

Type: PVC

Economical, Weather Resistance, Flame Retardancy

Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as construction, industry, packaging, and healthcare.

PMMA (Acrylic)

Type: PMMA (Acrylic)

Impact Resistance, High Transparency, Weather Resistance

Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical lenses and stage light covers.

PEEK

Type: PEEK

Impact Resistance, Chemical Resistant, Food Grade, High Temp, Sterilizable

PEEK (Polyetheretherketone) is a top-performing thermoplastic engineering plastic, featuring excellent high-temperature resistance, robust mechanical properties, versatile corrosion resistance, top-tier biocompatibility, exceptional dimensional stability, and outstanding electrical insulation and radiation resistance. It is widely used in high-end fields such as aerospace, high-end medical care, and electronic semiconductors.

TPU

Type: TPU

Impact Resistance, Wear Resistance, Chemical Resistant, Aging Resistance

TPU (Thermoplastic Polyurethane), commonly known as urethane rubber, is a thermoplastic elastomer. It features excellent elasticity, abrasion resistance, and chemical corrosion resistance, and is widely used in applications such as mobile phone cases (soft shells), sports shoe soles, and medical catheters.