Injection Molding Materials

Choosing the right injection molding material can make or break your project. Our comprehensive guide helps you quickly compare options based on strength, flexibility, and heat resistance, so you can confidently select the ideal material for prototypes, production parts, or custom designs—ensuring high-quality results every time.

PC+ABS

Type: PC+ABS

Impact Resistance, Strength

PC+ABS is a blend-modified material that combines the advantages of both materials. It not only inherits the high impact resistance of PC but also the material strength of ABS, while improving its heat resistance. It is often used in electronic product casings, automotive interiors, consumer products, and more.

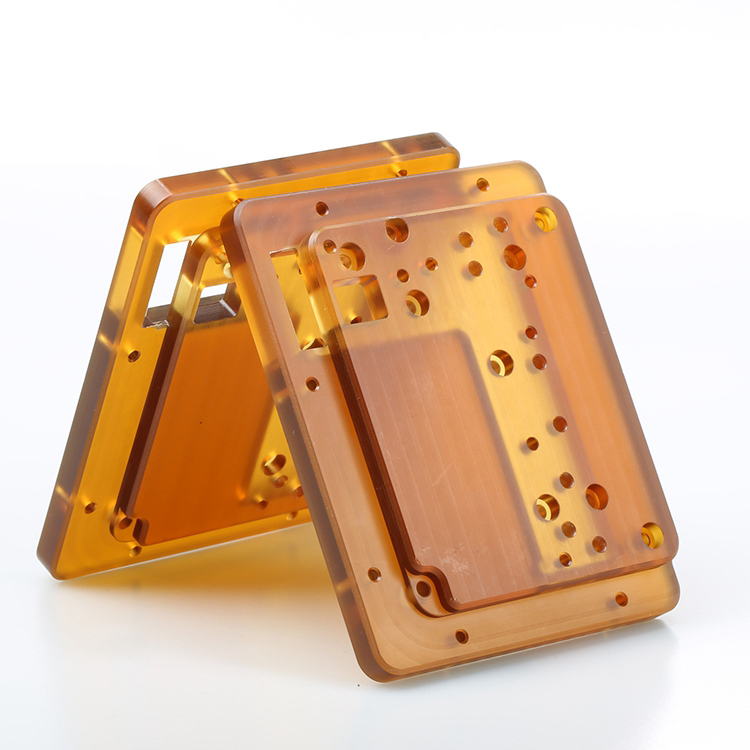

PEI

Type: PEI

Temperature Resistance, Strength, CorrosionResistant, Flame Retardancy, Electrical Insulation, Aging Resistance

PEI (polyetherimide) is a high-performance thermoplastic engineering plastic that combines excellent heat resistance, mechanical properties, and chemical stability, enabling it to be widely used in high-end industrial fields such as aerospace, electronics and electrical engineering, and medical equipment.

PP

Type: PP

Corrosion Resistant, Strength

Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.