Injection Molding Materials

Choosing the right injection molding material can make or break your project. Our comprehensive guide helps you quickly compare options based on strength, flexibility, and heat resistance, so you can confidently select the ideal material for prototypes, production parts, or custom designs—ensuring high-quality results every time.

HIPS

Type: HIPS

Impact Resistance, Economical, Electrical Insulation

High Impact Polystyrene (HIPS) is a low-cost and easily processable plastic material. It is often used in the manufacturing of low-strength structural components in scenarios where comprehensive requirements for a material’s impact resistance, processability, and cost are required. Additionally, with its excellent dimensional stability and ease of being painted and bonded, it has become an ideal material for prototyping.

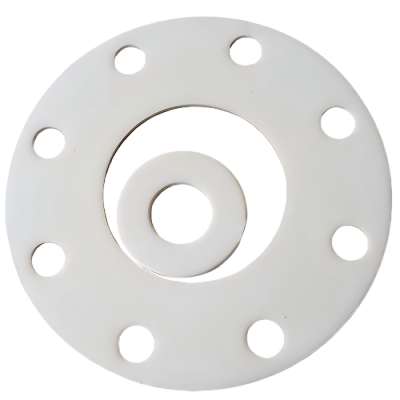

PTFE

Type: PTFE

Temperature Resistance, Corrosion Resistance, low friction Coefficient, Aging Resistance

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer. It is frequently used in mechanical components requiring reduced friction and wear—such as bearings, gears, and piston rings—due to its non-stick properties, low friction characteristics, and self-lubricating capabilities. PTFE also exhibits excellent electrical insulation properties, making it highly suitable for applications like high-frequency cables, high-voltage insulators, and electronic components.

Additionally, PTFE maintains stable performance during long-term use across an extreme temperature range from -200°C (ultra-low temperature) to 260°C (high temperature), enabling its use in harsh environments such as aerospace systems, deep-sea equipment, and high-temperature industrial apparatus.

PET

Type: PET

Corrosion Resistance, Strength, High Transparency, Processability

PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.