Injection Molding Materials

Choosing the right injection molding material can make or break your project. Our comprehensive guide helps you quickly compare options based on strength, flexibility, and heat resistance, so you can confidently select the ideal material for prototypes, production parts, or custom designs—ensuring high-quality results every time.

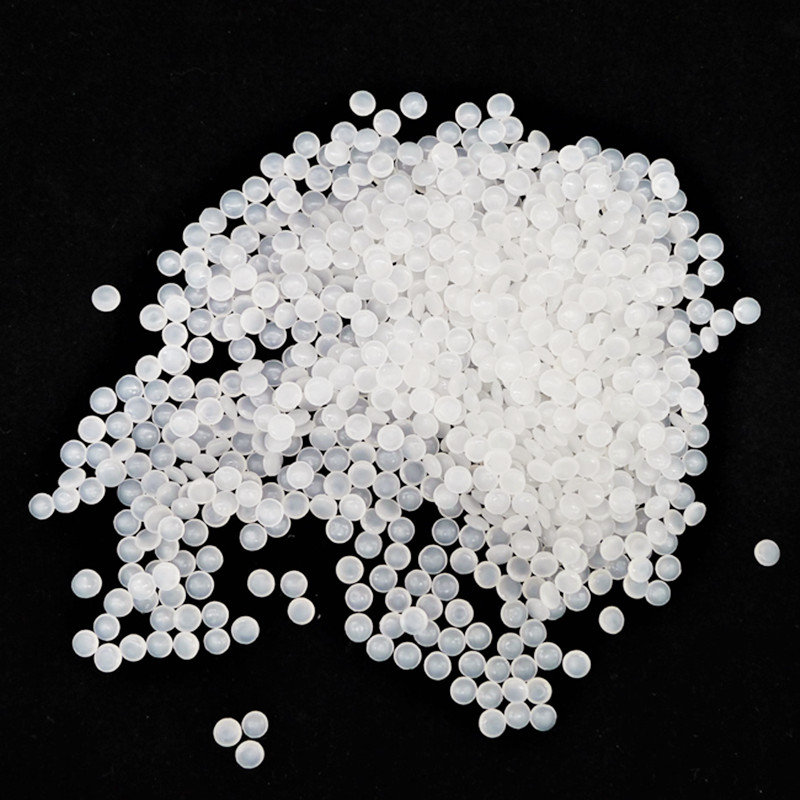

LDPE

Type: LDPE

Corrosion Resistance, Toughness, Electrical Insulation

Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PA (Nylon)

Type: PA (Nylon)

Wear Resistance, Strength, Chemical Resistant, Self-lubrication

Nylon is a versatile and widely used material in CNC machining due to its exceptional properties. Its high tensile strength, low coefficient of friction, and resistance to wear and abrasion make it an excellent choice for applications requiring durability and reliability, such as gears, bushings, and bearings. Additionally, nylon’s low moisture absorption and good dimensional stability ensure consistent performance even in humid or varying temperature conditions.

Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications in the automotive, aerospace, and medical industries. With its remarkable combination of properties, nylon stands out as a versatile and reliable material for a diverse range of CNC machining applications.

POM (Delrin)

Type: POM (Delrin)

Impact Resistance, Chemical Resistant

Polyoxymethylene (POM) is a premium high-performance engineering plastic. Known for its metal-like mechanical strength, it offers exceptional hardness, rigidity, impact and fatigue resistance, as well as outstanding wear resistance and self-lubrication. POM also provides excellent dimensional stability, strong chemical resistance, and ease of processing. With this unique combination of properties, it has become a preferred material across industries such as machinery, automotive, electronics, and medical devices—making it an ideal replacement for metal in manufacturing high-precision, wear-resistant components.