Injection Molding Materials

Choosing the right injection molding material can make or break your project. Our comprehensive guide helps you quickly compare options based on strength, flexibility, and heat resistance, so you can confidently select the ideal material for prototypes, production parts, or custom designs—ensuring high-quality results every time.

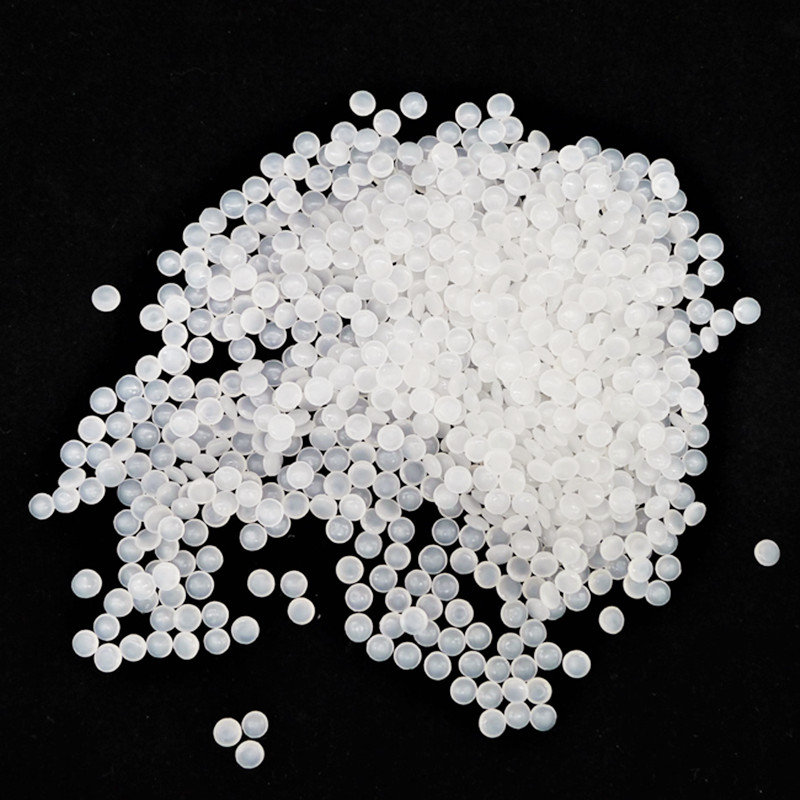

LDPE

Type: LDPE

Corrosion Resistance, Toughness, Electrical Insulation

Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PET

Type: PET

Corrosion Resistance, Strength, High Transparency, Processability

PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PC

Type: PC

Impact Resistance, Processability

PC (polycarbonate, commonly known as bulletproof glue) is inherently pale yellow or colorless and transparent, featuring hardness, toughness and luster. It boasts prominent advantages: with a light transmittance of 90%, it not only has good mechanical strength but also excellent impact resistance, along with outstanding heat resistance and weatherability.