Sheet Metal Materials

Compare sheet metal materials to find the ideal solution for your project. From steel and aluminum to specialty alloys, our guide highlights key properties like strength, durability, and flexibility, helping you choose the right material for prototypes, production parts, or custom designs.

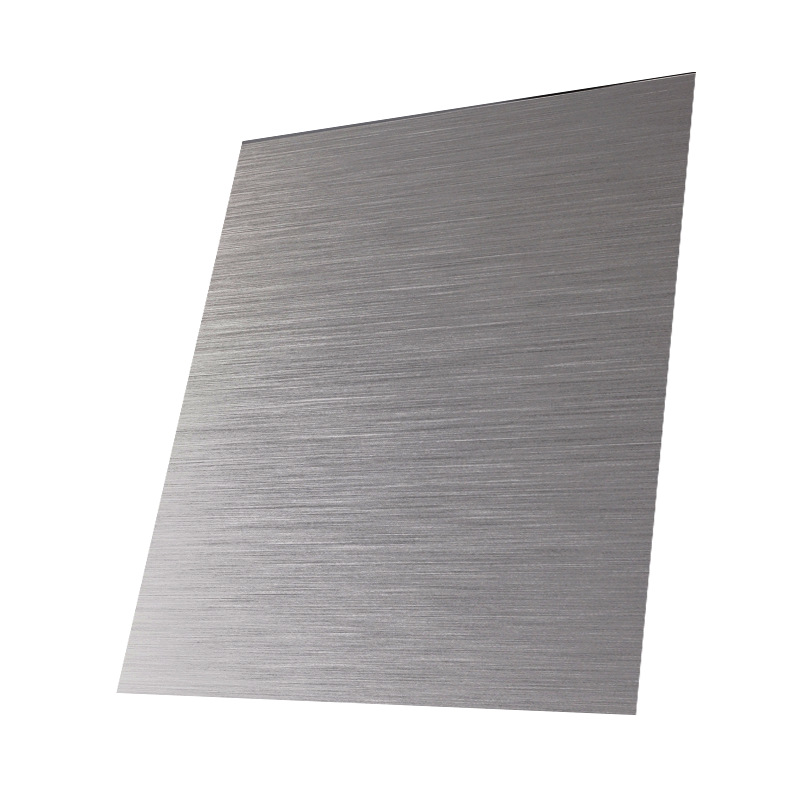

Stainless steel 316 sheet is an austenitic stainless steel containing molybdenum, which gives it superior corrosion resistance compared to 304, especially in chloride environments. The 316 stainless steel sheet not only offers excellent resistance to acids, alkalis, and pitting corrosion, but also has good toughness and weldability, making it resistant to cracking or deformation during processing. With a smooth and attractive surface that is easy to clean and maintain, it is ideal for use in chemical equipment, ships, medical devices, marine facilities, and high-end kitchen equipment where high corrosion resistance is required.

Galvanized steel comes with a zinc coating that provides both corrosion resistance and an attractive appearance. Thanks to its excellent workability, the surface zinc layer is not easily cracked or peeled during forming and processing. Although part of the zinc layer may vaporize during welding, the remaining zinc still offers localized corrosion protection.

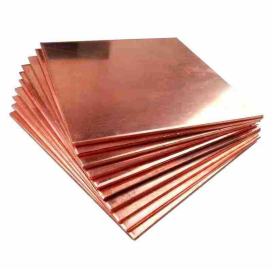

The core advantage of copper materials lies in their exceptional electrical and thermal conductivity, combined with excellent corrosion resistance, malleability, and ductility. This allows copper to be easily fabricated into a wide range of complex shapes, making it highly valuable across multiple industries.

C101 (commonly known as oxygen-free electronic copper) contains virtually no oxygen impurities, offering top-tier purity and conductivity. It is the preferred material for applications with extremely high requirements for material purity and electrical efficiency. However, its cost is higher than C110, making it more suitable for scenarios where peak conductivity is critical and cost is not the primary concern, such as high-precision electronic components and key conductive parts.

C110, an oxygen-containing derivative of C101, contains only trace amounts of oxygen. While its purity, conductivity, and corrosion resistance are slightly lower than C101, it still meets the core requirements of most industrial applications. With lower cost and excellent formability, C110 is commonly used in heat exchangers, industrial wiring, and piping systems.

Aluminum 6061 is a high-strength alloy belonging to the Al-Mg-Si series. Compared with Aluminum 5052, it offers significantly higher strength, making it highly suitable for load-bearing and structural applications. For this reason, it is often referred to as “structural aluminum.”

Although 6061 has a lower modulus of elasticity, which means its formability and weldability are not as strong as 5052, it still retains the lightweight characteristics of aluminum alloys, making it popular across various industries. Designed with strength as its primary focus, 6061 is widely used in aerospace, automotive, and industrial components, where durability and high performance are critical.

Aluminum 5052 is a lightweight, high-strength alloy with outstanding corrosion resistance. Its excellent formability and weldability make it ideal for complex shapes and durable parts, even in harsh environments. Combining performance with aesthetic appeal, 5052 is a trusted choice for marine, automotive, industrial, and architectural applications.