Innovative Companies We Support

CNC Turning Manufacturing for Every Stage

CNC Turning

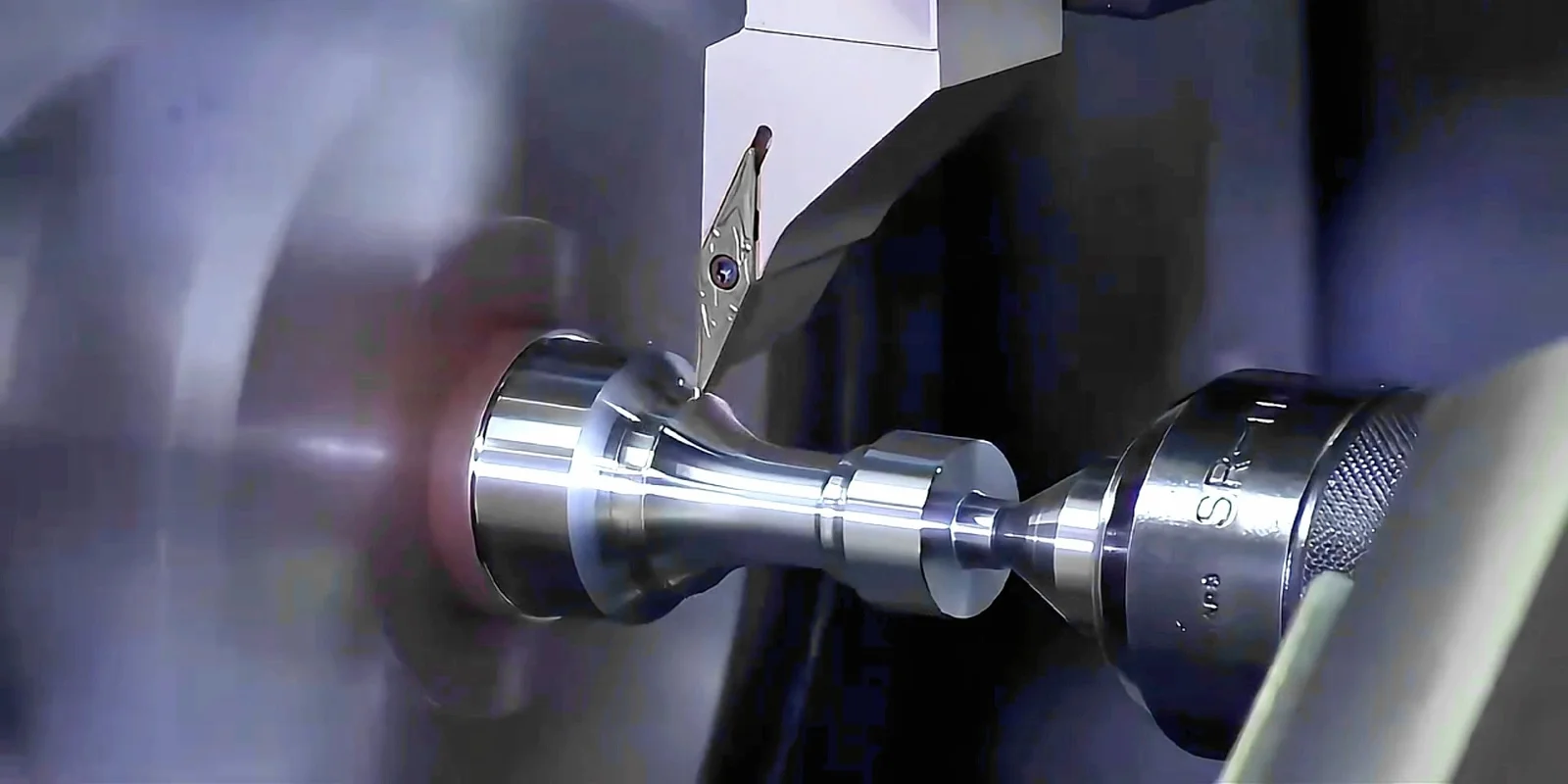

CNC Turning refers to an automated precision manufacturing process in which a computer numerical control (CNC) system is programmed to drive the lathe spindle, rotating the workpiece while controlling the cutting tool to move along a predetermined path. This process performs cutting operations such as external cylindrical surfaces, internal holes, threads, and end faces on rotary parts.

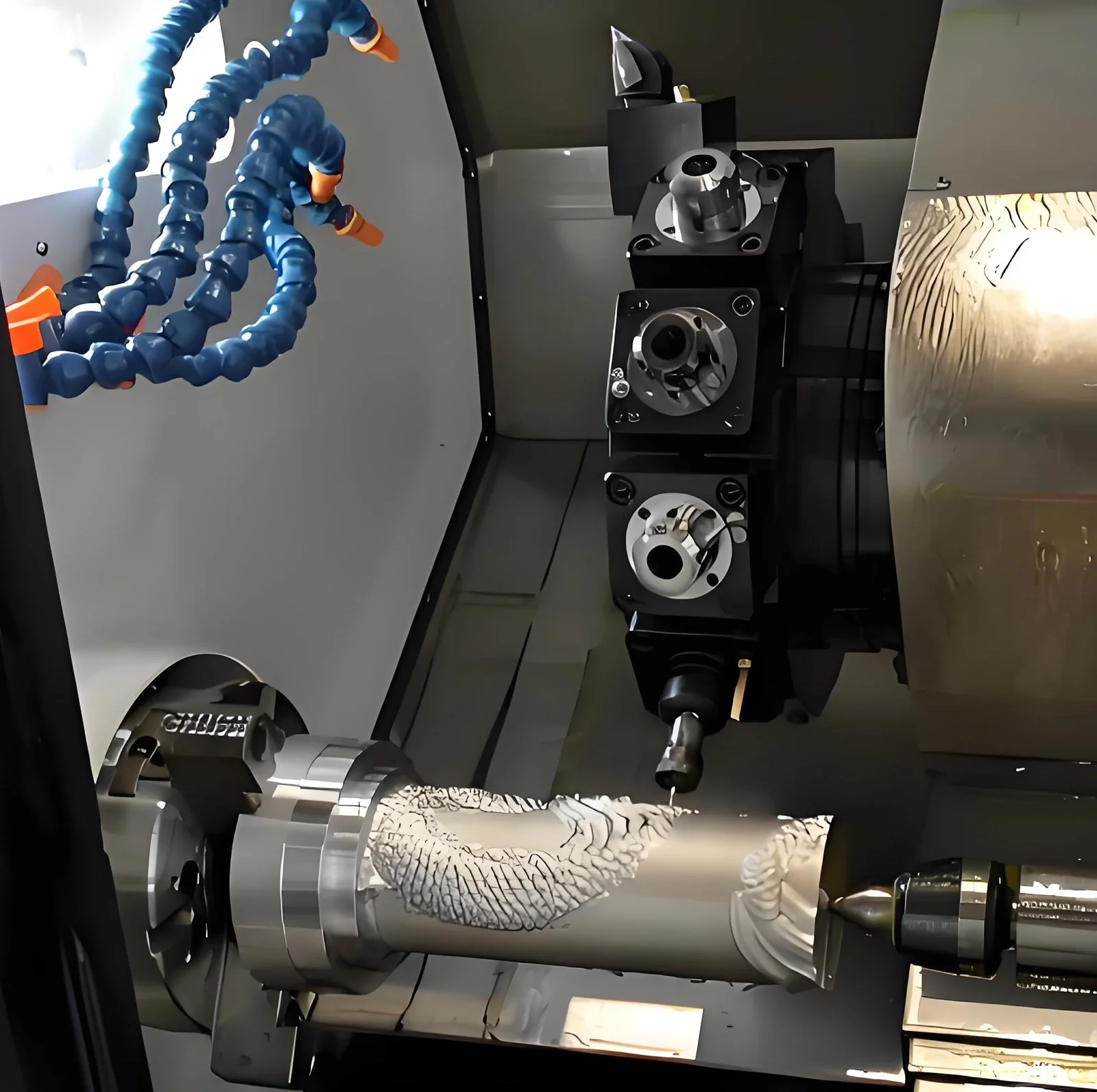

CNC Turning-Milling

CNC Turning-Milling is a hybrid machining process that combines turning and milling operations in a single setup. It enables the efficient production of complex parts with both rotational and non-rotational features, reducing multiple setups while ensuring high precision and consistency. Ideal for intricate geometries, this process enhances productivity and shortens lead times.

Flexible CNC Turning Solutions

Our advanced online CNC turning services offer the flexibility to meet your design needs and development timelines. We produce prototypes, test parts, and low-volume production runs with the speed and accuracy needed for modern product development.

Rapid Prototyping CNC Turning

With Horizon’s custom CNC turning services, you can quickly transform your designs into high-precision, functional prototype parts, enabling design validation, testing, and iterative optimization, and accelerating development to fully prepare for mass production.

Low Volume CNC Turning

Our low-volume turning services deliver precision parts quickly and cost-effectively. With flexible production, rapid turnaround, and no tooling costs, we help you validate designs, bridge to full production, or fulfill small-batch orders with consistent quality.

Why Choose Horizon?

We not only boast advanced turning equipment and years of professional experience in turning, but also have over 50 cooperative partners. This enables us to seamlessly support every stage, from rapid prototyping and small-batch trial production to large-scale mass production.

I

Outstanding CNC turning capability

Horizon boasts not only advanced turning equipment but also a network of over 50 partners—including those with advanced multi-axis CNC lathes. What’s more, custom turned parts can be produced in as little as 1 day.

II

Experienced CNC Engineers

Our expert team specializes in CNC turning, with extensive expertise in DFM validation, material selection, and producing complex geometries. From part analysis and drawing review to precision CNC turning, we guide you through every step, ensuring seamless communication and exceptional results.

III

End-to-End Precision CNC Turning Solutions

Built on years of professional accumulation in the field of turning, we can precisely bridge the gap between design and delivery throughout the entire process from prototype development to mass production. With a rigorous management system, we not only precisely control tolerance accuracy and ensure consistent part quality across all production stages, but also significantly accelerate product development cycles.

IV

With over 50 trusted partners, we cater to both prototypes and mass production, offering cost-effective pricing while ensuring tighter tolerance control. We also provide smoother surface finishes, with additional options such as shot peening and anodizing, and fully support custom requirements.

We offer comprehensive custom cnc turning services, ranging from prototypes delivered in as fast as one day to high-volume production of complex parts, all executed efficiently. With our strong machining capabilities and extensive manufacturing network, we can accommodate larger sizes, higher complexity, and stricter tolerances, providing reliable solutions for our clients.

CNC Turning Materials

Our CNC turning services cover a wide range of metals and engineering plastics. Whether you need precision turning for aluminum components or other materials, we deliver high-quality, accurate parts for industries such as automotive, aerospace, and medical devices. If your project requires specific materials, simply contact us—our experts will evaluate your needs and provide the best material and machining solution.

Metal

Inconel

Inconel Superalloy Materials Inconel alloys are a family of high-performance nickel-chromium superalloys known for their exceptional strength, oxidation resistance, and high-temperature stability. These alloys are widely used in extreme environments where components are subjected to high temperatures, pressure, or mechanical loads.

Magnesium

Magnesium & Magnesium Alloy Materials Magnesium (Mg) and its alloys are among the lightest structural metals available, offering exceptional strength-to-weight ratio, good thermal conductivity, and beneficial vibration-damping properties. These materials are increasingly attractive for advanced engineering uses such as aerospace, automotive, and electronics applications where weight reduction is critical.

Titanium

Titanium Titanium is a lightweight yet high-strength metal known for its exceptional strength-to-weight ratio, excellent corrosion resistance, and outstanding biocompatibility. It maintains stable mechanical properties across high and low temperatures and features a low thermal expansion coefficient, making it ideal for demanding applications. Thanks to these superior properties, titanium and titanium alloys are widely used

Steel Mild Low Carbon

Low-Carbon (Mild) Steel Material Low-carbon steel is a type of carbon steel with low carbon content, typically referring to steel materials with a carbon content ranging from 0.02% to 0.30%. Due to its low carbon content, it is also known as “mild steel.” Its performance characteristics are particularly notable: compared to medium-carbon steel and high-carbon

Stainless Steel

Stainless Steel Material & Alloys Stainless steel is a family of corrosion-resistant iron alloys developed to withstand oxidation, corrosion, and wear. Thanks to its excellent durability, mechanical strength, and versatile formability, stainless steel is widely used across industries requiring long-term performance—even in harsh or aggressive environments. Its favorable operational and welding properties can fully meet

Copper

Copper Material & Copper Alloys Copper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile. Its glossy orange-red appearance is instantly recognizable, and the metal remains aesthetically appealing even during its natural oxidation process—where environmental reactions form a bluish-green coating known as patina. However, it should be noted that copper’s weldability is

Brass

Brass Material & Brass Alloys Explore HorizonRP’s brass materials—offering excellent machinability, corrosion resistance, and attractive appearance. Ideal for hardware, plumbing, decorative, electrical, and industrial applications. Brass is an alloy composed of copper and zinc, with a golden color and excellent weather and corrosion resistance. Its tensile strength is comparable to that of mild steel. In

Aluminum

Aluminum Material & Aluminum Alloys Aluminum is highly favored in CNC machining due to its low density, excellent mechanical properties, superior thermal and electrical conductivity, and outstanding corrosion resistance. Among aluminum alloys, 6061-T651, 7075-T651, and 2024-T351 are widely used for their ideal balance of strength, machinability, and cost.

Plastics

PC+ABS

PC/ABS (Polycarbonate‑ABS Blend) Plastic Material PC+ABS is a blend-modified material that combines the advantages of both materials. It not only inherits the high impact resistance of PC but also the material strength of ABS, while improving its heat resistance. It is often used in electronic product casings, automotive interiors, consumer products, and more.

CPVC

CPVC (Chlorinated Polyvinyl Chloride) Plastic Material CPVC (Chlorinated Polyvinyl Chloride) is a modified form of PVC, with enhanced thermal stability, mechanical properties, and chemical resistance. These upgraded characteristics make CPVC an excellent choice for applications in high-temperature and corrosive environments where ordinary PVC would fail.

PC+GF

PC+GF(Glass‑Fiber Reinforced Polycarbonate) Material PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making

PEI

PEI (Polyetherimide) Engineering Material PEI (polyetherimide) is a high-performance thermoplastic known for excellent heat resistance, mechanical strength, and chemical stability. It is widely used in demanding applications across aerospace, electronics, medical, and industrial fields.

LDPE

LDPE Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PP

PP Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

PET

PET PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PVC

PVC (Polyvinyl Chloride) Plastic Material Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as

PMMA (Acrylic)

PMMA (Acrylic) Engineering Material Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical

PEEK

PEEK (Polyetheretherketone) Engineering Material PEEK (polyetheretherketone) is a premium thermoplastic widely recognized for its exceptional thermal stability, mechanical strength, chemical resistance, dimensional stability, and in many cases biocompatibility and electrical insulation. It is used in extreme environments like aerospace, medical implants, electronics, and semiconductor industries.

Nylon

Nylon (Polyamide) Engineering Material Nylon (polyamide) is a versatile engineering thermoplastic known for its high strength, excellent wear resistance, good chemical stability, and toughness. It is widely used across industries for gears, bearings, bushings, automotive components, industrial parts, and more. Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications

POM

POM (Polyoxymethylene / Acetal) Engineering Material POM (polyoxymethylene), also known as acetal, is a high‑performance engineering thermoplastic valued for its rigidity, low friction, excellent wear resistance, and good dimensional stability. It is often used in precision mechanical parts that require durable, low‑maintenance performance.

HIPS

HIPS (High Impact Polystyrene) Material HIPS, or High Impact Polystyrene, is a modified polystyrene polymer enhanced with rubber modifiers (usually polybutadiene) to improve toughness and durability. The result is a rigid yet impact-resistant thermoplastic that retains good processability, making it popular in prototyping, manufacturing, and consumer products. HIPS combines the stiffness of polystyrene with improved

HDPE

HDPE (High-Density Polyethylene) Material High-Density Polyethylene (HDPE) is a thermoplastic polymer with high strength-to-density ratio, known for durability, chemical resistance, and ease of processing. As a semi-crystalline plastic, it offers excellent impact performance, low moisture uptake, and good machinability — making it a popular choice in industrial, chemical, packaging, and structural applications. It is great

ABS

ABS (Acrylonitrile Butadiene Styrene) Material ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent balance of strength, toughness, and processability. Because it combines rigidity from acrylonitrile and styrene with impact resistance from butadiene, ABS is commonly used in consumer products, enclosures, housings, and structural components.

Tolerances without individual tolerance indications according to ISO 2768-1:1989. Values in millimeters.

| Basic size range | f (fine) | m (medium) | c (coarse) | v (very coarse) |

|---|---|---|---|---|

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | — |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over 2000 up to 4000 | – | ±2.0 | ±4.0 | ±8.0 |

Tolerances for CNC Machining

Horizon applies the ISO 2768-m (medium) standard for machined plastics and the ISO 2768-f (fine) standard for machined metals. Under normal circumstances, CNC machining tolerances can be controlled within the range of ±0.125 mm (±0.005″) to ±0.05 mm (±0.002″). For tighter tolerances, please provide fully detailed 2D drawings. Our engineering team will confirm the critical dimensional requirements with you and strive to achieve the highest precision possible. If 2D drawings are not available, we will apply the ISO 2768-m (medium) standard for machined parts.

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

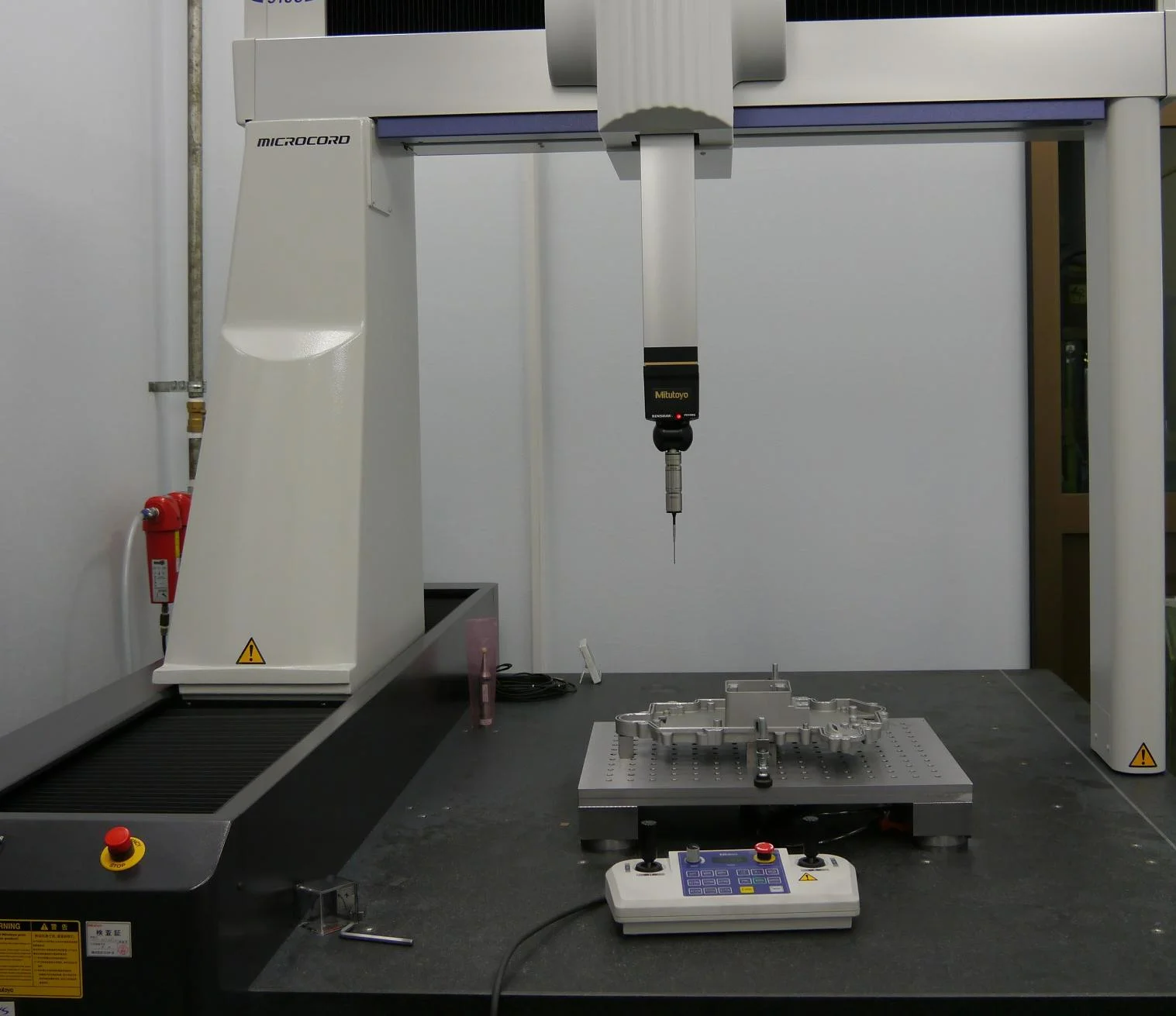

| 1 | Advanced Inspection Equipment | ||||

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

Surface Finish and Post-Processing Options

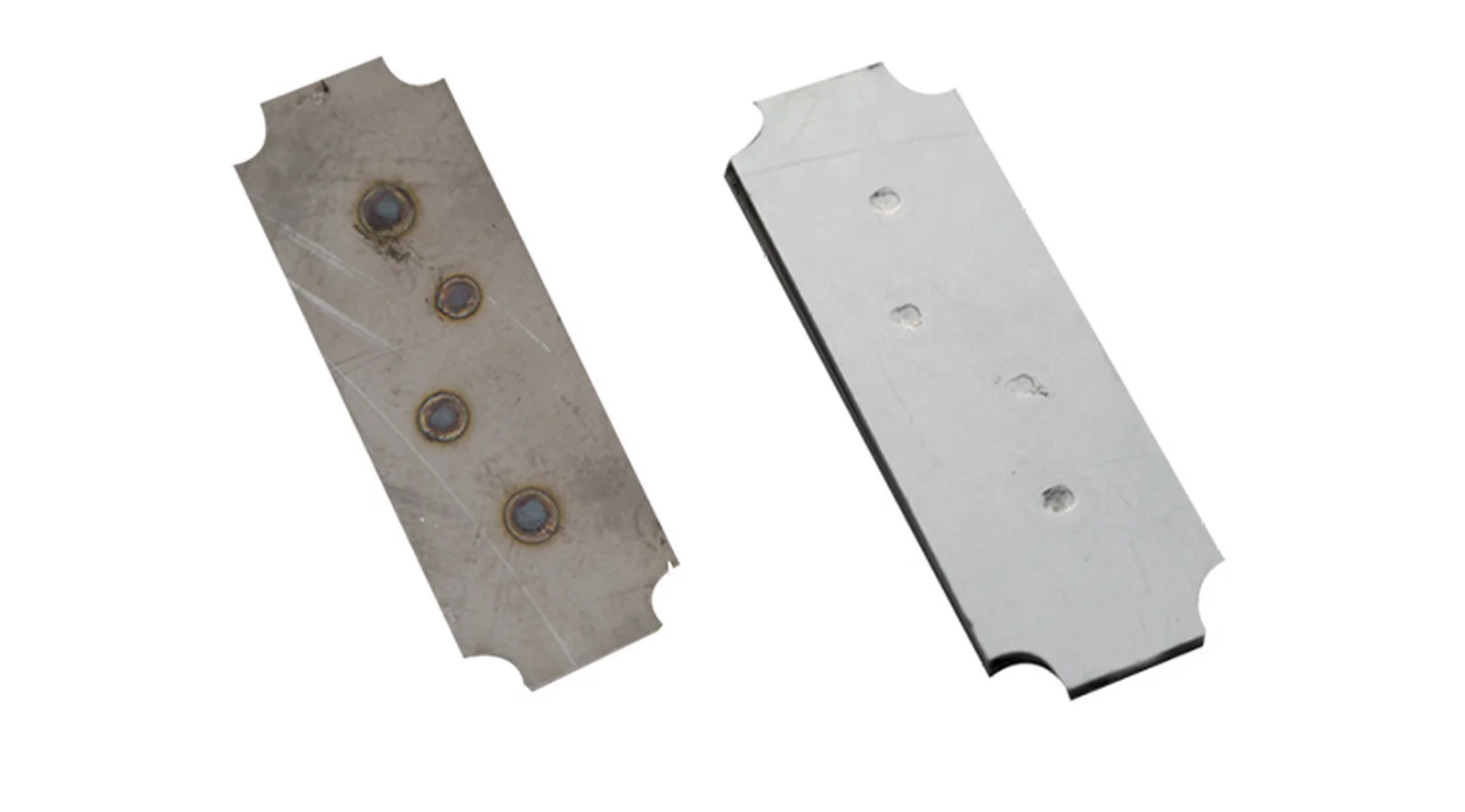

As machined

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Our CNC Turning capabilities

We offer two CNC turning options: standard (±0.1 mm) and high-precision (±0.005 mm), ensuring accuracy while maintaining cost efficiency to meet requirements from general applications to high-end products. If no 2D drawing is provided, we will default to the following standard tolerances: ISO 2768-m for CNC milled metals and ISO 2768-c for plastics.

Description

Maximum Part Size

Typically up to 500 mm in diameter and 1500 mm in length, though larger sizes can be accommodated with specific equipment.

Minimum Part Size

As small as 1 mm in diameter, depending on the material and machining setup.

General Tolerances

Standard tolerances of ±0.01 mm; tighter tolerances down to ±0.005 mm can be achieved based on the material and complexity of the part.

Lead Time

Standard lead times range from 3-7 days for small batches. Expedited services are available, reducing lead time to 24-48 hours depending on part complexity and material availability.

What is CNC Turning?

CNC turning is a subtractive manufacturing process in which a metal rod is rotated while a cutting tool is precisely applied to the workpiece surface to remove excess material and form the final part. Our CNC lathes are equipped with live tooling, enabling the machining of flat features and holes, as well as both outside diameter (OD) and inside diameter (ID) threading.

Finished turned parts can be left with their original machined surface (with visible tool marks) or bead blasted for a more uniform texture. Once the production run is complete, all parts undergo strict inspection, are carefully packaged, and promptly shipped.

Customer Success Stories

Crafted with precision and intelligence for beautiful, durable products.

Smart Home Industry

A Bespoke Pendant Light: Crafting Perfection Through Innovation and Dedication

Home & Décor Industry