Why Choose Horizon Overmolding?

Overmolding is a manufacturing process where one material is molded over or around another, creating a single seamless part. It enhances functionality, comfort, and durability, while allowing multi-material designs in a wide range of products—from grips and handles to medical devices and automotive components.

Advantages of Overmolding

How to Work With Us

Upload a CAD File

To start, simply select a manufacturingprocess and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we’ll send you designfor manufacturability(DFM) analysis andreal-time pricing.

Manufacturing Begins

Once you review your quote and placeyour order, we’ll start the manufacturingprocess. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allowsus to produce parts in as fast as 1 day.

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

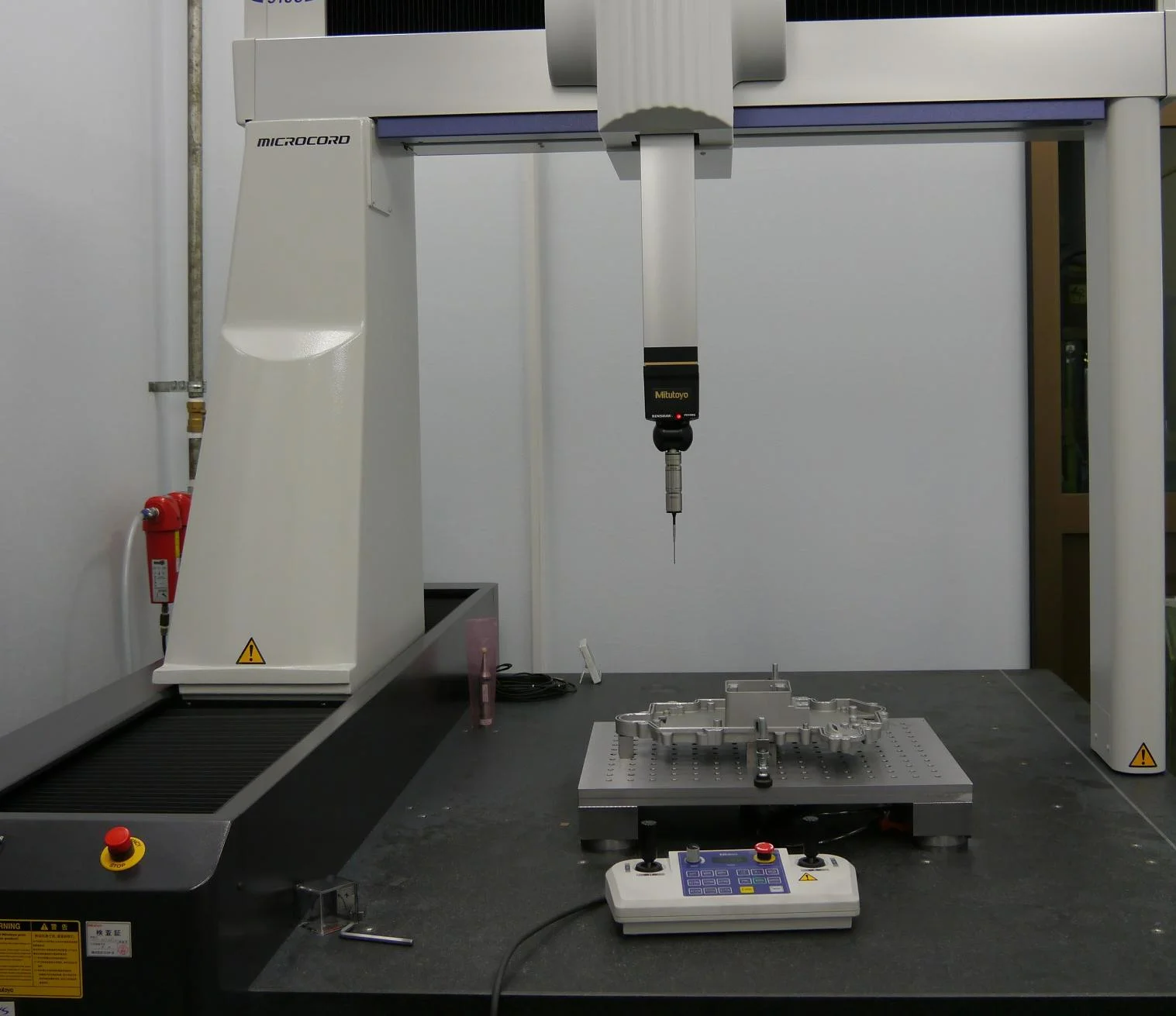

| 1 | Advanced Inspection Equipment | ||||

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

What is overmolding?

At Horizon, we specialize in plastic overmolding technology — enabling your products to achieve a perfect balance of performance and aesthetics.

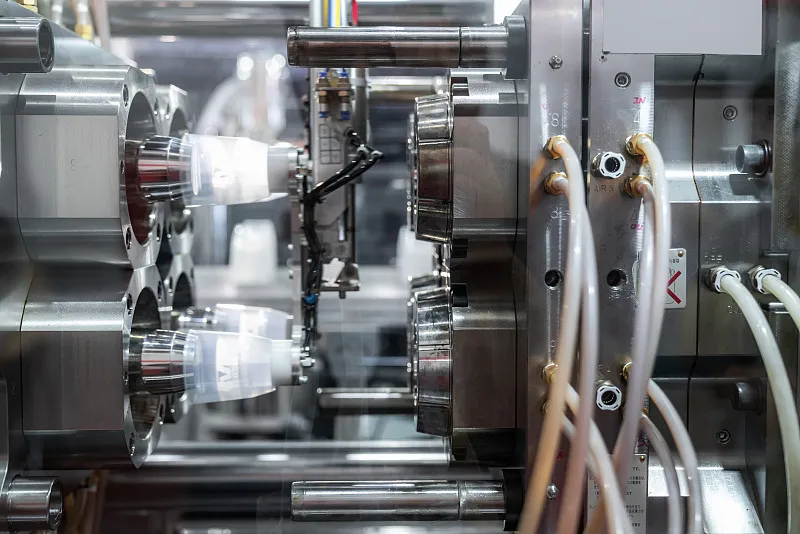

Overmolding is an advanced injection molding process that combines two or more thermoplastic materials into a single, unified structure. By precisely molding a secondary material over a substrate, we create seamless integration of different textures, colors, or functions.

This process greatly enhances a product’s durability, grip, and tactile feel, while elevating its visual appeal and brand distinction. Overmolding is widely applied in industries such as automotive, medical devices, and consumer electronics, where high performance and refined design are equally important.

With a professional engineering team and state-of-the-art molding equipment, Horizon provides fully customized overmolding solutions—from material selection and mold design to mass production. Every step is carried out with precision and consistency.

Contact us today to discover how we can help you create smarter, stronger, and more beautiful products through advanced overmolding technology.

Expanded injection molding capabilities

Plastic Injection Molding

Plastic injection molding is a manufacturing process where molten plastic is injected into a mold under high pressure, then cooled to form the desired part. It precisely reproduces complex designs and is widely used in consumer electronics, automotive components, medical devices, and more.

Liquid Silicone Rubber Molding

Liquid Silicone Rubber (LSR) Molding is a manufacturing process where liquid silicone is injected into a heated mold, then cured to form flexible, durable, and high-precision parts. It enables the production of complex geometries with excellent biocompatibility, heat resistance, and electrical insulation. LSR molding is widely used in medical devices, automotive components, consumer products, and electronic applications.

Insert Molding

Insert molding is a manufacturing process where metal or other components are placed into a mold, and plastic is molded around them to create a single, unified part. This process improves strength, precision, and durability, while enabling complex assemblies in a wide range of products—from electronics and automotive parts to medical devices and consumer goods.

CNC Machining for Various Industrial Applications

Consumer Electronics

Prototyping and on-demand production of consumer electronics products.