Innovative Companies We Support

Horizon’s Urethane Casting Services

We are fully equipped to meet all your vacuum casting and silicone molding needs. With years of industry experience, we can manufacture your plastic parts to the highest standards, efficiently, cost-effectively, and with fast turnaround.

Vacuum casting is an ideal method for producing rigid or flexible parts, perfectly suited for high-precision prototype creation, functional testing, concept validation, and presentation demonstrations. Polyurethane cast parts can be customized in quantities ranging from just a few pieces to several hundred, meeting a wide range of requirements.

To learn more about our casting services, contact us today.

why choose Vacuum Casting with Horizon?

1

Comprehensive Material Solutions

Offering a variety of materials, including silicone, ABS-like, and POM-like options.

2

Precision & Reliability

Tolerances from ±0.1mm to ±0.8mm, smooth surface finishes, and expert mold-making for consistent quality.

3

Fast & Flexible Delivery

Parts delivered in 5–15 days, cost-effective low-volume production.

How to Work With Us

How to Work With Us

Our ordering process

Vacuum Casting Materials

Silicone

Silicone Flexible, durable, and heat-resistant, built to last without losing shape. Food-grade silicone Safe, non-toxic.

- Shore A 10-30: Very soft

- Shore A 40-50: Medium hardness

- Shore A 50-60: High hardness

Rubber

Excellent elasticity, wear- and tear-resistant, adaptable to complex shapes.

- T0387:Adjustable hardness (Shore A35–80), soft and Clear.

- TPU8400:Adjustable hardness (Shore A35–80), easy to color, high strength.

PP-like

Lightweight and flexible, ideal for parts requiring bending or snapping functionality.

- 5690/8570:High-strength, impact-resistant, ideal for electronic housings.

ABS-like

High-quality general-purpose plastics are commonly used to make enclosures, brackets, and structural components.

- PU8150:Combines wear resistance and oil resistance, suitable for small-batch production and rapid prototyping, and can be used as a substitute for ABS.

PMMA-like

Wear-resistant with good rigidity, dimensional stability and impact resistance, suitable for complex parts with excellent performance.

- PX5210: High transparency and weather-resistant, ideal for outdoor parts and covers.

- PX100: Tough and impact-resistant, suitable for rapid prototyping and functional parts.

Nylon-like

Slightly elastic with excellent wear resistance. It is commonly used in structural parts requiring strength.

- 2180:Combines strength and corrosion resistance, suitable for functional gear components.

POM-like

The material is hard and dimensionally stable, commonly used in parts requiring mechanical fitting.

- XU-50:High strength, wear-resistant, and heat-resistant, suitable for functional components such as gears and slide rails.

PC-like

PC-like materials combine dimensional stability and high strength, making them suitable for small-batch functional and appearance verification parts.

- PX527:Transparent resin with excellent impact resistance, suitable for producing high-quality transparent parts.

Vacuum Casting Finish

Horizon’s vacuum casting process offers SPI and VDI surface texture finishes. If your part requires painting, please confirm with our customer service team before ordering to ensure the desired gloss effect. For detailed information on SPI and VDI finishes, please refer to the following content.

SPI

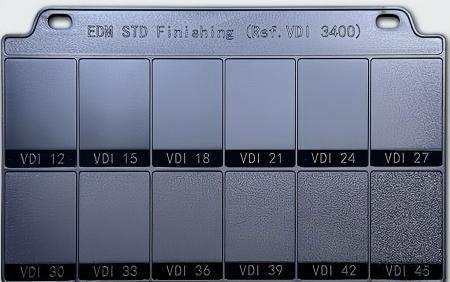

VDI

VDI Finish: Created by sandblasting or etching the mold surface, providing textures ranging from fine matte to coarse grain. Suitable for parts that require tactile feel, functional surface properties, or reduced light reflection.

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

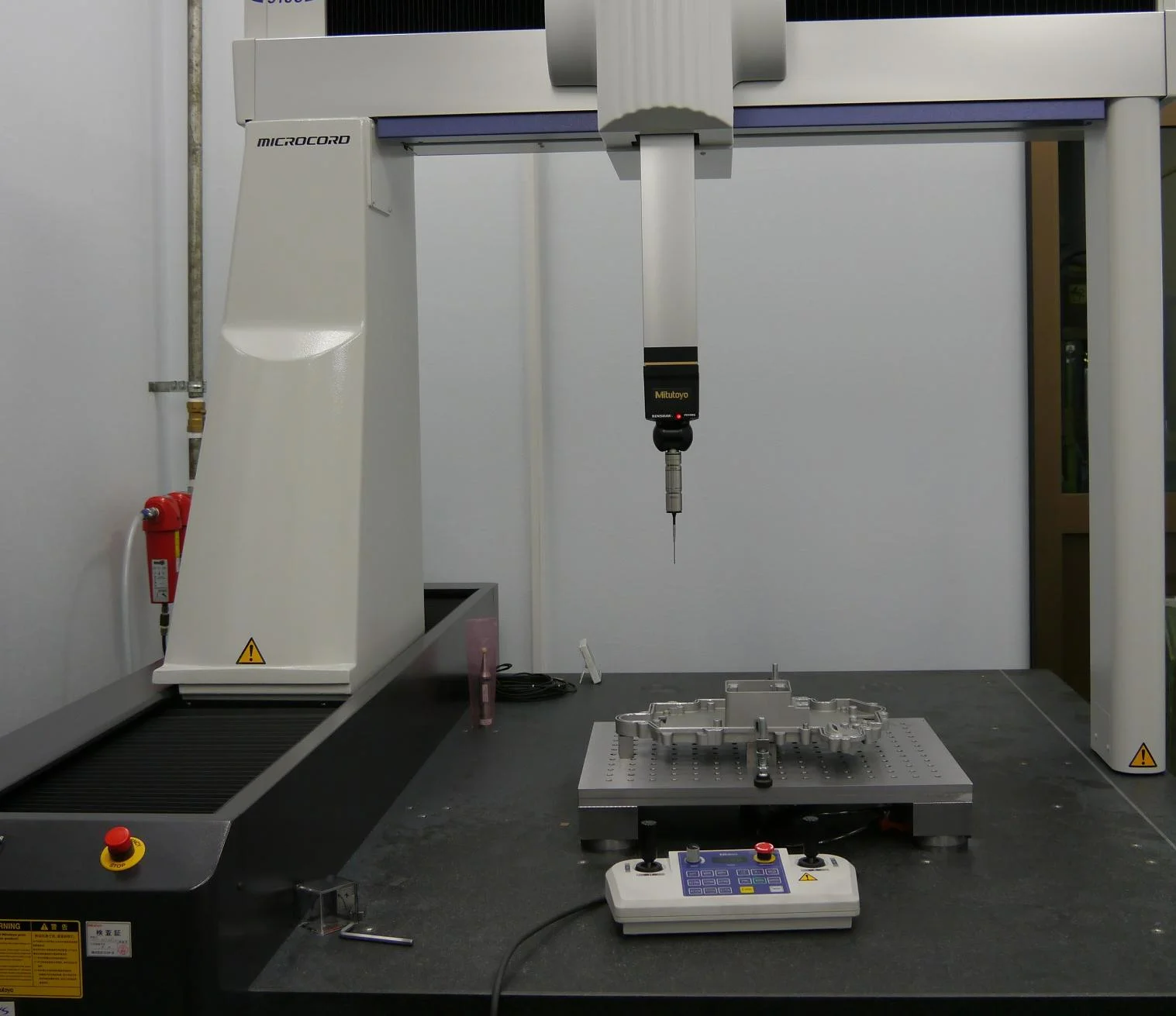

| 1 | Advanced Inspection Equipment | ||||

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

3D Printing vs. Vacuum Casting vs. Injection Molding

Different manufacturing processes serve different needs: 3D printing offers flexibility and speed, ideal for rapid prototyping and low-volume production. Vacuum casting balances cost and surface quality, making it suitable for small to medium batches. Injection molding excels in large-scale production, delivering high precision and consistency. By comparing these three processes, you can identify the manufacturing solution that best fits your project.

| 3D Printing | Vacuum Casting | Injection Molding | ||

|---|---|---|---|---|

| Cost | $0.00 | $400-2,000 | $5,000+ | |

| Precision | ±0.1~0.3 mm | ±0.1~0.8 mm | ±0.05~0.1 mm | |

| Surface Quality | Some 3D printing methods typically produce rough surfaces | high gloss and fine appearance | Offers high surface precision and consistency | |

| Lead Time | 1~3 days | 5~15 days | 4weeks + | |

| Design Flexibility | Design flexibility allows several versions in a single day | Economical alternative to injection molding | Design changes incur high mold adjustment costs. | |

| Material Options | Plastics, resins, some metals | Polyurethane, epoxy, etc. | Thermoplastics, some engineering plastics | |

| Typical Applications | Rapid prototyping, concept validation, low-volume custom parts | Small to medium batch custom parts, functional prototypes, premium appearance parts | Large-scale production, structural components, functional parts |

What is Vacuum Casting?

Vacuum casting is an efficient molding process that uses vacuum pressure to draw liquid resin into silicone molds, accurately replicating the details of the master pattern. Unlike traditional injection molding, it effectively removes air bubbles under vacuum, ensuring smooth surfaces and precise structures—ideal for complex geometries, undercuts, and high-quality appearance parts.

The master pattern can be created through CNC machining or 3D printing, then used to produce silicone molds for casting. Each silicone mold can typically be reused around 20 times, enabling the rapid production of stable and accurate parts. Vacuum casting is the perfect solution for rapid prototyping, small-batch production, and market testing, offering efficiency, cost-effectiveness, and excellent quality.