This exquisitely crafted pendant light is a bespoke creation tailored to the discerning needs of our international client. The specifications set were nothing short of exacting. Each individual lamp piece was required to be incredibly thin, yet simultaneously achieve an unparalleled level of light transmittance, a combination that presented a significant engineering challenge.

Client Specifications & Challenge:

The initial client request sets a high bar for the project—requiring thin lamp pieces with excellent light transmittance. This is a realistic challenge as both factors (thinness and high transmittance) typically conflict in lighting design.

The necessity for an elegant and stable design while dealing with such thin components is a reasonable consideration for bespoke lighting design.

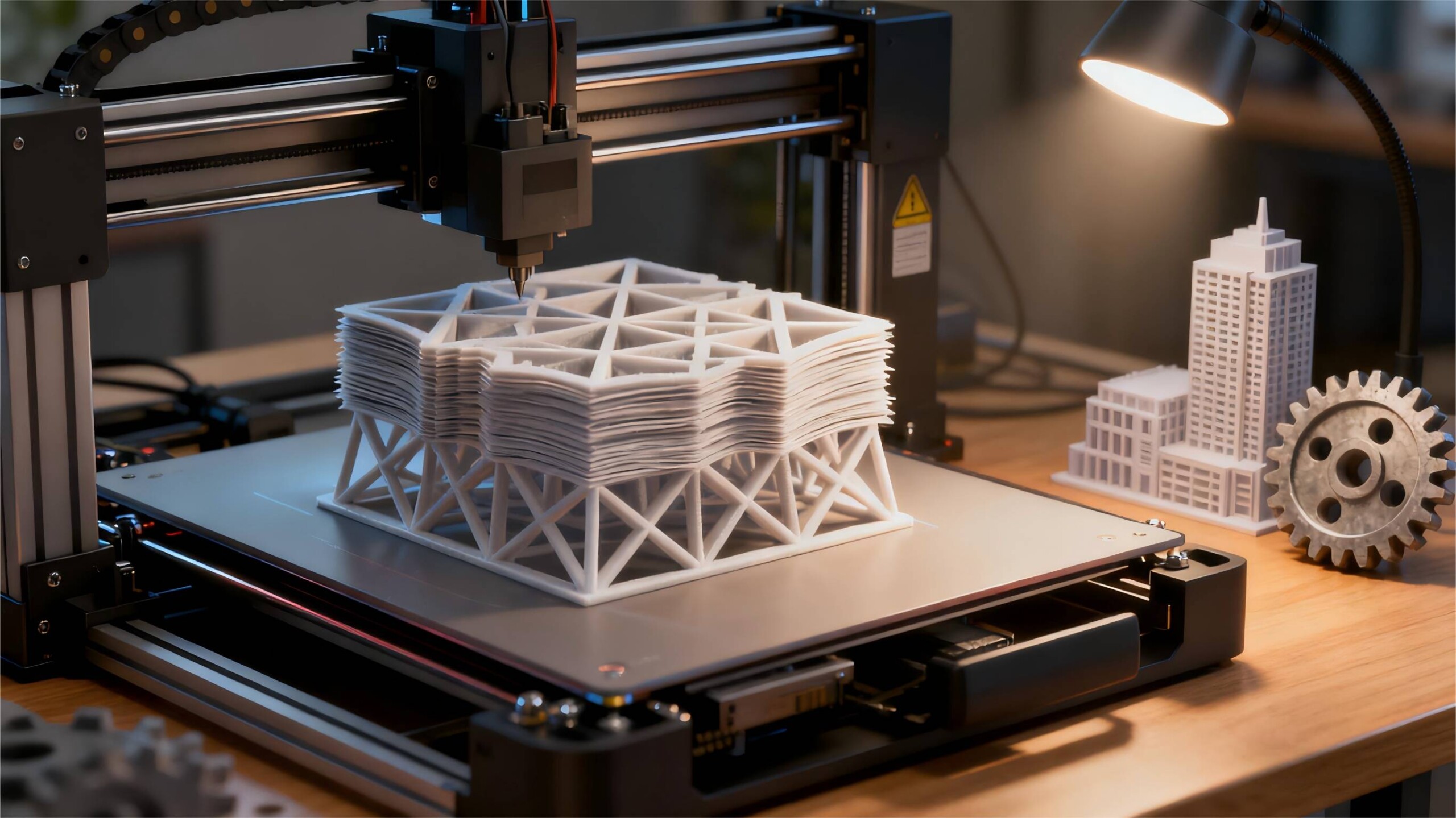

Engineering & Structural Optimization

During the production journey, our team was confronted with a series of complex obstacles. Central to these were the intricate tasks of optimizing both the product structure and the mold structure. The product structure needed to balance the fragility of the thin lamp pieces with the overall stability and aesthetic integrity of the pendant light. Our engineers painstakingly analyzed and redesigned every aspect, ensuring that the light would not only look stunning but also withstand the rigors of daily use.