Rapid CNC Machining

CNC machining is ideal for prototype parts that need functional testing using final production materials. At 3ERP, we operate a broad range of CNC machining centers, including mills and lathes (for CNC turning), enabling fast and reliable production. We support a broad selection of materials and finishes, and can also combine CNC machining with other processes for greater flexibility.

CNC machining is one of the most precise fabrication methods available. While it prioritizes quick turnaround over ultra-tight tolerances, the output quality remains high.

CNC machining offers fast turnaround for small-batch production, producing parts that are often nearly production-grade. Although typically more expensive than 3D printing, CNC parts provide an excellent surface finish and superior mechanical strength.

How to Work With Us

Upload a CAD File

To start, simply select a manufacturingprocess and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we’ll send you designfor manufacturability(DFM) analysis andreal-time pricing.

Manufacturing Begins

Once you review your quote and placeyour order, we’ll start the manufacturingprocess. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allowsus to produce parts in as fast as 1 day.

Find the Perfect Rapid Prototyping Solution for Your Project

Choosing the right rapid prototyping method is essential to bringing your ideas to life quickly and efficiently. Depending on your project’s requirements—such as material, precision, functionality, and production volume—different techniques offer unique advantages and trade-offs. Here’s a quick overview of the most popular rapid prototyping methods:

technology

Advantages

Disadvantages

3D Printing

Delivers speed and cost-efficiency while enabling highly complex geometries beyond the reach of other techniques.

While offering flexibility, material properties may not replicate traditional parts exactly, and resolution depends on the specific technology employed.

CNC Machining

High precision and compatible with a wide range of materials, ideal for producing functional and durable parts.

Higher cost and longer lead times compared to some additive manufacturing methods.

Vacuum Casting

Fast and cost-effective, ideal for small-batch production, capable of replicating high-precision details with a realistic appearance.

Material properties are limited, with finished parts offering lower strength and durability compared to injection-molded or CNC-machined components.

Injection Molding

Engineered for large-scale production, delivering both cost-effective solutions and end-use parts with exceptional detail and full functionality.

High upfront tooling costs can make small-volume production less economical.

Sheet Metal Fabrcation

Enables the creation of durable, easily modifiable prototypes, perfectly bridging the gap between prototyping and production.

Best suited for simpler designs, as highly intricate or detail-intensive parts may exceed its complexity limits.

Quality Assurance

| Driven by excellence, we embed quality into every detail—from advanced tools to rigorous standards. We ensure consistent, outstanding quality. | |||||

|---|---|---|---|---|---|

| 1 | Advanced Inspection Equipment | ||||

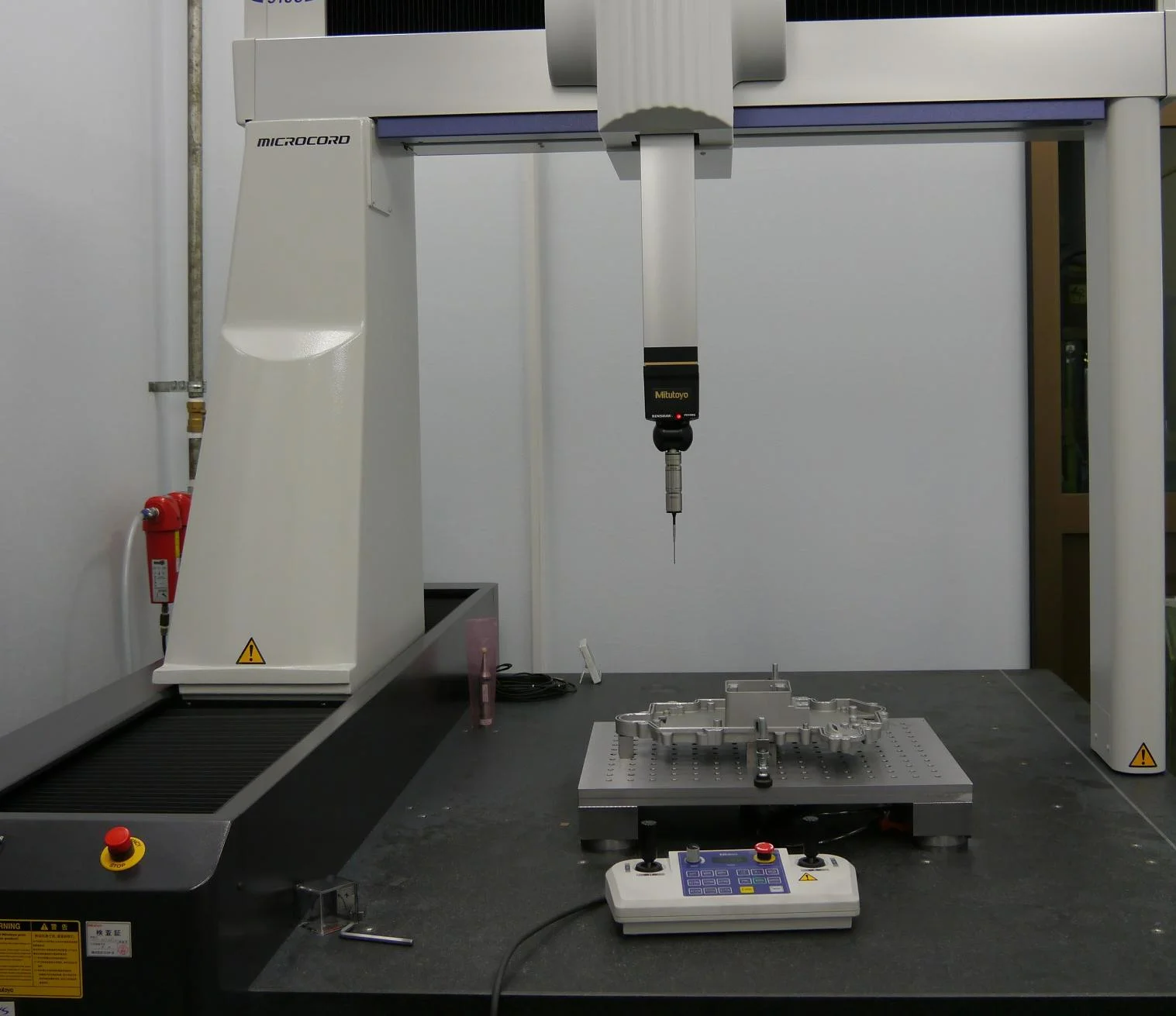

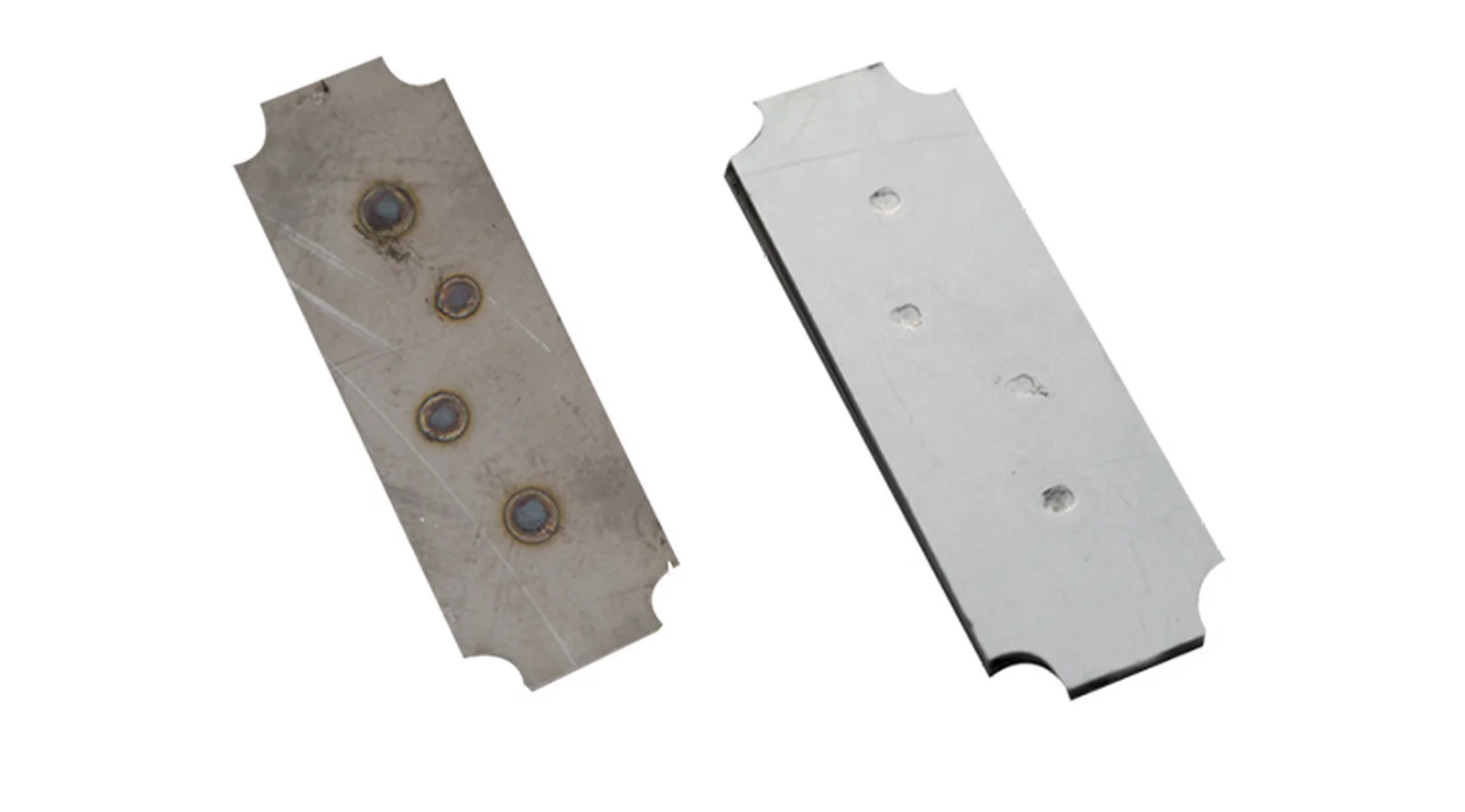

| We employ professional inspection equipment for precise measurement and validation. A spectrometer analyzes metal composition, a 2.5D measuring instrument verifies detailed features, a coordinate measuring machine (CMM) inspects complex three-dimensional structures, and height gauges ensure the accuracy of fundamental dimensions. | |||||

| 2 | Strict quality management system | ||||

| From first article inspection to in-process checks and final pre-shipment testing, every stage is governed by a rigorous management system to ensure consistent quality. | |||||

| IQC(Incoming Quality Control) | FAI (First Article Inspection) | ||||

| IPQC(In-Process Quality Control) | CMM inspection report | ||||

| FQC(Final Quality Control) | DIR(Dimensional Inspection Report ) | ||||

| OQC(Outgoing Quality Control) | CAR(Corrective and Preventive Action Report) | ||||

| Material Certificates | ISO 9001 | ||||

Why Choose Horizon for

Rapid Prototyping Services?

Rapid Prototyping Services?

Rapid Delivery, Gain Market Advantage

With our efficient processes, we deliver prototypes quickly, significantly shortening development cycles and getting your products to market faster—keeping you one step ahead.

Exceptional Quality, Trusted Reliability

Horizon uses advanced materials and precision manufacturing, strictly adhering to industry standards. Every prototype is crafted to perfection, ensuring top-tier quality.

Professional Engineering Support, Empowering Innovation

Our engineering team provides full support—from design optimization to solving technical challenges—ensuring smooth and efficient prototype development, turning your ideas into reality with ease.

Rapid Prototyping Materials

Metal

Inconel

Inconel Superalloy Materials

Magnesium

Magnesium & Magnesium Alloy Materials

Titanium

Titanium

Stainless Steel

Stainless Steel Material & Alloys

Copper

Copper Material & Copper Alloys

Brass

Brass Material & Brass Alloys

Aluminum

Aluminum Material & Aluminum Alloys

Plastic

TPU

Thermoplastic Polyurethane (TPU) For Injection Molding

HorizonRP offers high-quality Thermoplastic Polyurethane (TPU) material, known for its flexibility, durability, and resistance to abrasion and chemicals. Ideal for CNC machining applications, TPU is widely used across various industries, including automotive, medical, and consumer electronics.

PC+ABS

PC/ABS (Polycarbonate‑ABS Blend) Plastic Material

PC+ABS is a blend-modified material that combines the advantages of both materials. It not only inherits the high impact resistance of PC but also the material strength of ABS, while improving its heat resistance. It is often used in electronic product casings, automotive interiors, consumer products, and more.

CPVC

CPVC (Chlorinated Polyvinyl Chloride) Plastic Material

CPVC (Chlorinated Polyvinyl Chloride) is a modified form of PVC, with enhanced thermal stability, mechanical properties, and chemical resistance. These upgraded characteristics make CPVC an excellent choice for applications in high-temperature and corrosive environments where ordinary PVC would fail.

PC+GF

PC+GF(Glass‑Fiber Reinforced Polycarbonate) Material

PC+GF (polycarbonate + glass fiber reinforced composite material) is a reinforced engineering plastic made by adding glass fiber (abbreviated as GF) to a polycarbonate (PC) matrix. The addition of glass fiber can significantly improve the mechanical properties and stability of pure PC while retaining some of PC’s excellent inherent properties, making it suitable for scenarios with high requirements for strength, rigidity, and dimensional accuracy. It features high strength, high rigidity, and heat resistance, and is ideal for automotive parts, electrical enclosures, and structural components.

PEI

PEI (Polyetherimide) Engineering Material

PEI (polyetherimide) is a high-performance thermoplastic known for excellent heat resistance, mechanical strength, and chemical stability. It is widely used in demanding applications across aerospace, electronics, medical, and industrial fields.

PTFE

PTFE

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer. It is frequently used in mechanical components requiring reduced friction and wear—such as bearings, gears, and piston rings—due to its non-stick properties, low friction characteristics, and self-lubricating capabilities. PTFE also exhibits excellent electrical insulation properties, making it highly suitable for applications like high-frequency cables, high-voltage insulators, and electronic components.

Additionally, PTFE maintains stable performance during long-term use across an extreme temperature range from -200°C (ultra-low temperature) to 260°C (high temperature), enabling its use in harsh environments such as aerospace systems, deep-sea equipment, and high-temperature industrial apparatus.

LDPE

LDPE

Low-Density Polyethylene (LDPE) is lighter than water, soft and tough, with excellent acid and alkali resistance as well as electrical insulation properties. It is widely used in fields such as packaging, agriculture, electronics, and daily necessities.

PP

PP (Polypropylene) Engineering Material

Polypropylene (PP) is a well-balanced thermoplastic characterized by lightweight material, excellent chemical resistance, and good flexibility. Owing to these properties, it finds wide application in fields such as packaging, household appliances, automotive, daily necessities, and medical devices.

PET

PET

PET (polyethylene terephthalate) is a common thermoplastic polyester with excellent mechanical properties and strong chemical resistance. It also offers glass-like transparency and luster, with a high light transmittance of about 88–92%, and is widely used in beverage bottles, food packaging, and engineering plastics.

PVC

PVC (Polyvinyl Chloride) Plastic Material

Polyvinyl chloride (PVC) is a widely used thermoplastic polymer material characterized by excellent mechanical properties, outstanding corrosion resistance, and superior electrical insulation performance. By incorporating various additives, it can be tailored to meet customized requirements. Owing to its unique combination of properties, PVC finds extensive applications in fields such as construction, industry, packaging, and healthcare.

PC

PC (Polycarbonate) Engineering Material

PC (polycarbonate) is a versatile engineering plastic known for its high impact resistance, optical transparency, and good thermal stability. It combines toughness, heat resistance, and aesthetic clarity, making it suitable for a wide array of applications.

PMMA (Acrylic)

PMMA (Acrylic) Engineering Material

Acrylic (also known as polymethyl methacrylate, PMMA) boasts not only excellent optical performance but also outstanding UV resistance. With a light transmittance of up to 92%—comparable to glass—it has become a popular material in scenarios ranging from neon signs in shopping malls and display case panels in museums to precision optical lenses and stage light covers.

PEEK

PEEK (Polyetheretherketone) Engineering Material

PEEK (polyetheretherketone) is a premium thermoplastic widely recognized for its exceptional thermal stability, mechanical strength, chemical resistance, dimensional stability, and in many cases biocompatibility and electrical insulation. It is used in extreme environments like aerospace, medical implants, electronics, and semiconductor industries.

Nylon

Nylon (Polyamide) Engineering Material

Nylon (polyamide) is a versatile engineering thermoplastic known for its high strength, excellent wear resistance, good chemical stability, and toughness. It is widely used across industries for gears, bearings, bushings, automotive components, industrial parts, and more.

Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications in the automotive, aerospace, and medical industries. With its remarkable combination of properties, nylon stands out as a versatile and reliable material for a diverse range of CNC machining applications.

POM

POM (Polyoxymethylene / Acetal) Engineering Material

POM (polyoxymethylene), also known as acetal, is a high‑performance engineering thermoplastic valued for its rigidity, low friction, excellent wear resistance, and good dimensional stability. It is often used in precision mechanical parts that require durable, low‑maintenance performance.

HIPS

HIPS (High Impact Polystyrene) Material

HIPS, or High Impact Polystyrene, is a modified polystyrene polymer enhanced with rubber modifiers (usually polybutadiene) to improve toughness and durability. The result is a rigid yet impact-resistant thermoplastic that retains good processability, making it popular in prototyping, manufacturing, and consumer products.

HIPS combines the stiffness of polystyrene with improved impact performance, offering a cost-effective balance of mechanical and processing properties.

HDPE

HDPE (High-Density Polyethylene) Material

High-Density Polyethylene (HDPE) is a thermoplastic polymer with high strength-to-density ratio, known for durability, chemical resistance, and ease of processing. As a semi-crystalline plastic, it offers excellent impact performance, low moisture uptake, and good machinability — making it a popular choice in industrial, chemical, packaging, and structural applications. It is great for applications such as orthotic and prosthetic devices, water storage, and tanks.

ABS

ABS (Acrylonitrile Butadiene Styrene) Material

ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent balance of strength, toughness, and processability. Because it combines rigidity from acrylonitrile and styrene with impact resistance from butadiene, ABS is commonly used in consumer products, enclosures, housings, and structural components.

Surface Finish and Post-Processing Options

As machined

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Electroless Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Chrome Plating

Chrome plating is widely used in various industries, which not only enhances the beautiful appearance of the product, but also improves the performance of the product, such as corrosion resistance, oxidation resistance, abrasion resistance, hardness, etc.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.